Chapter 2

Introduction to Finite Element Analysis

in Solid Mechanics

Most practical design calculations involve components

with a complicated three-dimensional geometry, and may also need to account for

inherently nonlinear phenomena such as contact, large shape changes, or

nonlinear material behavior. These

problems can only be solved using computer simulations. The finite element method is by far the most widely

used and versatile technique for simulating deformable solids. This chapter gives a brief overview of the

finite element method, with a view to providing the background needed to run

simple simulations using a commercial finite element program. More advanced analysis requires a deeper

understanding of the theory and implementation of finite element codes, which

will be addressed in the next chapter.

HEALTH

WARNING: It is deceptively easy to

use commercial finite element software: most programs come with a nice

user-interface that allows you to define the geometry of the solid, choose a material

model, generate a finite element mesh and apply loads to the solid with a few

mouse clicks. If all goes well, the

program will magically turn out animations showing the deformation; contours

showing stress distributions; and much more besides. It is all too easy, however, to produce

meaningless results, by attempting to solve a problem that does not have a well

defined solution; by using an inappropriate numerical scheme; or simply using

incorrect settings for internal tolerances in the code. In addition, even high quality software can

contain bugs. Always treat the results

of a finite element computations with skepticism!

2.1 Introduction

The finite element method (FEM) is a computer

technique for solving partial differential equations. One application is to predict the deformation

and stress fields within solid bodies subjected to external forces. However, FEM can also be used to solve

problems involving fluid flow, heat transfer, electromagnetic fields,

diffusion, and many other phenomena.

The principle objective of the displacement based

finite element method is to compute the displacement

field within a solid subjected to external forces.

The principle objective of the displacement based

finite element method is to compute the displacement

field within a solid subjected to external forces.

To make this precise, visualize a solid deforming

under external loads. Every point in the

solid moves as the load is applied. The

displacement vector u(x) specifies the motion of the point at position x in the undeformed solid.

Our objective is to determine u(x). Once u(x)

is known, the strain and stress fields in the solid can be deduced.

There are two general types of finite element analysis

in solid mechancis. In most cases, we

are interested in determining the behavior of a solid body that is in static equilibrium. This means that both external and internal

forces acting on the solid sum to zero.

In some cases, we may be interested in the dynamic behavior of a solid body.

Examples include modeling vibrations in structures, problems involving

wave propagation, explosive loading and crash analysis.

For Dynamic

Problems the finite element method solves the equations of motion for a

continuum essentially a more complicated version of . Naturally, in this case it must calculate the motion of the solid as a

function of time.

For Static

Problems the finite element method solves the equilibrium equations . In this case, it may not be necessary to

calculate the time variation of motion.

However, some materials are history dependent (e.g metals deformed in

the plastic regime). In addition, a

static equilibrium problem may have more than one solution, depending on the

load history. In this case the time

variation of the solution must be computed.

For some applications, you may also need to solve

additional field equations. For example,

you may be interested in calculating the temperature distribution in the solid,

or calculating electric or magnetic fields.

In addition, special finite element procedures are available to

calculate buckling loads and their modes, as well as natural frequencies of

vibration and the corresponding mode shapes for a deformable solid.

To

set up a finite element calculation, you

will need to specify

1. The geometry of the solid. This is done by generating a finite element mesh for the solid. The mesh can usually be generated

automatically from a CAD representation of the solid.

2. The properties of the material. This is done by specifying a constitutive law for the solid.

3. The nature of the loading applied to the solid. This is done by specifying the boundary conditions for the problem.

4. If your

analysis involves contact between two more more solids, you will need to

specify the surfaces that are likely to come into contact, and the properties

(e.g. friction coefficient) of the contact.

5. For a dynamic analysis, it is necessary to specify initial conditions for the

problem. This is not necessary for a

static analysis.

6. For problems involving additional fields, you may need

to specify initial values for these field variables (e.g. you would need to

specify the initial temperature distribution in a thermal analysis).

You will also need to specify some additional aspects

of the problem you are solving and the solution procedure to be used:

1. You will need to specify whether the computation should take into

account finite changes in the geometry of the solid.

2. For a dynamic analysis, you will need to specify the time period

of the analysis (or the number of time increments)

3. For a static analysis you will need to decide whether the problem is

linear, or nonlinear. Linear problems

are very easy to solve. Nonlinear

problems may need special procedures.

4. For a static analysis

with history dependent materials you will need to specify the time period of

the analysis, and the time step size (or number of steps)

5. If you are

interested in calculating natural frequencies and mode shapes for the system,

you must specify how many modes to extract.

