Automatic Control

If the sampling theorem would be the single most important fact

you remember from EN123, then automatic control would be the most important

theme. Automatic control subsumes the ideas of feedback and feed-forward control;

negative and positive feedback, and particularly requires that the "plant"

being controlled exhibits some dynamics worth dealing with in the frequency

domain, likely by Laplace transform. On the other hand, the linear world of

Laplace transforms may be left behind confronting non-linear systems.

Examples of feed-forward control: audio

AGC (automatic gain control), mufflerless exhaust, fetal heart monitor...

0The varieties of feedback experience

As engineers we want to move beyond a hand-waving verbal account of feedback,

to a mathematical description which will allow us to model and predict various

actions of negative feedback controllers. This lecture introduces the context

of feedback and tells you about the virtues of feedback in any system. You'll

learn how feedback can stabilize, speed up and regulate a system. Part of what

you'll learn is terminology: feedback vs feedforward, negative vs positive feedback,

discrete vs continuous and linear vs nonlinear feedback.

Background: Recall

Laplace transforms from Circuits and Differential Equations courses.

Use Mathworks program SIMULINK to build

dynamic systems with feedback. A SIMULINK demo may be given for a nonlinear feedback

system. Simulink is like LabVIEW: An iconic language, with a wiring tool to make

connect icons.

%------------------------------------------

Feedback means sending a copy of an output signal

back to an input summation part of the system, where it can influence the system

components which helped form it in the first place. If this definition sounds

circular, it is! It may remind you of recursion in programming. The copy of

output sent as feedback may be attenuated or amplified; it may even be reversed

in sign. In any physical system the feedback path is inevitably associated with

some delay. The dynamics of that delay can create some of its most useful or

destabilizing effects. In the diagram below a summation unit adds external input

to output transformed through a feedback circuit. The effect of feedback may

be positive or negative at the summation point.

The summation point can be an op amp configured as a summation amplifier. The

forward pathway has two parts: The Plant is the apparatus itself--muscle, reactor

vessel, oven, motor, etc.--generally the Plant is not amenable to adjustment.

Compensation is where your design skills come in. Compensation will have gain

and possibly phase-shifting (filtering). In the feedback path is the SENSOR:

and it may translate a physical parameter such as temperature or air flow into

a voltage, so the SET point sees commensurable inputs.

Negative feedback is useful in various situations

where an output should be maintained at a desired level in spite of parameter

or load disturbances.

Automatic Control vs Homeostatics:

Automatic control is imagined to be

carried out by sensors that transduce physical data into voltage; control itself

is achieved by motors, heaters, pumps, and other electromechanical devices.

To account for sensing and control by biological tissue and organs, physiologists

(see Bio 80) use the term homeostatics. It implies that important physiological

parameters need to be kept in limited ranges, by means of negative feedback.

Examples are

Blood presssure (vessel dilation)

Blood sugar (insulin)

Potassium ions (actions in kidney)

Pupil diameter of the eye (light level)

Sense of balance (vestibular organ)

Temperature (metabolism)

Stretch reflex (golgi tendon organs)

Intracellular cyclic GMP (phosphodiesterase enzyme activity)

Closed loop gain calculation

Shown below are feed-forward and feedback configurations, with subtractive comparisons

at the summation units.

Now we develop the basic feedback equation, using algebra. The

compensation and plant have been combined into one forward path unit, G. Assume

a system output y(t) is intended to match a goal x(t), shown in

the figure below.

Without feedback y(t) = g(x(t)), where g is called gain and is a function-anything

from multiplication by a constant to a differential equation. With negative feedback

an error = x-f' is amplified by gain g until the negative feedback

reduces error to an acceptable level. The feedback signal is formed as the product

of y�f, where f is the feedback gain and f' is the feedback

signal presented to the summation amplifier on the left.

It's negative feedback because of the subtraction of f from goal

x.

Note that closed loop gain is lower than open loop gain. In fact

if f=1, closed loop gain is always less than 1! This reduction in gain had better

be good for something!

