Chapter 10

Implementing the Finite Element Method

for Linear Elasticity

The

goal of this chapter is to provide some insight into the theory and algorithms

that are coded in a finite element program.

Here, we will implement only the simplest possible finite element code:

specifically, we will develop a finite element method to solve a 2D (plane

stress or plane strain) static boundary value problem in linear elasticity, as

shown in the picture.

We assume that we are

given:

1.

The shape of the

solid in its unloaded condition

2. Boundary conditions, specifying displacements on a portion or tractions on a portion of the boundary of R

To

simplify the problem, we will make the following assumptions

The solid is an isotropic, linear elastic

solid with Young’s modulus E and

Poisson’s ratio ;

The solid is an isotropic, linear elastic

solid with Young’s modulus E and

Poisson’s ratio ;

Plane

strain or plane stress deformation;

Plane

strain or plane stress deformation;

The solid is at constant temperature (no

thermal strains);

The solid is at constant temperature (no

thermal strains);

We will

neglect body forces.

We will

neglect body forces.

We

then wish to find a displacement field satisfying the usual field equations and

boundary conditions (see Sect 5.1.1).

The procedure is based on the principle of minimum potential energy

discussed in Section 5.7. There are four

steps:

- A finite element mesh

is constructed to interpolate the displacement field

- The strain energy in

each element is calculated in terms of the displacements of each node;

- The potential energy

of tractions acting on the solid’s boundary is added

- The displacement field

is calculated by minimizing the potential energy.

These steps are discussed in

more detail in the sections below.

10.1 The finite element mesh

and element connectivity

10.1 The finite element mesh

and element connectivity

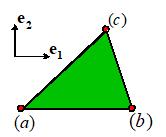

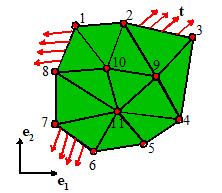

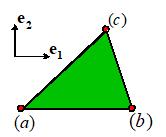

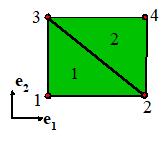

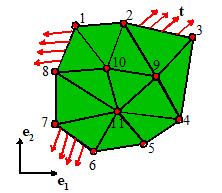

For

simplicity, we will assume that the elements are 3 noded triangles, as shown in

the picture. The nodes are numbered

1,2,3…N, while the elements are

numbered 1,2…L. Element numbers are shown in parentheses.

The position of the ath node is specified by its coordinates

The

element connectivity specifies the

node numbers attached to each element.

For example, in the picture the connectivity for element 1 is (10,9,2);

for element 2 it is (10,2,1), etc.

10.2 The global displacement vector

We

will approximate the displacement field by interpolating between values at the

nodes, as follows. Let denote the unknown displacement vector at

nodes . In a finite element code, the displacements

for a plane stress or plane strain problem are normally stored as a column

vector like the one shown below:

The

unknown displacement components will be determined by minimizing the potential

energy of the solid.

10.3 Element interpolation functions

To

calculate the potential energy, we need to be able to compute the displacements

within each element. This is done by

interpolation. Consider a triangular

element, with nodes a, b, c at its

corners. Let denote the coordinates of the corners. Define the element interpolation functions

(also known as shape functions) as

follows

These shape functions are

constructed so that

They vary

linearly with position within the element

They vary

linearly with position within the element

Each shape

function has a value of one at one of the nodes, and is zero at the other two.

Each shape

function has a value of one at one of the nodes, and is zero at the other two.

We then write

One

can readily verify that this expression gives the correct values for at each corner of the triangle.

Of course, the shape functions

given are valid only for 3 noded triangular elements other elements have more complicated

interpolation functions.

10.4 Element strains, stresses and

strain energy density

We

can now compute the strain distribution within the element and hence determine

the strain energy density. Since we are solving a plane strain problem, the

only nonzero strains are . It is convenient to express the results in

matrix form, as follows

The

factor of 2 multiplying the shear strains in the strain vector has been

introduced for convenience. Note that,

for linear triangular elements, the matrix of shape function derivatives is constant. It depends only on the coordinates of the

corners of the element, and does not vary with position within the

element. This is not the case for most

elements.