6. Finally, you will need to specify what the

finite element method must compute.

The

steps in running a finite element computation are discussed in more detail in

the following sections.

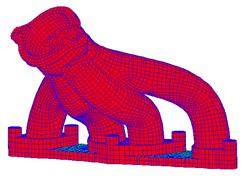

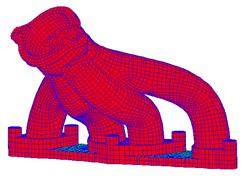

2.2 The

Finite Element Mesh for a 2D or 3D component

The finite element mesh is used to specify the

geometry of the solid, and is also used to describe the displacement field

within the solid. A typical mesh (generated

in the commercial FEA code ABAQUS) is shown in the picture to the right.

A finite element mesh may be three dimensional, like

the example shown. Two dimensional

finite element meshes are also used to model simpler modes of deformation. There are three main types of two dimensional

finite element mesh:

1. Plane stress

2. Plane strain

3. Axisymmetric

In addition, special types of finite element can be

used to model the overall behavior of a 3D solid, without needing to solve for

the full 3D fields inside the solid.

Examples are shell elements; plate elements; beam elements and truss

elements. These will be discussed in a

separate section below.

In addition, special types of finite element can be

used to model the overall behavior of a 3D solid, without needing to solve for

the full 3D fields inside the solid.

Examples are shell elements; plate elements; beam elements and truss

elements. These will be discussed in a

separate section below.

Plane

Stress Finite Element Mesh : A plane stress finite element mesh is used to

model a plate - like solid which is loaded in its own plane. The solid must have uniform thickness, and

the thickness must be much less than any representative cross sectional

dimension. A plane stress finite element

mesh for a thin plate containing a hole is shown in the figure to the right. Only on quadrant of the specimen is modeled,

since symmetry boundary conditions will be enforced during the analysis.

Plane

Stress Finite Element Mesh : A plane stress finite element mesh is used to

model a plate - like solid which is loaded in its own plane. The solid must have uniform thickness, and

the thickness must be much less than any representative cross sectional

dimension. A plane stress finite element

mesh for a thin plate containing a hole is shown in the figure to the right. Only on quadrant of the specimen is modeled,

since symmetry boundary conditions will be enforced during the analysis.

Plane Strain finite element mesh : A

plane strain finite element mesh is used to model a long cylindrical solid that

is prevented from stretching parallel to its axis. For example, a plane strain finite element

mesh for a cylinder which is in contact with a rigid floor is shown in the

figure. Away from the ends of the

cylinder, we expect it to deform so that the out of plane component of

displacement . There is no need to solve for ,

therefore, so a two dimensional mesh is sufficient to calculate and .

Plane Strain finite element mesh : A

plane strain finite element mesh is used to model a long cylindrical solid that

is prevented from stretching parallel to its axis. For example, a plane strain finite element

mesh for a cylinder which is in contact with a rigid floor is shown in the

figure. Away from the ends of the

cylinder, we expect it to deform so that the out of plane component of

displacement . There is no need to solve for ,

therefore, so a two dimensional mesh is sufficient to calculate and .

As before, only one quadrant of the specimen is

meshed: symmetry boundary conditions will be enforced during the analysis.

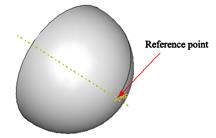

Axisymmetric finite element mesh: An

axisymmetric mesh is used to model a solids that has rotational symmetry, which

is subjected to axisymmetric loading. An

example is shown on the right.

Axisymmetric finite element mesh: An

axisymmetric mesh is used to model a solids that has rotational symmetry, which

is subjected to axisymmetric loading. An

example is shown on the right.

The picture compares a three dimensional mesh of an

axisymmetric bushing to an axisymmetric mesh.

Note that the half the bushing has been cut away in the 3D view, to show

the geometry more clearly. In an

axisymmetric analysis, the origin for the (x,y)

coordinate system is always on the axis of

rotational symmetry. Note also

that to run an axisymmetric finite element analysis, both the geometry of the

solid, and also the loading applied to the solid, must have rotational symmetry

about the y axis.

2.2.1 Nodes and Elements in a Mesh

A finite element mesh is defined by a set of nodes together with a set of finite elements, as shown in the sketch on

the right.

A finite element mesh is defined by a set of nodes together with a set of finite elements, as shown in the sketch on

the right.