Virtues of negative feedback

1. Reduce sensitivity to internal parameter

changes

Suppose g = 100 in the system above. Then the close loop gain

is

Now suppose g changes by a factor of 2, to 200. The close loop gain is still

about 0.99. Negative feedback reduces sensitivity of the system to changes in

internal parameters. In this case the only internal parameter we have is open-loop

gain. What could make the system sensitive to gain changes? If the gain is too

low, less than 10 for example. In general, a high open loop gain is desired.

2. Reduce sensitivity to external

load changes

Let a variable load affect the output, as shown below:

Now

If L = 0 then the same G/(1+G) closed loop gain results. Even if L is not = 0, the

effect of load on the output is reduced by 1/(1+G) ! Thus negative feedback systems

have reduced sensitivity to external load changes. As an example of external load,

consider a beaker held up by the neuromuscular system of the arm; the aim is to

hold the beaker at a constant position in spite of liquid being poured in.

Example of plant and load dynamics: Suppose the

plant is a LP filter (leaky integrator)

Now suppose the load changes suddenly, at t=0, from 0 to 2: that would be

a step of magnitude 2:

and for t > 0 the output is close to 2/10, which would be the

(Load 2) / (Gain 10)

3. Increased speed of response

Now consider dynamics in the Plant. See the negative feedback system shown below.

Forward path and feedback are represented by Laplace transforms, so multiplication

of transfer functions can take the place of time-domain convolution integrals. Let

a "gain-of-one" first-order LP system.

[Review: What function of time

is this a transform of? What differential equation does the Laplace transform represent?

A leaky integrator, or first order LP filter.]

Let feedback be f = k, where k is attenuation: 0 < k < 1.

If F(s) = 1 then the open loop response of the system is Y(s) = In(s) � G(s).

If In(s)=1 (impulse function) then

a decaying exponential with time constant 1/a. The larger a is, the faster the system

decays. And decay to zero is what we want, when the input is an impulse. The impulse

is a brief disturbance, and we want the system to return to its zero state as soon

as possible. After t=0 input is zero, and we want y(t) to track the input. Now consider

the closed loop.

Substitute G(s) in the formula G/(1+G), which we can do because we

are in the frequency domain. If we were in the time domain, convolution would be

called for. At any rate, the formula simplifies to

which has inverse Laplace transform

Compared to the open loop form the time constant 1/(a+1) is smaller, so the system

decays to zero faster.

Suppose F>1 or GOL > 1 then

the time constant will be even smaller. Bottom line: Negative feedback can speed

up the response of a dynamic system.

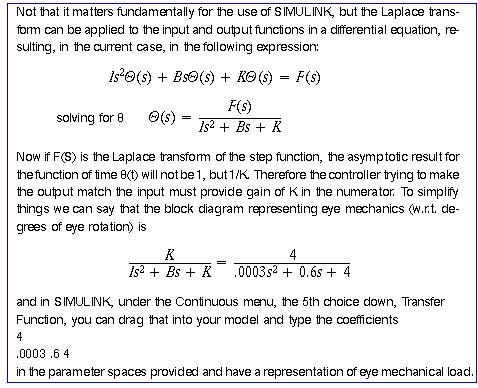

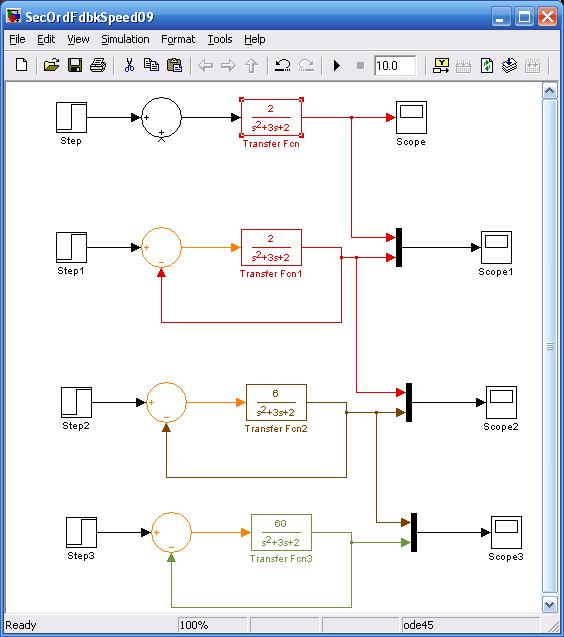

(2009) Negative feedback, second order

systems, increased speed of response and underdamped responses. Imagine

the "plant" is something like an eyeball, and has rotational inertia,

viscous drag, and torsional spring stiffness of the antagonist muscle, modelled

in Laplace transform...

which is a v. overdamped dynamic system.