Now,

we can compute the strain energy density within the element. Begin by computing the stresses within the

element. For plane strain deformation, have

that

For plane stress, the

result is

Recall

(see Sect 3.1.7) that the strain energy density is related to the stresses and

strains by . This can be written in matrix form as

where

Now, express these results

in terms of the nodal displacements for the element

We

can now compute the total strain energy stored within the element. Because is constant, we merely need to multiply the

strain energy density by the area of the element, which can be computed from

the coordinates of its corners as follows

Hence, the total strain

energy of the element is

10.5 The element stiffness matrix

The strain energy can be

simplified by defining the element

stiffness matrix

so that

Observe

that, because the material property matrix is symmetric, the element stiffness matrix is also symmetric. To see this, note that

10.6 The Global stiffness matrix

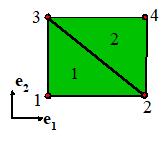

The total strain energy of the solid may be computed

by adding together the strain energy

of each element:

The total strain energy of the solid may be computed

by adding together the strain energy

of each element:

It

is more convenient to express W in

terms of the vector  which contains all the

nodal displacements, rather than using for each element to describe the

displacements. For example, the strain

energy for the simple 2 element mesh shown is

which contains all the

nodal displacements, rather than using for each element to describe the

displacements. For example, the strain

energy for the simple 2 element mesh shown is

If we

wanted to, we could add the missing terms to each element displacement vector:

We can now collect together corresponding terms in the two

element stiffness matrices to express this as

We can therefore write

where

is known as the Global stiffness matrix. It

is the sum of all the element stiffness matrices.

Because the element stiffness matrix is

symmetric, the global stiffness matrix must also be symmetric.

To

assemble the global stiffness matrix for a plane strain or plane stress mesh

with N nodes, we use the following

procedure.

1. Note that for nodes, there will be unknown displacement components (2 at each

node). Therefore, we start by setting up

storage for a global stiffness matrix, and set each term in

the matrix to zero.

2.

Next, begin a

loop over the elements.

3.

For the current

element, assemble the element stiffness matrix

4. Add the element stiffness matrix to the global

stiffness matrix, using the following procedure. Let a,

b, c denote the numbers of the nodes on the 3 corners of the element. Let for i=1…6,

j=1…6 denote the terms in the the

element stiffness matrix. Let for n=1…2N,

m=1…2N denote the terms in the global stiffness matrix. Then,

Here,

the symbol += means that the term on the left is incremented by the term on the

right, following standard C syntax.

5.

Proceed to the next element.

10.7 Boundary loading

We have now found a way to compute the strain energy

for a finite element

mesh. Next, we need to compute the

boundary term in the potential energy.

We have now found a way to compute the strain energy

for a finite element

mesh. Next, we need to compute the

boundary term in the potential energy.

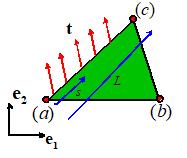

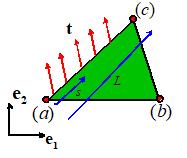

Boundary loading will be

specified as follows:

1.

The element on which the loading acts

2.

The face of the element which is loaded

3. The traction vector t (force per unit area) that acts on the face of the element. The traction is assumed to be constant on the

face of any one element.

Now,

we compute the contribution to the potential energy due to the traction acting

on the face of one element.

For the element shown, the contribution to the potential

energy would be

Recall that the displacements vary

linearly within a 3 noded triangle.

Therefore, we can write

Recall that the displacements vary

linearly within a 3 noded triangle.

Therefore, we can write

So, since

the tractions are uniform

Abbreviate

this as

10.8 Global force vector

The

total contribution to the potential energy due to boundary loading on all

element faces is

It is more convenient to

express this in terms of the global displacement vector

where  is the global residual

force vector.

is the global residual

force vector.

