Chapter 7

Stress-Strain

relations for linear elastic materials

You

are probably familiar with the behavior of a linear elastic material from

introductory materials courses.

7.1 Isotropic, linear elastic material behavior

If

you conduct a uniaxial tensile test on almost any material, and keep the stress

levels sufficiently low, you will observe the following behavior:

The specimen deforms reversibly: If you remove the loads, the solid returns to

its original shape.

The specimen deforms reversibly: If you remove the loads, the solid returns to

its original shape.

The strain in the specimen depends only on the

stress applied to it it doesn’t depend on the rate of loading, or

the history of loading.

The strain in the specimen depends only on the

stress applied to it it doesn’t depend on the rate of loading, or

the history of loading.

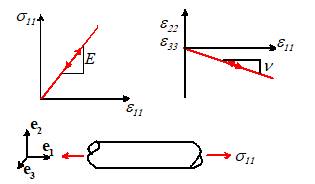

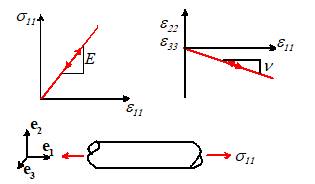

For most materials, the stress is a linear

function of strain, as shown in the picture above. Because the strains are small, this is true

whatever stress measure is adopted (Cauchy stress or nominal stress), and is

true whatever strain measure is adopted (Lagrange strain or infinitesimal

strain).

For most materials, the stress is a linear

function of strain, as shown in the picture above. Because the strains are small, this is true

whatever stress measure is adopted (Cauchy stress or nominal stress), and is

true whatever strain measure is adopted (Lagrange strain or infinitesimal

strain).

For most, but not all, materials, the material

has no characteristic orientation. Thus,

if you cut a tensile specimen out of a block of material, as shown in the

figure, the the stressstrain curve will

be independent of the orientation of the specimen relative to the block of material. Such materials are said to be isotropic.

For most, but not all, materials, the material

has no characteristic orientation. Thus,

if you cut a tensile specimen out of a block of material, as shown in the

figure, the the stressstrain curve will

be independent of the orientation of the specimen relative to the block of material. Such materials are said to be isotropic.

If you heat a specimen of the material,

increasing its temperature uniformly, it will generally change its shape

slightly. If the material is isotropic

(no preferred material orientation) and homogeneous, then the specimen will

simply increase in size, without shape change.

If you heat a specimen of the material,

increasing its temperature uniformly, it will generally change its shape

slightly. If the material is isotropic

(no preferred material orientation) and homogeneous, then the specimen will

simply increase in size, without shape change.

7.2 Stressstrain relations

for isotropic, linear elastic materials. Young’s Modulus, Poissons ratio and the

Thermal Expansion Coefficient.

Before writing down stressstrain relations,

we need to decide what strain and stress measures we want to use. Because the model only works for small shape

changes

Deformation is characterized using the

infinitesimal strain tensor defined in Section 4.6. This is convenient for calculations, but has

the disadvantage that linear elastic constitutive equations can

only be used if the solid experiences small rotations, as well as small shape

changes.

Deformation is characterized using the

infinitesimal strain tensor defined in Section 4.6. This is convenient for calculations, but has

the disadvantage that linear elastic constitutive equations can

only be used if the solid experiences small rotations, as well as small shape

changes.

All stress measures are taken to be

equal. We can use the Cauchy stress as the stress measure.

All stress measures are taken to be

equal. We can use the Cauchy stress as the stress measure.

You probably already know the stressstrain relations

for an isotropic, linear elastic solid.

They are repeated below for convenience.

Here, E and are Young’s modulus and Poisson’s ratio, is the coefficient of thermal expansion, and is the increase in temperature of the

solid. The remaining relations can be

deduced from the fact that both and are symmetric.

The inverse relationship can be expressed as

HEALTH

WARNING: Note the factor of 2 in the strain vector. Most texts, and most FEM codes use this

factor of two, but not all. In addition,

shear strains and stresses are often listed in a different order in the strain

and stress vectors. For isotropic

materials this makes no difference, but you need to be careful when listing

material constants for anisotropic materials (see below).

We

can write this expression in a much more convenient form using index notation. Verify for yourself that the matrix

expression above is equivalent to

The inverse

relation is

The stress-strain relations are often expressed using the elastic modulus tensor or the elastic

compliance tensor as

In terms

of elastic constants, and are

7.3 Reduced stress-strain equations for plane

deformation of isotropic solids

For plane strain or

plane stress deformations, some

strain or stress components are always zero (by definition) so the

stress-strain laws can be simplified.