Nodes: The

nodes are a set of discrete points within the solid body. Nodes have the following properties:

Nodes: The

nodes are a set of discrete points within the solid body. Nodes have the following properties:

1. A node

number. Every node is assigned an integer number,

which is used to identify the node. Any

convenient numbering scheme may be selected the nodes do not need to be numbered in order,

and numbers may be omitted. For example,

one could number a set of n nodes as

100, 200, 300… 100n, instead of

1,2,3…n.

2. Nodal

coordinates. For a three dimensional finite element

analysis, each node is assigned a set of

coordinates, which specifies the position of

the node in the undeformed solid. For a

two dimensional analysis, each node is assigned a pair of coordinates.

For an axisymmetric analysis, the axis must coincide with the axis of rotational

symmetry.

3. Nodal

displacements. When the solid deforms, each node moves to a

new position. For a three dimensional

finite element analysis, the nodal displacements specify the three components

of the displacement field u(x) at each node: . For a two dimensional analysis, each node has

two displacement components . The nodal displacements are unknown at the

start of the analysis, and are computed by the finite element program.

4. Other nodal

degrees of freedom. For more complex

analyses, we may wish to calculate a temperature distribution in the solid, or

a voltage distribution, for example. In

this case, each node is also assigned a temperature, voltage, or similar quantity

of interest. There are also some finite

element procedures which use more than just displacements to describe shape

changes in a solid. For example, when

analyzing two dimensional beams, we use the displacements and rotations of the

beam at each nodal point to describe the deformation. In this case, each node has a rotation, as

well as two displacement components. The

collection of all unknown quantities (including displacements) at each node are

known as degrees of freedom. A finite element program will compute values

for these unknown degrees of freedom.

Elements

are used to partition the solid into discrete regions. Elements have the following properties.

Elements

are used to partition the solid into discrete regions. Elements have the following properties.

1. An element

number. Every element is assigned an integer number,

which is used to identify the element.

Just as when numbering nodes, any convenient scheme may be selected to

number elements.

2. A geometry. There are many

possible shapes for an element. A few of

the more common element types are shown in the picture. Nodes attached to the element are shown in

red. In two dimensions, elements are

generally either triangular or rectangular. In three dimensions, the elements

are generally tetrahedra, hexahedra or bricks.

There are other types of element that are used for special purposes:

examples include truss elements (which are simply axial members), beam

elements, and shell elements.

3. A set of

faces. These are simply the sides of the element.

4. A set of

nodes attached to the element. The picture on the right shows a typical

finite element mesh. Element numbers are

shown in blue, while node numbers are shown in red (some element and node

numbers have been omitted for clarity).

All the elements are 8 noded quadrilaterals. Note that each element is connected to a set

of nodes: element 1 has nodes (41, 45, 5, 1, 43, 25, 3, 21), element 2 has

nodes (45, 49, 9, 5, 47, 29, 7, 25), and so on.

It is conventional to list the nodes the nodes in the order given, with

corner nodes first in order going counterclockwise around the element, followed

by the midside nodes. The set of nodes

attached to the element is known as the element

connectivity.

5. An element

interpolation scheme. The purpose of a finite element is to

interpolate the displacement field u(x)

between values defined at the nodes.

This is best illustrated using an example. Consider the two dimensional, rectangular 4

noded element shown in the figure. Let ,

,

,

denote the components of displacement at nodes

a, b, c, d. The displacement at an arbitrary point within

the element can be interpolated between values at the corners, as follows

where

You can verify for yourself that the displacements

have the correct values at the corners of the element, and the displacements

evidently vary linearly with position within the element.

Different types of element interpolation scheme

exist. The simple example described

above is known as a linear

element. Six noded triangles and 8 noded

triangles are examples of quadratic

elements: the displacement field varies quadratically with position within the

element. In three dimensions, the 4

noded tetrahedron and the 8 noded brick are linear elements, while the 10 noded

tet and 20 noded brick are quadratic.

Other special elements, such as beam elements or shell elements, use a

more complex procedure to interpolate the displacement field.

Some special types of element interpolate both the

displacement field and some or all components of the stress field within an

element separately. (Usually, the displacement interpolation is sufficient to

determine the stress, since one can compute the strains at any point in the

element from the displacement, and then use the stressstrain relation

for the material to find the stress). This type of element is known as a hybrid element. Hybrid elements are usually used to model

incompressible, or nearly incompressible, materials.

