|

Calibration Procedures

Data Processing

Calibration Procedures [top]

Through

the previous four-step DIY, you must be anxious to see how this simple

device can work on the sophisticated AFM system. Let's start with the demonstration by showing some of the videos I took using an optical microscope: side view , top view.

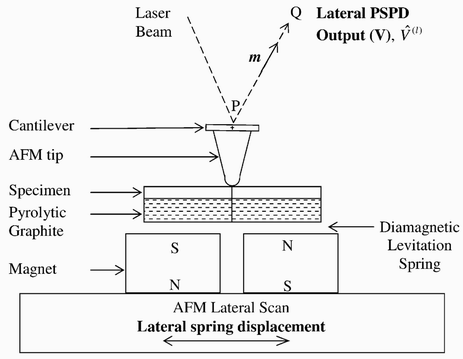

A schematic of the D-LFC is shown in Figure 7. In

the setup, the diamagnetic levitation system is

mounted on the stage of the AFM base scanner.

For the calibration, you just do the normal LFM measurement; the only

thing different is that your sample is now replaced by the D-LFC. Once

the AFM tip is engaged on the PG composite surface, the

magnets together with the AFM base are reciprocated by the lateral

scanner,

while the normal load is held fixed by

holding the normal PSPD output  constant through the

feedback controller. It

should be noticed that we used the Park Scientific Instrument AutoCP

AFM system. For those systems with a fixed sample holder but a moving

probe, the magnets are stationary while the PG sheet moves together with

the probe after the engagement. constant through the

feedback controller. It

should be noticed that we used the Park Scientific Instrument AutoCP

AFM system. For those systems with a fixed sample holder but a moving

probe, the magnets are stationary while the PG sheet moves together with

the probe after the engagement.

Figure 7. A schematic of the D-LFC

The lateral PSPD output  is recorded against the lateral base displacement is recorded against the lateral base displacement  . The displacement is related to the lateral force . The displacement is related to the lateral force  by by

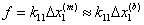

(5) (5)

where the base displacement can be decomposed  , into the displacements of the magnetic spring , into the displacements of the magnetic spring  and the AFM tip and the AFM tip  . The tip displacement . The tip displacement  is caused by the

compliance of the tip contact and the cantilever twist. It is typically within

a few nanometers while the magnetic spring displacement is on the order of tens

of micrometers. Therefore, the tip displacement can be neglected in (5). In this calibration procedure, the maximum

reciprocating displacement of the lateral base displacement is caused by the

compliance of the tip contact and the cantilever twist. It is typically within

a few nanometers while the magnetic spring displacement is on the order of tens

of micrometers. Therefore, the tip displacement can be neglected in (5). In this calibration procedure, the maximum

reciprocating displacement of the lateral base displacement  is limited to induce a

lateral force is limited to induce a

lateral force  well within the static

friction force of the onset of slip. well within the static

friction force of the onset of slip.

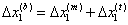

Figure 8. A diagram showing the D-LFC principles for measuring the AFM force constants

Figure 8 shows an experimental measurement of the lateral PSPD output

against the lateral displacement of the magnets on the AFM base reciprocated

within 25 µm for contact between a

mica specimen mounted on a levitated PG sheet and a spherical

bead attached near the end of an AFM cantilever.

The bead is made of boro-silicate glass coated with a 50 nm gold layer and has

a diameter of 15 µm. The experimental data show that the response is linear and

reversible within the thermal and feed-back noise band for forward and backward

scanning of the base displacement.

Step-1:

Use the D-LFC as your sample and collect the LFM data as normal.

Multiple data sets should be collected for different normal loads

(usually called set point) if you want the crosstalk force constant to

be calibrated.