Consider a barely-overdamped transfer function, started by the following sequence,

shown "live" in lecture in Simulink...

You will see that as the speed of response

increases the system becomes more underdamped, producing an undesirable oscillation

around the asymptotic value. Eventually compensation can artifically increase

damping and create speed increase without oscillation.

4. Stabilize a system

Now consider an unstable dynamic system:

Give the open loop block a Laplace transform with a negative time constant and set

feedback F = 0. The inverse Laplace transform is

The exponential is positive. The system is unstable. It's impulse response grows

exponentially. Now consider what happens if negative feedback is put in place. Let

F=1. Substituting in the basic formula we obtain

Let IN(s) be 1, for the input to be an impulse function. Now output is

A stable form with a decaying exponential. What's the time constant?

Bottom line here: Negative feedback can stabilize a system. Add

to the list of negative feedback virtues. Notice that in the dynamic examples given,

we haven't used large open loop gain, but certainly large open loop gain can amplify

the speeding-up and stabilizing effects

5. Inverse systems in feedback

Place the dynamic element in the feedback path, while maintaining a high open loop

gain A :

Applying the feedback formula

to this arrangement, while

letting IN(s) be 1, for the impulse input, we find,

If A*F(s) >> 1 then

So the element F(s) is turned

into its inverse: In a gyrator circuit a capacitor in a feedback loop "turns

into an inductor", for the sake of filter sharpness. In other cases we seek

the inverse of a system in order to "cancel" some effect or other.

Increasing first order LP time constant with positive feedback

Look at a dynamic system with positive feedback k less than 1:

Apply the feedback formula to find

OK, let's say k

< a. If

so, then a-k is a positive number smaller than a.

So the time constant of the system, 1/(a-k), is correspondingly larger

than 1/a.

Positive feedback can be used to "slow down" a leaky integrator.

Example: "Velocity

storage" in the VOR: lengthening the time constant of the vestibular apparatus,

from 5 sec to 20 sec. see

http://www.engin.brown.edu/courses/122JDD/Lcturs/vstopt05.html

where a positive feedback loop is embedded in an overall negative feedback loop

for visual tracking and fixation.

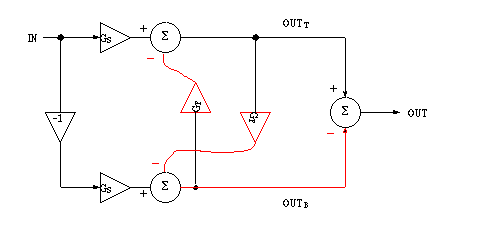

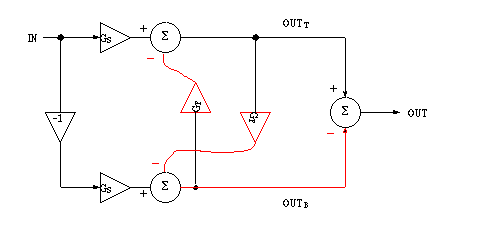

Push-Pull amplifier: Another example of two negatives

in a control loop creating positive feedback-- A push pull amplifier can accept

two inputs, sometimes out of phase with each other, such as vestibular nuclei

that are cross-coupled. Below is a diagram of a push pull system, with two internal

outputs subtracted for one external output. The gain equation is worked out:

Notice that if GF is 0.9 then the gain is 20*Gs.

Transport delay in feedback path, plus an inverter for the plant

= oscillator. For now consider the the effect of delay in the one-inverter-with-feedback:

OUT becomes IN almost instantly, in "rise time" σ but IN must wait

a longer transport time Δ before it starts to change to the new value of IN.