6. Integration

points. One objective of a finite element analysis is

to determine the distribution of stress within a solid. This is done as follows. First, the displacements at each node are

computed (the technique used to do this will be discussed in Section 7.2 and

Chapter 8.) Then, the element

interpolation functions are used to determine the displacement at arbitrary

points within each element. The

displacement field can be differentiated to determine the strains. Once the strains are known, the stressstrain relations

for the element are used to compute the stresses.

In principle, this procedure could be used to

determine the stress at any point within an element. However, it turns out to work better at some

points than others. The special points

within an element where stresses are computed most accurately are known as integration points. (Stresses are sampled at these points in the

finite element program to evaluate certain volume and area integrals, hence

they are known as integration points).

For a detailed description of the locations of

integration points within an element, you should consult an appropriate user

manual. The approximate locations of

integration points for a few two dimensional elements are shown in the figure.

There are some special types of element that use fewer

integration points than those shown in the picture. These are known as reduced integration elements. This type of element is usually less

accurate, but must be used to analyze deformation of incompressible materials

(e.g. rubbers or rigid plastic metals).

7. A stressstrain relation

and material properties. Each element is occupied by solid

material. The type of material within

each element (steel, concrete, soil, rubber, etc) must be specified, together

with values for the appropriate material properties (mass density, Young’s

modulus, Poisson’s ratio, etc).

2.2.2 Special

Elements Beams, Plates, Shells and Truss elements

2.2.2 Special

Elements Beams, Plates, Shells and Truss elements

If you need to analyze a solid with a special geometry

(e.g. a simple truss, a structure made of one or more slender beams, or plates)

it is not efficient to try to generate a full 3D finite element mesh for each

member in the structure. Instead, you

can take advantage of the geometry to simplify the analysis.

The idea is quite simple. Instead of trying to calculate the full 3D

displacement field in each member, the deformation is characterized by a

reduced set of degrees of freedom.

Specifically:

1. For a pin jointed truss, we simply calculate the displacement of each joint in the

structure. The members are assumed to be in a state of uniaxial tension or

compression, so the full displacement field within each member can be

calculated in terms of joint displacements.

2. For a beam, we calculate the displacement and rotation of the cross section along the beam. These can be used to determine the internal

shear forces bending moments, and therefore the stresses in the beam. A three

dimensional beam has 3 displacement and 3 rotational degrees of freedom at each

node.

3.  For a plate, or shell, we again calculate the displacement and rotation of the plate

section. A three dimensional plate or shell has 3 displacement and two rotational degrees of freedom at

each node (these rotations characterize the rotation of a unit vector normal to

the plate). In some finite element

codes, nodes on plates and shells have a fictitious third rotational degree of

freedom which is added for convenience but you will find that attempting to impose

boundary conditions on this fictitious degree of freedom has no effect on the

deformation of the structure.

For a plate, or shell, we again calculate the displacement and rotation of the plate

section. A three dimensional plate or shell has 3 displacement and two rotational degrees of freedom at

each node (these rotations characterize the rotation of a unit vector normal to

the plate). In some finite element

codes, nodes on plates and shells have a fictitious third rotational degree of

freedom which is added for convenience but you will find that attempting to impose

boundary conditions on this fictitious degree of freedom has no effect on the

deformation of the structure.

In

an analysis using truss, beam or plate elements, some additional information

must be specified to set up the problem:

1. For a truss analysis, each member in the truss is a

single element. The area of the member’s

cross section must be specified.

2. For a beam analysis, the shape and orientation of the

cross section must be specified (or, for an elastic analysis, you could specify

the area moments of inertia directly).

There are also several versions of beam theory, which account

differently for shape changes within the beam.

Euler-Bernoulli beam theory is the simple version covered in

introductory courses. Timoshenko beam

theory is a more complex version, which is better for thicker beams.

3. For plates and shells, the thickness of the plate must

be given. In addition, the deformation

of the plate can be approximated in various ways for example, some versions only account for

transverse deflections, and neglect in-plane shearing and stretching of the

plate; more complex theories account for this behavior.

Calculations using beam and plate theory also differ

from full 3D or 2D calculations in that both the deflection and rotation of the beam or plate must

be calculated. This means that:

1. Nodes on beam elements have 6 degrees of freedom the three displacement components, together

with three angles representing rotation of the cross-section about three axes. Nodes on plate or shell elements have 5 (or

in some FEA codes 6) degrees of freedom.

The 6 degrees of freedom represent 3 displacement components, and two

angles that characterize rotation of the normal to the plate about two axes (if

the nodes have 6 degrees of freedom a third, fictitious rotation component has

been introduced you will have to read the manual for the code

to see what this rotation represents).