The global residual force

vector for a mesh with N nodes is

assembled as follows.

1. The residual force vector has length 2N (2 entries per node). Reserve storage for a vector of length 2N and initialize to zero

2.

Loop over

elements

3. Determine which face of the element is loaded. Let a,

b denote the node numbers attached to this face. Determine the residual force vector for the

element face. Let ,

i=1…4 denote the terms in the element

face residual vector. Let ,

n=1…2N denote the terms in the global

residual force vector. Then

10.9 Minimizing the Potential Energy

We have set up the

following expression for the potential energy of a finite element mesh

Now, minimize V

where we have noted that

Simplify this by noting

that is symmetric

This

is a system of 2N simultaneous linear

equations for the 2N unknown nodal

displacements. Standard computational

techniques such as Gaussian elimination, Cholesky factorization or conjugate

gradient methods may be used to solve the system of equations.

10.10 Eliminating prescribed displacements

So

far, we have seen how to calculate displacements in a finite element mesh which

is subjected to prescribed loading. What

if displacements are prescribed instead?

If

this is the case, the stiffness matrix and residual are first assembled exactly

as described in the preceding section.

They are then modified to enforce the constraint. The procedure is best illustrated using an

example. Suppose that the finite element equations after assembly have the form

To

prescribe displacements for any node, we simply replace the equation for the

appropriate degrees of freedom with the constraint. For example, to force ,

we could modify the finite element equations to

Thus, the equation for has been replaced with the constraint .

This

procedure works, but has the disadvantage that the modified stiffness matrix is

no longer symmetric. It is preferable to

modify the stiffness and residual further, to retain symmetry. To do so, we eliminate the constrained

degrees of freedom from all rows of the stiffness matrix. This is best

illustrated by example. Suppose our

modified stiffness matrix has the form

Now,

we wish to set each entry in the second column (apart from the diagonal) to

zero, so that the stiffness is symmetric.

Recall that we can add and subtract equations in the system from one

another without affecting the solution.

Therefore, to symmetrize the stiffness matrix in our example, we can

subtract appropriate multiples of the second row so as to set each entry in the

second column to zero.

10.11 Solution

The

result of Sections 10.1-10.10 is a set of simultaneous linear equations of the

form

These

can be solved for the unknown displacements using standard techniques (e.g. Gaussian

elimination or iterative techniques). An

important feature of the FEM equations is that the stiffness matrix is sparse that is to say, only a small number of entries

in the matrix are non-zero.

Consequently, special schemes are used to store and factor the

equations, which avoid having to store large numbers of zeros.

10.12

Post-processing

Once

the displacements have been computed, the strain in each element can be

computed, and so the stress distribution can be deduced. The procedure is as follows

1. For the element of interest, extract the displacement

of each node from the global displacement vector

2. Calculate the strains using the procedure in 7.2.4

3. The stresses can then be determined from the

stress-strain equations

where

is defined in 7.2.4.

10.13 Example FEA code

A

simple MATLAB implementation of the procedure is provided in the file

FEM_conststrain_m.

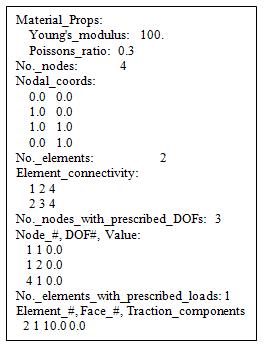

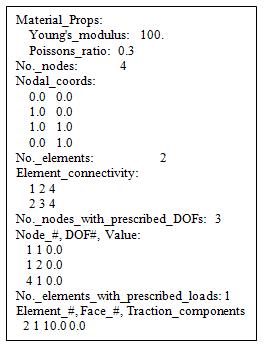

The code reads an input file. A very simple input file (with just two

elements) can be found in FEM_conststrain_input.txt. A second data file

The code reads an input file. A very simple input file (with just two

elements) can be found in FEM_conststrain_input.txt. A second data file

The

data file solves the problem illustrated in the picture. A rectangular block with Young’s modulus 100

and Poisson’s ratio 0.3 is meshed with two elements. Node 1 is pinned; node 4 is constrained

against horizontal motion, and the right hand face of element 2 is subjected to

a constant horizontal traction with magnitude 10.