Assume &Delta > σ. The result is the following "timing diagram"

for input and output waveforms. Thinking about what causes what can send you around

in circles, so start by considering that the circuit has just been turned on, and

IN is zero. As soon as power is applied, OUT goes (with rise-time sigma) to HI,

but a change of IN to HI must wait for delay Delta to expire.

An oscillation, with period 2�(Delt+sig), results.

[If sig > Delt, then the metastable condition can last "a long time";

such may be the case with various IC inverters.]

(To be more careful in this analysis of feedback we must specify the thresholds

2H

and 2L

at which the inverter snaps from one binary value to another.

Assume for now that

OUT will snap up if IN < 1 volt = θL, and

OUT will snap down if IN > 4 volts = θH .

Delay in feedback The Laplace transform of pure delay is:

An example: The signal going up from a spindle to a motoneuron

in a feedback loop is not just slowed down by an integration process, it is absolutely

delayed by finite (and slow) conduction speed. In engineering terms such delay is

called transport delay. It's commonly seen is chemical engineering

systems where fluid to be measured (dissolved electrolyte, for example) is transported

down a pipe until it arrives at a sensor. How can we handle pure delay in terms

of Laplace transforms? The Laplace transform of pure delay f(t-t0) is exp(-s*t0)*F(s)

where t0 is the duration of the transport delay. The exponential can be approximated

by the Maclaurin series,

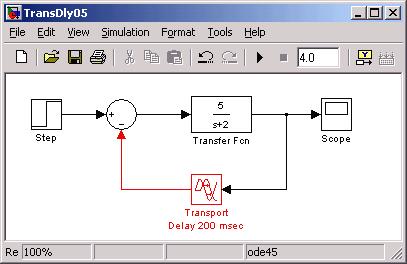

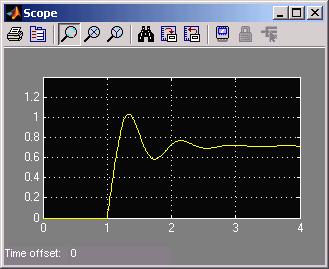

Without having to work out an analytical solution, we can demonstrate the effect

of transport delay with SIMULINK (an efficient way to simulate dynamic systems)

from Mathworks, up the road in Natick, MA.

where you see that a first order system now appears like a second order underdamped

response due to transport delay in the feedback path.

Proportional, integral, derivative compensation

Control engineers call it PID. So far we have considered mainly proportional

compensation, where the error signal is multiplied by some proportional factor,

KP. We will look briefly at the effects of PID compensation. For example, integral

feedback is capable of driving the error of a system to zero, not just to some small

value. Follow the development in Wolovich's book, pages 271-286.

PI controller: Proportional + Integral compensation looks like

which has the form (in EN122, eye movements) of the Oculomotor Nucleus compensation

before the transfer function representing eyeball mechanics.

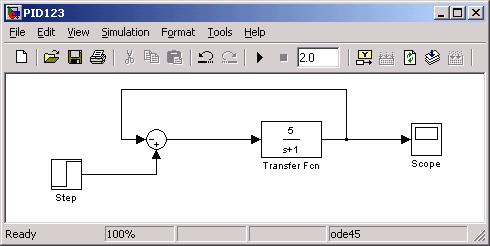

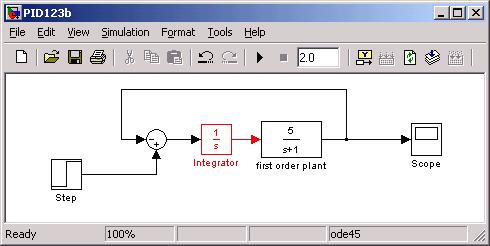

Example of Integral compensation driving error to zero. Start

with the Simulink model shown below, with a first order plant having a low frequency

open loop gain of 5:

