Lab4

Lambda : Reading Phototransistors on ADC Inputs: Logic for Rotation to Light

Source

Background: Here

you will use the two DAC channels on the 6024E card to send analog signals to

the MSP430 microcomputer. The analog signals will simulate the output of two phototransistors.

It will be imagined that PNZ150 phototransistors are responding to a distant light

source, as they did in Lab 2. Based on the sum and difference of the two analog

signals, the code will orient the (simulated) rover to point toward the light.

In essence, the phototransistor signals will act as FEEDBACK for the rover navigation

to knock over block under the lamp.

(You

are required here only to upgrade Lab4pre to handle analog IN and demo on the

LabVIEW exercise VI that your code logic works to respond properly to phototransistor

signals difference and sum.)

Requirements:

You must use an MSP430F1232 chip on the demo board; it will support the

successive approximation A-D conversion the code will be expecting.

(1)

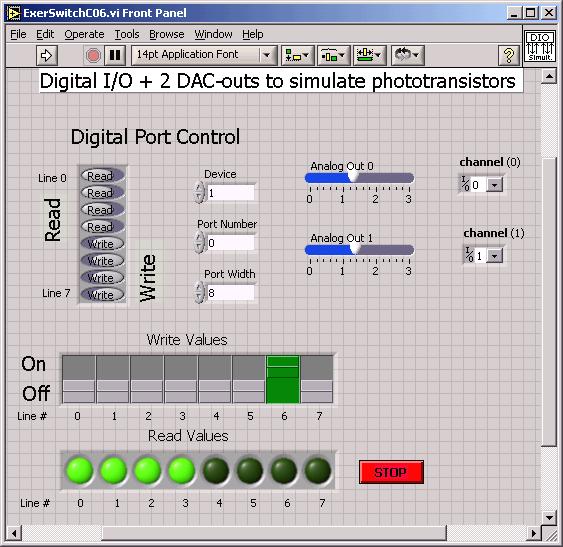

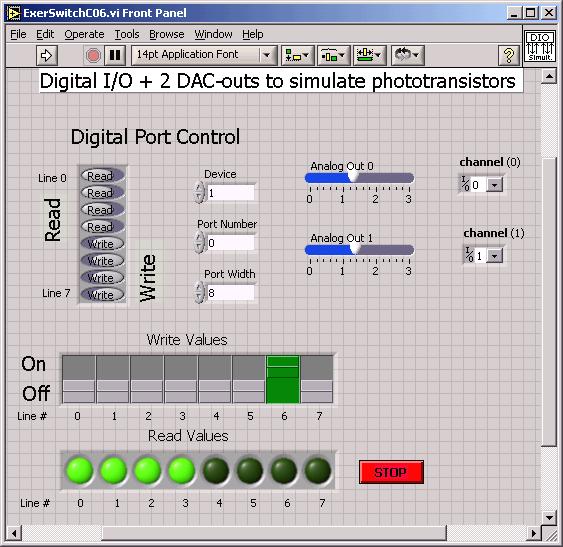

"Upgrade" your Lab4pre to add two analog-out sliders: See suggestion:

the sliders will have a range of 0-3volts, since the MSP430 will recognize

analog signals of no greater than 3v magnitude.

The

LEDs L0 to L3 represent what they did in Lab4pre:

L0

ON left wheel going forward; L0 OFF left wheel in reverse

L1 ON right wheel

going forward

L2 ON left motor turned ON; L2 OFF left motor inhibited

L3

ON right motor turned ON

The

switches D4-D6 act the same as they did in Lab4pre:

D4

ON implies rover is in contact with left wall

D5 ON implies rover is in contact

with right wall

D6 ON means the timed loop is activated inside the infinite

loop of the code.

(Flick D6 so the rover goes through only one cycle of 40

sec or so)

(2) Copy and rename the distribution

source code Lab4C06.c. Find modifed code in IAR 4.0 "workbench". The

following code to accommodate two channels of A-D conversion in the MSP430F1232

is added in

a version of Lab4pre default code are in source

code

Lab4C06.c, in

the EN123 IP

First, near the top of main()

declare

int photoL, photoR, thet_diff_LO, thet_diff_HI, thet_summ_LO,

thet_summ_HI;

signed int diff, summ;

These lines declare variables for the A-D conversion.

Second, just after the line

that has as a comment //stop Watchdog Timer enter

ADC10CTL0 = SREF_1+ ADC10SHT_2 + REFON + REF2_5V + ADC10ON

+ ADC10IE;

// ADC10ON, interrupt enabled, 2.5v reference

ADC10AE |= 0x03;

these lines help setup

the ADC registers.

Next you need to add, just

after entering the timed loop code,

ADC10CTL0 &=

~ENC; // have to disable ADC10 to change channel

ADC10CTL1= INCH_1; // ADC10MEM reads from A1, right side

ADC10CTL0 |= ENC + ADC10SC; // Sampling and conversion start

_BIS_SR(CPUOFF + GIE); // LPM0, ADC10_ISR will force exit

photoR = ADC10MEM; //record digital A1 into storage photoR

ADC10CTL0

&= ~ENC; // have to disable ADC10 to change channel

ADC10CTL1=INCH_0; ///ADC10MEM reads from A0, left side

ADC10CTL0 |= ENC + ADC10SC; // Sampling and conversion start

_BIS_SR(CPUOFF + GIE); // LPM0, ADC10_ISR will force exit

photoL = ADC10MEM; //record digital A0 into storage photoL

diff = photoL - photoR; // difference of photoxsistors

summ = photoL + photoR; // sum of photoxsistors

this code acquires the

two analog inputs and assigns their digital values to photoL and photoR.