For a

plane strain deformation . The stress strain laws are therefore

For a

plane strain deformation . The stress strain laws are therefore

In index

notation

where Greek

subscripts can have values 1 or 2.

For a

plane stress deformation

For a

plane stress deformation

7.4 Representative values for density, and elastic constants of isotropic

solids

Most

of the data in the table below were taken from the excellent introductory text

`Engineering Materials,’ by M.F. Ashby and D.R.H. Jones, Pergamon Press. The remainder are from random web pages…

Note the units values of E

are given in ;

the G stands for Giga, and is short for . The units for density are in - that’s Mega grams. One mega gram is 1000 kg.

|

Material

|

Mass density

|

Youngs Modulus

|

Poisson Ratio

|

Expansion coeft

|

|

Tungsten Carbide

|

14 17

|

450650

|

0.22

|

|

|

Silicon Carbide

|

2.5 3.2

|

450

|

0.22

|

|

|

Tungsten

|

13.4

|

410

|

0.30

|

|

|

Alumina

|

3.9

|

390

|

0.25

|

|

|

Titanium Carbide

|

4.9

|

380

|

0.19

|

|

|

Silicon Nitride

|

3.2

|

320 - 270

|

0.22

|

|

|

Nickel

|

8.9

|

215

|

0.31

|

|

|

CFRP

|

1.5-1.6

|

70 200

|

0.20

|

|

|

Iron

|

7.9

|

196

|

0.30

|

|

|

Low alloy steels

|

7.8

|

200 - 210

|

0.30

|

|

|

Stainless steel

|

7.5-7.7

|

190 - 200

|

0.30

|

|

|

Mild steel

|

7.8

|

196

|

0.30

|

|

|

Copper

|

8.9

|

124

|

0.34

|

|

|

Titanium

|

4.5

|

116

|

0.30

|

|

|

Silicon

|

2.5-3.2

|

107

|

0.22

|

|

|

Silica glass

|

2.6

|

94

|

0.16

|

|

|

Aluminum & alloys

|

2.6-2.9

|

69-79

|

0.35

|

|

|

Concrete

|

2.4-2.5

|

45-50

|

0.3

|

|

|

GFRP

|

1.4-2.2

|

7-45

|

|

|

|

Wood, parallel grain

|

0.4-0.8

|

9-16

|

0.2

|

|

|

Polyimides

|

1.4

|

3-5

|

0.1-0.45

|

|

|

Nylon

|

1.1 1.2

|

2 4

|

0.25

|

|

|

PMMA

|

1.2

|

3.4

|

0.35-0.4

|

|

|

Polycarbonate

|

1.2 1.3

|

2.6

|

0.36

|

|

|

Natural Rubbers

|

0.83-0.91

|

0.01-0.1

|

0.49

|

|

|

PVC

|

1.3-1.6

|

0.003-0.01

|

0.41

|

|

7.5

Other Elastic Constants bulk, shear and Lame modulus.

Young’s modulus and Poisson’s ratio are the most common

properties used to characterize elastic solids, but other measures are also

used. For example, we define the shear modulus, bulk

modulus and Lame modulus of an

elastic solid as follows:

A nice table relating

all the possible combinations of moduli to all other possible combinations is

given below. Enjoy!

|

|

Lame

Modulus

|

Shear

Modulus

|

Young’s

Modulus

|

Poisson’s

Ratio

|

Bulk

Modulus

|

|

|

|

|

|

|

|

|

|

|

Irrational

|

|

Irrational

|

Irrational

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.6 Physical Interpretation of

elastic constants for isotropic solids

It is important to have a feel for the physical significance

of the two elastic constants E and .

Young’s

modulus E is the slope of the stressstrain curve in

uniaxial tension. It has dimensions of

stress ( ) and is usually large for steel, .

You can think of E as a measure of

the stiffness of the solid. The larger the value of E, the stiffer the solid. For

a stable material, E>0.

Young’s

modulus E is the slope of the stressstrain curve in

uniaxial tension. It has dimensions of

stress ( ) and is usually large for steel, .

You can think of E as a measure of

the stiffness of the solid. The larger the value of E, the stiffer the solid. For

a stable material, E>0.