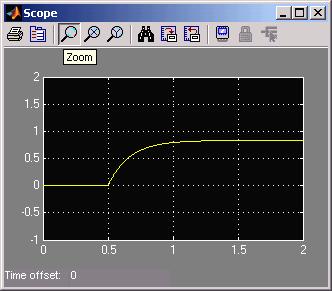

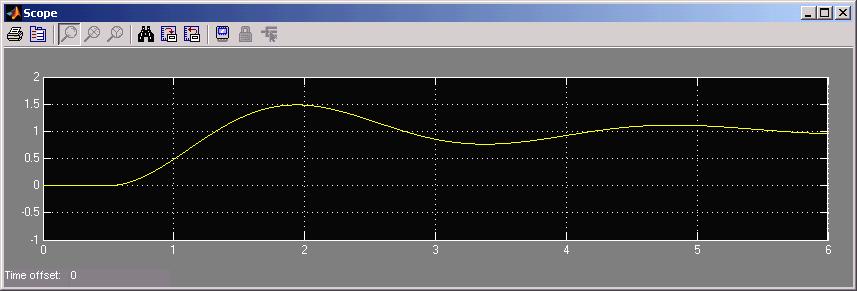

Below is the Scope output for a step input start at t = 0.5.

Notice the permanent error of 1/6 from the desired output of 1.00. G/(1+G) = 5/6.

Now add integral compensation:

We can start to work out what we expect analytically at the output: The close loop

transfer function is

The integral compensation has taken the system to 2nd order, and an underdamped

2nd order at that. Remembering that the Laplace transform of the step input is 1/s,

we see that output is

a partial fraction expansion that can be solved for the coefficients A0, A1, A2.

We will expect as a function of time a step and damped oscillation. See the Simulink

output below:

Which has the expected damped oscillation of period 2.88 seconds. Notice that the

asymptotic value is now 1.00. No error! Yes, there are oscillations leading up to

the approach to the exact answer: that would be expected of something converted

to an underdamped second order system.

Feb 2005: Numerical solution for PFE coefficients of the step

component of response: Use Matlab function residue to find coefficients

of PFE for proportional and integral compensation of example above:

>> help residue

>> Ai = [ 1 1 5 0 ] % coefficients

of integral control response

>> B = 5

>> [R,P,K] = residue(B,Ai)

with the result that the "residue"

or PFE coefficient of C/s is C = 1.0.

Since the inverse Laplace transform of C/s is C*1(t), where 1(t) is the step

response, then the steady-state response to integral control is perfect match

to a 1/s step input.

When we consider proportional

control then the closed-loop proportional output response to a step input is:

And the proportional coefficients

AP = [ 1 6 0 ]

calculating residues in Matlab:

>> [R,P,K] = residue(B,Ap)

with the result that now the "residue"

of C/s is C = 0.8333 = 5/6 and 1-5/6 = .16666 is the steady-state error of proportional

control.

Proportional-Derivative

compensation  is

more problematical: To quote from Wolovich (p.281): "In general, an ideal

derivative compensator is difficult to construct (exception: a tachometer).

Moreover, since its magnitude increases without bound as frequency increases,

an ideal differentiator produces undesirable amplification of any high frequency

noise that may be present in the loop." Practical derivative control needs

a leaky integrator to eliminate high frequency instability.

is

more problematical: To quote from Wolovich (p.281): "In general, an ideal

derivative compensator is difficult to construct (exception: a tachometer).

Moreover, since its magnitude increases without bound as frequency increases,

an ideal differentiator produces undesirable amplification of any high frequency

noise that may be present in the loop." Practical derivative control needs

a leaky integrator to eliminate high frequency instability.

---------------------------- --------------------------------

Bang Bang controller: Up to now we have considered the

error signal as a "floating point" number whose magnitude and sign are

used to tell the plant how to best to correct the error; the first-order attempt

by the plant is a proportional response. What if there is a region of error we don't

care about, and beyond the don't-care region we want the controller to work at a

constant (perhaps maximum) rate? Then we want a bang-bang controller.