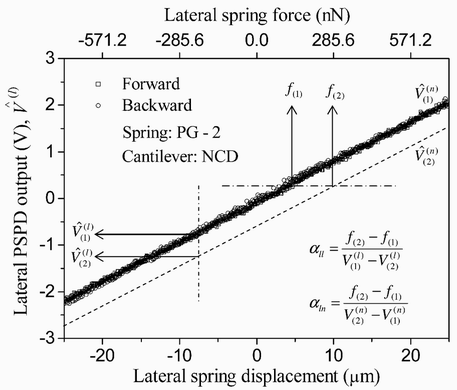

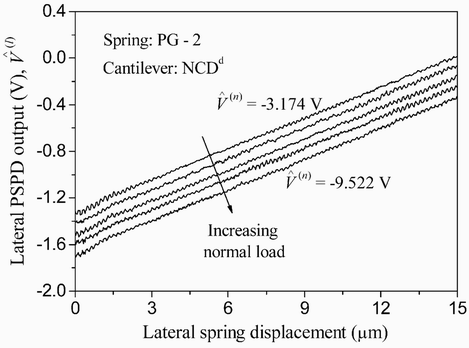

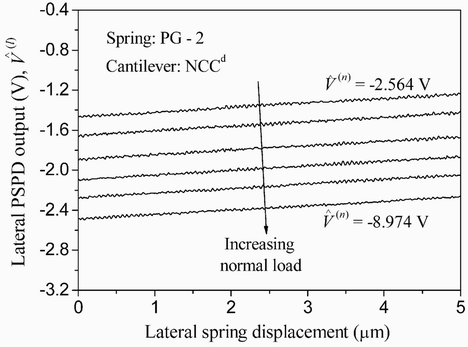

If everything is carried out correctly, you will get the data similar to those shown in Figure 9.

Figure 9. D-LFC data of the lateral PSPD output under incremental normal loads

According

to our experiences, this is the trickiest part of the calibration

process. Here are some tips, you may find them useful (or you can

contact me if you have some other weird problems):

- Use a larger scan size, i.e. larger spring displacement, as long as the probe doesn't slip relatively to the PG surface;

- Put

an acoustic cover if your AFM system has one; because the PG sheet is

floating in air, it is susceptible to the acoustic noise; and if your system has a poor vibration isolation, you can try the data averaging if necessary;

- If

you observe a significant oscillation in vertical direction, that's due

to the setting of feedback parameters; play with them you should be

able to find the recipe for your own AFM system. The reason for this is

that the feedback circuit could behave like an extra "electric spring"

to make the D-LFC and your probe at around resonant status;

- Use a reasonable

slow scan rate; this would reduce the effect of the eddy current and the

possible air perturbation, though our testing shows that the

calibration results are not sensitive to them.

Data Processing [top]

The data processing is summarized in Figure 8.

To simplify data processing, the AFM base displacement is approximated

as the lateral spring displacement. Then it is multiplied by the spring

constant  and converted to the lateral force , which is shown on the horizontal

axis at the top of Fig. 8. Now we have a data set relating

and converted to the lateral force , which is shown on the horizontal

axis at the top of Fig. 8. Now we have a data set relating  and and  for a fixed value of for a fixed value of  . Recalling the equation (1) in Background in a difference form, . Recalling the equation (1) in Background in a difference form,

(6) (6)

the inverse slop,  , of the data is the lateral force constant , of the data is the lateral force constant  . In addition, two response lines for two different . In addition, two response lines for two different  's should be parallel to each other as shown by a dashed line in the figure. The crosstalk lateral force constant 's should be parallel to each other as shown by a dashed line in the figure. The crosstalk lateral force constant  is given by is given by  . Thus, experimental measurements of the responses . Thus, experimental measurements of the responses  's with respect to the lateral force (or spring displacement) for two different 's with respect to the lateral force (or spring displacement) for two different  's can provide the values of both 's can provide the values of both  and and  via two linear fittings. via two linear fittings.

Up to here, you have gone through all the details of D-LFC. Hope you enjoy this scientific toy :)

If you have any questions or comments, please don't hesitate to contact us.

|