Poisson’s ratio

Poisson’s ratio  is the ratio of lateral

to longitudinal strain in uniaxial tensile stress. It is dimensionless and

typically ranges from 0.20.49, and is

around 0.3 for most metals. For a stable

material, .

It is a measure of the compressibility of the solid. If ,

the solid is incompressible its volume remains constant, no matter how it

is deformed. If ,

then stretching a specimen causes no lateral contraction. Some bizarre materials have -- if

you stretch a round bar of such a material, the bar increases in diameter!!

is the ratio of lateral

to longitudinal strain in uniaxial tensile stress. It is dimensionless and

typically ranges from 0.20.49, and is

around 0.3 for most metals. For a stable

material, .

It is a measure of the compressibility of the solid. If ,

the solid is incompressible its volume remains constant, no matter how it

is deformed. If ,

then stretching a specimen causes no lateral contraction. Some bizarre materials have -- if

you stretch a round bar of such a material, the bar increases in diameter!!

Thermal

expansion coefficient quantifies

the change in volume of a material if it is heated in the absence of

stress. It has dimensions of (degrees

Kelvin)-1 and is usually very small.

For steel,

Thermal

expansion coefficient quantifies

the change in volume of a material if it is heated in the absence of

stress. It has dimensions of (degrees

Kelvin)-1 and is usually very small.

For steel,

The bulk

modulus quantifies the resistance of the solid to volume changes. It has a large value (usually bigger than E).

The bulk

modulus quantifies the resistance of the solid to volume changes. It has a large value (usually bigger than E).

The shear

modulus quantifies its resistance to volume preserving shear

deformations. Its value is usually

somewhat smaller than E.

The shear

modulus quantifies its resistance to volume preserving shear

deformations. Its value is usually

somewhat smaller than E.

7.7 Strain Energy Density for Isotropic Solids

Note the following

observations

If you

deform a block of material, you do work on it (or, in some cases, it may do

work on you…)

If you

deform a block of material, you do work on it (or, in some cases, it may do

work on you…)

In an

elastic material, the work done during loading is stored as recoverable strain

energy in the solid. If you unload the

material, the specimen does work on you, and when it reaches its initial

configuration you come out even.

In an

elastic material, the work done during loading is stored as recoverable strain

energy in the solid. If you unload the

material, the specimen does work on you, and when it reaches its initial

configuration you come out even.

The work

done to deform a specimen depends only on the state of strain at the end of the

test. It is independent of the history

of loading.

The work

done to deform a specimen depends only on the state of strain at the end of the

test. It is independent of the history

of loading.

Based

on these observations, we define the strain

energy density of a solid as the work done per unit volume to deform a

material from a stress free reference state to a loaded state.

To

write down an expression for the strain energy density, it is convenient to

separate the strain into two parts

where, for an isotropic

solid,

represents the strain due

to thermal expansion (known as thermal strain), and

is the strain due to

mechanical loading (known as elastic strain).

Work

is done on the specimen only during mechanical loading. It is straightforward to show that the strain

energy density is

You can also re-write this

as

Observe that

![]() The specimen deforms reversibly: If you remove the loads, the solid returns to

its original shape.

The specimen deforms reversibly: If you remove the loads, the solid returns to

its original shape.![]() The strain in the specimen depends only on the

stress applied to it it doesn’t depend on the rate of loading, or

the history of loading.

The strain in the specimen depends only on the

stress applied to it it doesn’t depend on the rate of loading, or

the history of loading.

![]() For most materials, the stress is a linear

function of strain, as shown in the picture above. Because the strains are small, this is true

whatever stress measure is adopted (Cauchy stress or nominal stress), and is

true whatever strain measure is adopted (Lagrange strain or infinitesimal

strain).

For most materials, the stress is a linear

function of strain, as shown in the picture above. Because the strains are small, this is true

whatever stress measure is adopted (Cauchy stress or nominal stress), and is

true whatever strain measure is adopted (Lagrange strain or infinitesimal

strain). ![]() For most, but not all, materials, the material

has no characteristic orientation. Thus,

if you cut a tensile specimen out of a block of material, as shown in the

figure, the the stressstrain curve will

be independent of the orientation of the specimen relative to the block of material. Such materials are said to be isotropic.