When a bang-bang system senses a signal is out of range it

turns on the controller to a "maximum" setting until the signal comes

back in range, then it turns the controller off completely. The controller may

have 2 maximum settings, such as hot/cold, or CW/CCW. By "out of range"

we mean that there is a hysteresis range within which the output tolerated:

The narrower the range, the more frequently the controller will turn on and

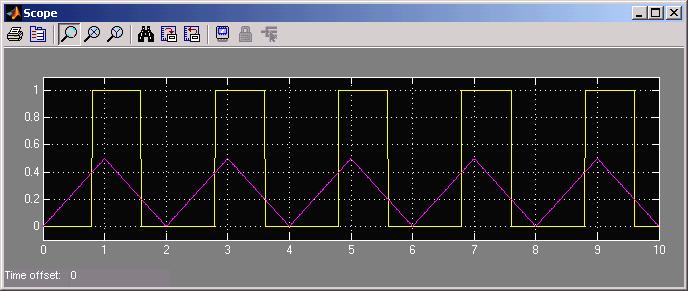

off (turning the furnace on and off for example). Below we show a Simulink model

for a bang-bang controller, and its output due to a triangle-wave input:

The red part on the left above generates the triangle wave shown below in purple.

In the diagram above it is necessary to convert from Boolean to floating point

(yellow boxes). The memory element in the controller is the Set-Reset Latch,

shown in orange.

The hysteresis thresholds for turning the controller on and off are 0.2 and

0.4. If the input is rising, it turns on the controller above 0.4, but doesn't

turn it off again until the input is less than 0.2.

The excitation table for a S-R latch is

| Set |

Reset |

Q |

| 0 |

0 |

no change |

| 0 |

1 |

0 |

| 1 |

0 |

1 |

| 1 |

1 |

NOT ALLOWED |

where the state SR = 00 is the memory state, whose output depends on previous input

timing.

See Daniels, Digital Design From Zero to One, chpt 5, John Wiley & Sons

(1996) for more details about flip flops and latches.

The Simulink example above is lacking two important features:

1. There is no feedback in the model!

2. There is no dynamics!

The model illustrates hysteresis by bang-bang control, that's all. .

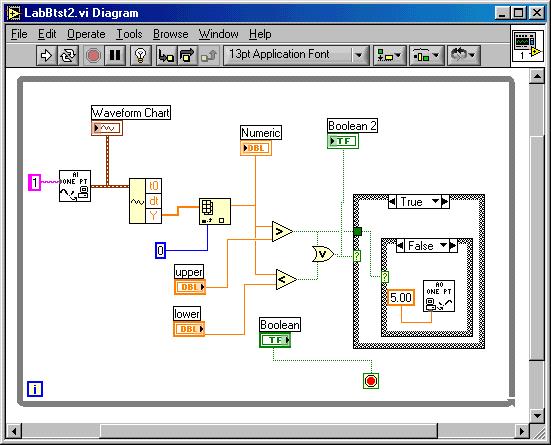

LabVIEW (EN123) can also support bang-bang controllers, but LabVIEW

does not have SR latches as such; it relies on logic for exiting from While

loops, as this example shows.

In the next example ( linked at bang-bang

heater) we provide dynamics from the thermal properties of a body being

heated, and close the feedback loop, with cool ambient temperature as a parametric

input to the plant.

Fuzzy Logic Controller. The interval of acceptable

output can be better described by a bell-shaped or triangle-shaped function,

and called a fuzzy set membership function. (more later... See Bart Kosko, Fuzzy

Engineering, P-H (1997): Part III, "Fuzzy Control and Chaos".)

To see fuzzy logic in action, with Simulink, go to the Fuzzy

Logic Toolbox documentation and find the water level control example: here

is the path--

Help:Fuzzy Logic Toolbox:Tutorial:Working with Simulink:An Example-Water Level

Control

Demo: Balancing a 1m PVC pipe on my palm: moving feet

not allowed; visual feedback: monocular: nondominant eye only; looking at hand

instead of pole; in strobe light, 10Hz.

Regulation of air flow (EN123 Lab)

Show OUT = BIAS + Reg(s) as output air flow.

(What is the nonlinear relationship between voltage and flow velocity?)

Reg(s) is the output of E(s*M(s) where E is the error, E = Set - F(s)OUT and M(s)

is the fan characteristic Set is the desired airflow OUT(s) goes to T(s) the tach

and perhaps gain or C(s), compensation. Gain may be needed in the "open loop"

We end up with an equation

(demonstrates regulation of Bias type noise...)

If you're using LabVIEW you want OUT to equal SET; IN-OUT is the error.