The input file is shown below it should be mostly self-explanatory.

Note

that

1. Nodes are numbered sequentially thus node (1) has coordinates (0,0); node (2)

has coordinates (1,0), etc.

2. The element connectivity specifies the node numbers

attached to each element, using a counterclockwise numbering convention. It doesn’t matter which node you use for the

first one, as long as all the others are ordered in a counterclockwise sense

around the element. For example, you could use (2,4,1) instead of (1,2,4) for

the connectivity of the first element.

3. To fix motion of a node, you need to enter the node

number, the degree of freedom that is being constrained, (1 for horizontal, 2 for vertical), and a

value for the prescribed displacement.

4. To specify tractions acting on an element face, you

need to enter (a) the element number; (b) the face number of the element, and

(c,d) the horizontal and vertical components of traction acting on the

face. The face numbering scheme is determined

by the element connectivity, as follows.

Face (1) has the first and second nodes as end points; face (2) has the

second and third nodes; and face (3) has the third and first nodes as end

points. Since connectivity for element

(2) was entered as (2,3,4), face 1 of this element has nodes numbered 2 and 3;

face 2 connects nodes numbered 3 and 4, while face 3 connects nodes numbered 4

and 1.

and enter a

name for the output file.

and enter a

name for the output file.

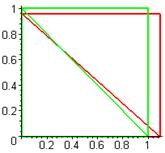

1. Return to the top of the file, and press <enter>

to execute each MAPLE block. If all goes well, you should see that, after

reading the input data, MAPLE plots the mesh (just as a check).

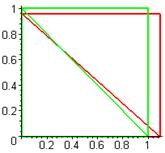

2. If you continue to the end, you should see a plot of

the displaced mesh (red) superimposed on the original mesh (green), as shown on

the right.

3. Finally, open the output file. It should contain the results shown below

![]() The solid is an isotropic, linear elastic

solid with Young’s modulus E and

Poisson’s ratio ;

The solid is an isotropic, linear elastic

solid with Young’s modulus E and

Poisson’s ratio ;![]() Plane

strain or plane stress deformation;

Plane

strain or plane stress deformation;![]() The solid is at constant temperature (no

thermal strains);

The solid is at constant temperature (no

thermal strains);![]() We will

neglect body forces.

We will

neglect body forces. 10.1 The finite element mesh

and element connectivity

10.1 The finite element mesh

and element connectivity

![]() They vary

linearly with position within the element

They vary

linearly with position within the element![]() Each shape

function has a value of one at one of the nodes, and is zero at the other two.

Each shape

function has a value of one at one of the nodes, and is zero at the other two. The total strain energy of the solid may be computed

by adding together the strain energy

of each element:

The total strain energy of the solid may be computed

by adding together the strain energy

of each element:![]() which contains all the

nodal displacements, rather than using for each element to describe the

displacements. For example, the strain

energy for the simple 2 element mesh shown is

which contains all the

nodal displacements, rather than using for each element to describe the

displacements. For example, the strain

energy for the simple 2 element mesh shown is We have now found a way to compute the strain energy

for a finite element

mesh. Next, we need to compute the

boundary term in the potential energy.

We have now found a way to compute the strain energy

for a finite element

mesh. Next, we need to compute the

boundary term in the potential energy. Recall that the displacements vary

linearly within a 3 noded triangle.

Therefore, we can write

Recall that the displacements vary

linearly within a 3 noded triangle.

Therefore, we can write![]() is the global residual

force vector.

is the global residual

force vector.

The code reads an input file. A very simple input file (with just two

elements) can be found in FEM_conststrain_input.txt. A second data file

The code reads an input file. A very simple input file (with just two

elements) can be found in FEM_conststrain_input.txt. A second data file  and enter a

name for the output file.

and enter a

name for the output file.