For most, but not all, materials, the material

has no characteristic orientation. Thus,

if you cut a tensile specimen out of a block of material, as shown in the

figure, the the stressstrain curve will

be independent of the orientation of the specimen relative to the block of material. Such materials are said to be isotropic.![]() If you heat a specimen of the material,

increasing its temperature uniformly, it will generally change its shape

slightly. If the material is isotropic

(no preferred material orientation) and homogeneous, then the specimen will

simply increase in size, without shape change.

If you heat a specimen of the material,

increasing its temperature uniformly, it will generally change its shape

slightly. If the material is isotropic

(no preferred material orientation) and homogeneous, then the specimen will

simply increase in size, without shape change. ![]() Deformation is characterized using the

infinitesimal strain tensor defined in Section 4.6. This is convenient for calculations, but has

the disadvantage that linear elastic constitutive equations can

only be used if the solid experiences small rotations, as well as small shape

changes.

Deformation is characterized using the

infinitesimal strain tensor defined in Section 4.6. This is convenient for calculations, but has

the disadvantage that linear elastic constitutive equations can

only be used if the solid experiences small rotations, as well as small shape

changes. ![]() All stress measures are taken to be

equal. We can use the Cauchy stress as the stress measure.

All stress measures are taken to be

equal. We can use the Cauchy stress as the stress measure.![]() For a

plane strain deformation . The stress strain laws are therefore

For a

plane strain deformation . The stress strain laws are therefore![]() For a

plane stress deformation

For a

plane stress deformation ![]() Young’s

modulus E is the slope of the stressstrain curve in

uniaxial tension. It has dimensions of

stress ( ) and is usually large for steel, .

You can think of E as a measure of

the stiffness of the solid. The larger the value of E, the stiffer the solid. For

a stable material, E>0.

Young’s

modulus E is the slope of the stressstrain curve in

uniaxial tension. It has dimensions of

stress ( ) and is usually large for steel, .

You can think of E as a measure of

the stiffness of the solid. The larger the value of E, the stiffer the solid. For

a stable material, E>0.![]() Poisson’s ratio

Poisson’s ratio ![]() is the ratio of lateral

to longitudinal strain in uniaxial tensile stress. It is dimensionless and

typically ranges from 0.20.49, and is

around 0.3 for most metals. For a stable

material, .

It is a measure of the compressibility of the solid. If ,

the solid is incompressible its volume remains constant, no matter how it

is deformed. If ,

then stretching a specimen causes no lateral contraction. Some bizarre materials have -- if

you stretch a round bar of such a material, the bar increases in diameter!!

is the ratio of lateral

to longitudinal strain in uniaxial tensile stress. It is dimensionless and

typically ranges from 0.20.49, and is

around 0.3 for most metals. For a stable

material, .

It is a measure of the compressibility of the solid. If ,

the solid is incompressible its volume remains constant, no matter how it

is deformed. If ,

then stretching a specimen causes no lateral contraction. Some bizarre materials have -- if

you stretch a round bar of such a material, the bar increases in diameter!! Thermal

expansion coefficient quantifies

the change in volume of a material if it is heated in the absence of

stress. It has dimensions of (degrees

Kelvin)-1 and is usually very small.

For steel,

Thermal

expansion coefficient quantifies

the change in volume of a material if it is heated in the absence of

stress. It has dimensions of (degrees

Kelvin)-1 and is usually very small.

For steel, ![]() The bulk

modulus quantifies the resistance of the solid to volume changes. It has a large value (usually bigger than E).

The bulk

modulus quantifies the resistance of the solid to volume changes. It has a large value (usually bigger than E).![]() The shear

modulus quantifies its resistance to volume preserving shear

deformations. Its value is usually

somewhat smaller than E.

The shear

modulus quantifies its resistance to volume preserving shear

deformations. Its value is usually

somewhat smaller than E. ![]() If you

deform a block of material, you do work on it (or, in some cases, it may do

work on you…)

If you

deform a block of material, you do work on it (or, in some cases, it may do

work on you…) ![]() In an

elastic material, the work done during loading is stored as recoverable strain

energy in the solid. If you unload the

material, the specimen does work on you, and when it reaches its initial

configuration you come out even.

In an

elastic material, the work done during loading is stored as recoverable strain

energy in the solid. If you unload the

material, the specimen does work on you, and when it reaches its initial

configuration you come out even.![]() The work

done to deform a specimen depends only on the state of strain at the end of the

test. It is independent of the history

of loading.

The work

done to deform a specimen depends only on the state of strain at the end of the

test. It is independent of the history

of loading.