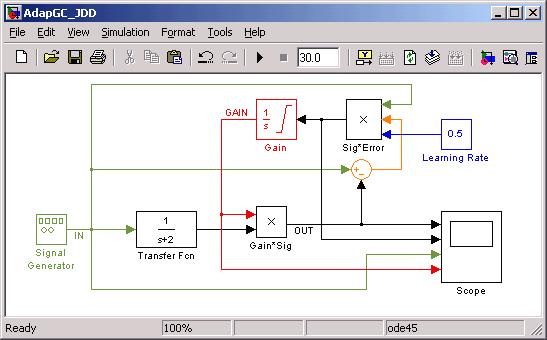

Adaptive gain control. (2006) There are really two ways to react to error

signals: One: What we have seen so far: let the increased error itself be the

input to the plant (negative feedback); or Two: Have the "unconditioned stimulus"

be the input and let the error control a process that changes the gain itself.

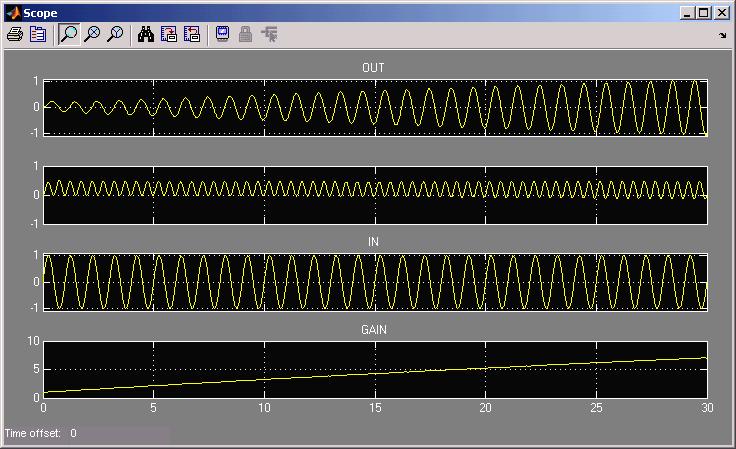

This second approach is called adaptive gain control and is the basis of adaptive

neural networks, a topic itself large enough for a one-semester course. Below

is a Simulink model of a 1-input adaptive gain controller, and the relevant outputs:

(EN122: needed for adaptive gain control of VOR)

See link to Notes on Gradient

Descent to see why three signals:

Learning Rate*Error*Stimulus, are multiplied together for Gain integrator input. Notice

that the change in gain is "permanent": if the input goes to zero, the integrator

retains its new value...long-term memory. More detail below:

The equations unfortunately do not boil down to something as straightforward as

OUT = G/(1+G)*IN, but are amenable to simulation, where weight W(t) is the output

of an integrator whose input is the product of the three factors shown.

Suggested Reading

W. A. Wolovich Automatic

Control Systems, Saunders (1993), "PID Compensation,"

pages 271-286.

Curtis D. Johnson, Process

Control Instrumentation Technology

7th Edition, Prentice-Hall (1998).

Other Reading

Clare D. McGillem & G.R. Cooper, chapter 5, �15, "Feedback systems,"

pages 270-283, in Continuous and Discrete Signal and System Analysis,

3rd Edition, Holt-Rinehart and Winston (1991).

V. S. Vaidhyanathan, Regulation

and Control Mechanisms in Biological Systems, Prentice-Hall (1993).

Oppenheim & Willsky, chapter 11 (first 2 �'s) pages 685-701

in Signals and Systems, Prentice-Hall (1983). O&W was the

EN157 book a few years ago.

Summary

* G-CL = G/(1+G) where G is open-loop gain

* G/(1+FG), where F is feedback gain.

If FG>>1 then an inverse system F-inv can be created at output

* Virtues of negative feedback

insensitivity to parameter or load changes

increased speed

improves stability

* Creating inverse systems

* Positive feedback gain-less-than-one to increase time constant

* Frequency response as a function of loop gain.

* Delay & stability & non-linear/time varying systems

* PID = proportional/derivative/differential compensation

& the problem of pure differentiation

* Bang-bang controllers

* Fuzzy logic controllers

* Adaptive gain control (neural networks)