Distributed November 18, 2002

For Immediate Release

News Service Contact: Kristen Cole

Metal baseball bats outperformed wooden bats in Brown study

Metal bats consistently outperformed wooden bats in an analysis of 502 hits off 19 baseball players at the professional minor league, collegiate, and high school level. Researchers attributed the metal bats’ greater batted ball speeds to faster swings and greater elastic performance.

PROVIDENCE, R.I. — Metal baseball bats can significantly outperform wooden bats according to a recent study by a group of Brown University bioengineers, confirming a belief widely held by players and coaches.

The average speed of a hit off the fastest bat, a metal model, was 93.3 mph; the average off the slowest bat, a wooden model, was 86.1 mph. Only 2 percent of hits made with wooden bats exceeded 100 mph, while 37 percent of the hits with the fastest metal bat more than 100 mph, according to Joseph J. Crisco, associate professor of Orthopaedics at the Brown Medical School. However, researchers also found one metal bat performed similarly to wooden bats.

The findings were published in the October 2002 issue of Medicine and Science in Sports and Exercise. Although there is a general consensus that metal bats outperform wooden bats, few scientific studies have documented performance differences.

Batter up

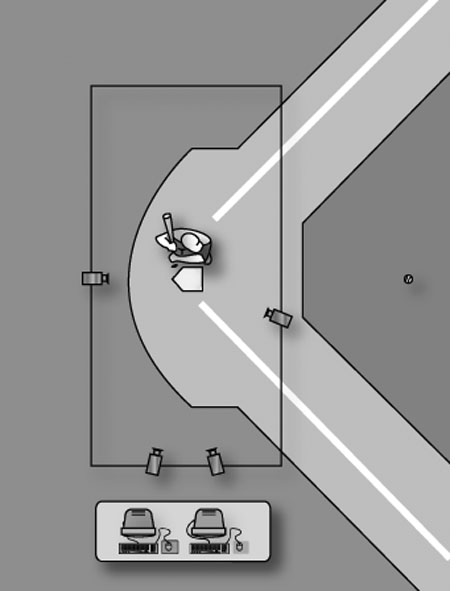

An aerial schematic shows the batting cage with cameras and data acquisition computers. Four infrared cameras were mounted on a scaffold around home plate. During the study, right-handed batters faced a pitching machine located 45 feet away.

In addition, the study confirmed the notion of a “sweet spot” associated with maximum ball speeds – those within the top 20 percent of the fastest hits from each bat model. The sweet spot was located approximately the same distance from the tip of wooden bats as it was from the tip of metal bats, according to Crisco.

Researchers concluded the metal bats produced faster batted ball speeds in part due to faster swing speeds, and, in part, to greater elastic properties found in nearly all of the metal bat models. In general, the lighter bats were swung faster and were associated with faster batted ball speeds.

Nineteen right-handed male baseball players at the level of professional minor league, collegiate and high school participated in the study. They used two wooden and five aluminum models from four manufacturers. Researchers measured batted ball speed, bat swing speed, bat impact location, and the elastic performance properties of the bats.

Each player faced 10 to 20 pitches from a pitching machine with each bat. Researchers surrounded home plate with scaffolding supporting four infrared-sensing cameras to track the three-dimensional trajectory of the bat before impact as well as the pitched and batted ball; the cameras sensed reflective tape affixed to the bats and the balls.

More than 1,000 pitches were recorded, of which about half were able to be analyzed. The others resulted in foul balls, pop-ups, missed pitches, or incomplete data.

The findings contribute to an ongoing dialogue about whether metal bats increase the chance of injury to a pitcher – something this study did not examine – and therefore should be regulated.

Currently high school and college players use aluminum and other metal alloy bats and wooden bats are used in major and minor league baseball. However that may change. A recent decision by the Massachusetts Interscholastic Athletic Association, which regulates high school play, requires wooden bats in the 2003 tournament.

Metal bats were introduced in the 1970s as a cost-saving alternative to wooden bats that were prone to break. A decade later, a general consensus had developed among players and coaches that metal bats could outperform wooden ones. In the late-80s, the National Collegiate Athletic Association implemented guidelines for weight and length of bats.

Crisco conducted the research with Richard M. Greenwald of the National Institute for Sports Science and Safety; Jeffrey D. Blume, assistant professor of research in community health at Brown; and Lorraine H. Penna, a member of the Class of 1998. The study was supported by the Sporting Goods Manufacturers Association (SGMA), University Orthopedics Inc., and the RIH Orthopaedic Foundation Inc.

######