Finally at the end of the

code, after the last curly bracket of main, add

#pragma

vector=ADC10_VECTOR

__interrupt void ADC10_ISR (void)

{

_BIC_SR_IRQ(CPUOFF); // Clear CPUOFF bit from 0(SR)

}

which is "magical

code" taken from a TI sample of how to carry out succ. approx A-D conversion.

It is basically an interrupt that starts the actual conversion.

Make sure you hit "Rebuild

All" frequently as you add this code...The A-D conversion won't run without

the last magical lines, so don't worry if a test on your board stalls without

the last lines above...

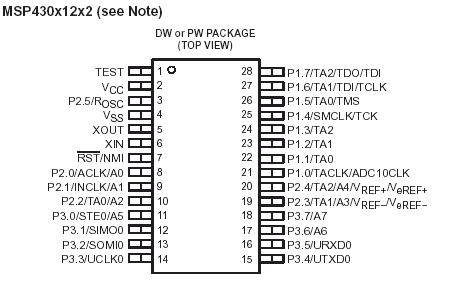

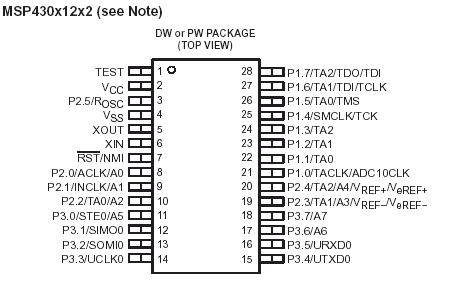

Note: The two A-D conversion

inputs are port 2.0 and 2.1 = pins 8 and 9 on the MSP430F1232 chip:

(3) As you remember from Lab4pre, a test of your VI will mean connections

on a NI green board of

DI/O 0 to DI/O 4

DI/O 1 to DI/O 5

DI/O 2 to DI/O 6

DI/O 3 to DI/O 7

To

test your "exercise" VI, declare (with switches) that bits 0-3 are

READ and 4-7 are WRITE.

and

After

testing use the 1232

demo board wired up the a green connector card now

sending LabVIEW DAC-out screw terminals 21 and 22 to MSP430 analog-in channels

P2.1 (pin 9) and P2.0 (pin 8. Check that the sliders are work to change a voltage

from 0 to 3v.

Reasonable threshold values,

in hex:

thet_diff_LO

= -0x04F; // or use 2's complement form for negative...

thet_diff_HI = 0x04F;

thet_summ_LO = 0x03F;

thet_summ_HI = 0x5FF;

2008:

actually, we will want thet_summ_LO to be represented by the hex code for 1

volt

and thet_summ_HI to be represented by the hex code for 4=2+2 volts...

(4) Next, modify code inside

your pp < pp_max timing loop such that (in psuedocode):

(i) If summ < thet_summ_LO

then

the simulator behaves just as it did for Lab4pre:

goes forward by default or turn when it hits a wall...

(this is the state of being too far away from the light source to care...)

(ii) If summ > thet_summ_LO

&& summ <thet_summ_HI

then

(iii) if diff < thet_diff_LO

(a negative number) then

(iv) turn CW until diff

> thet_diff_LO

&& diff

< thet_diff_HI

ELSE

(v)

If diff >thet_diff_HI

then

(vi) turn CCW until diff

> thet_diff_LO

&& diff

< thet_diff_HI

ELSE

(vii)

then go forward toward the light

(viii) if summ > thet_summ_HI

have

simulator

behave just as it did for Lab4pre

going forward unless it hits a wall...

(state of being too close to the light to make proper judgement...)

As

you make make the improvements above, frequently "Rebuild All". When

finished download the code into the MSP430F1232 using the DEBUG command. Either

single step through to debug or start and stop the debugging to test your code

in the VI exercise simulator.

You

may want to make sure you see the following connections of LabVIEW connector card

to MSP430 demo board:

D0 screw 52

to MSP430 pin 21 (P1.0) port 1/bit 0 is the LEFT motor direc

control

D1 screw 17 to MSP430 pin 22 (P1.1) OUT:

direc control for Right stepping motor

D2 screw 49 to MSP430 pin 17

(P3.6) output to inhibit motor,

Left

D3 screw 47 to MSP430 pin 18 (P3.7) " Right

D4 screw 19 to MSP430 pin 24 (P1.3) IN signal from lever

switch on rover, Left

D5 screw 51 to MSP430 pin 23 (P1.2) "

Right lever switch

D6 screw 16 to

MSP430 pin 11 (P3.0) IN signal from V-switch to start movement

sequence

D7 screw 48 to MSP430 pin 12 (P3.1)

(future wireless input) back up command

DAC-OUT-0

screw 22 to MSP430 pin 8 (P2.0) Left

phototransistor/slider

DAC-OUT-1

screw 21 to MSP430 pin

9 (P2.1) Right

phototransistor/slider

Green

GND wire of MSP430 board to pin 53 (GND) of the LabVIEW connector card.

(P1.4-7 on

the demo board are not available

to the user)

Possible FTQ: Explain how you read new analog values for the continued

testing in the logic for the light sum and difference testing. .

Free Advice: Consider describing your coding

problem as a series of STATE changes.

Consult the yellow IAR User Guide

for information about the features of the debugger, including single-stepping

through code.