2. Boundary conditions may constrain both displacement

and rotational degrees of freedom. For

example, to model a fully clamped boundary condition at the end of a beam (or

the edge of a plate), you must set all displacements and all rotations to zero.

3.

You can apply

both forces and moments to nodes in an analysis.

Finally,

in an analysis involving several beams connected together, you can connect the

beams in two ways:

1. You can connect them with a pin joint, which forces the beams to move together at the

connection, but allows relative rotation

2. You can connect them with a clamped joint, which forces the beams to rotate together at the

connection.

In most FEA codes, you can create the joints by adding

constraints, as discussed in Section 1.2.6 below. Occasionally, you may also

wish to connect beam elements to solid, continuum elements in a model: this can

also be done with constraints.

2.3 Material

Behavior

A good finite element code contains a huge library of

different types of material behavior that may be assigned to elements. A few examples are described below.

A good finite element code contains a huge library of

different types of material behavior that may be assigned to elements. A few examples are described below.

Linear

Elasticity. You should alreadly be

familiar with the idea of a linear elastic material. It has a uniaxial stressstrain response

(valid only for small strains) as shown in the picture

Linear

Elasticity. You should alreadly be

familiar with the idea of a linear elastic material. It has a uniaxial stressstrain response

(valid only for small strains) as shown in the picture

The

stress--strain law for the material may be expressed in matrix form as

Here, E and v are Young’s modulus and Poisson’s

ratio for the material, while denotes the thermal expansion coefficient. Typical values (for steel) are E=210 GN/ , v=0.33, .

, v=0.33, .

Elasticplastic material

behavior is usually used to model metals that are subjected to large

stresses, but there are also versions of plastic stress-strain laws that model

soils and concrete.

Elasticplastic material

behavior is usually used to model metals that are subjected to large

stresses, but there are also versions of plastic stress-strain laws that model

soils and concrete.

An elastic-plastic material behaves elastically until

a critical stress (known as the yield stress) is reached. If yield is exceeded, the material deforms

permanently. The yield stress of the matierial

generally increases with plastic strain: this behavior is known as strain hardening.

The conditions necessary to initiate yielding under

multiaxial loading are specified by a yield

criterion, such as the Von-Mises or Tresca criteria. These yield criteria are built into the

finite element code.

The strain hardening behavior of a material is

approximated by allowing the yield stress to increase with plastic strain. The variation of yield stress with plastic

strain for a material is usually specified by representing it as a series of

straight lines, as shown in the picture.

A typical yield stress for a metal might vary from

80Mpa (for a material like pure aluminum) to 1 GPa (for a high-strength steel).

Hyperelasticity

is intended to model rubbery materials (or elastomeric foams, like a sponge)

which have (i) a reversible stress-v-strain relation and (ii) the stress is

independent of strain rate or loading history.

They are intended to model large changes in shape of the material

(that’s what the ‘hyper’ refers to).

This means that the stress-v-strain relation has to be defined rather

carefully, because there are several choices of stress and strain measure (e.g.

we could use ‘true’ stress or ‘nominal’ stress; similarly we could use

‘engineering’ strain or ‘true’ strain).

Hyperelasticity

is intended to model rubbery materials (or elastomeric foams, like a sponge)

which have (i) a reversible stress-v-strain relation and (ii) the stress is

independent of strain rate or loading history.

They are intended to model large changes in shape of the material

(that’s what the ‘hyper’ refers to).

This means that the stress-v-strain relation has to be defined rather

carefully, because there are several choices of stress and strain measure (e.g.

we could use ‘true’ stress or ‘nominal’ stress; similarly we could use

‘engineering’ strain or ‘true’ strain).

The simplest hyperelastic material model is the

so-called ‘neo-Hookean’ material. This model

is intended to predict the behavior of rubbers, which resist volume changes,

but deform very easily when subjected to shear stress. It has two material properties: (i) a shear

modulus , and (ii) a bulk modulus K. The bulk modulus is

always much greater than the shear modulus and (especially in hand

calculations) is often assumed to be infinite (which means the material is

incompressible). In uniaxial tension,

an incompressible neo-Hookean material has a uniaxial stress-v-stretch relation

of the form

The simplest hyperelastic material model is the

so-called ‘neo-Hookean’ material. This model

is intended to predict the behavior of rubbers, which resist volume changes,

but deform very easily when subjected to shear stress. It has two material properties: (i) a shear

modulus , and (ii) a bulk modulus K. The bulk modulus is

always much greater than the shear modulus and (especially in hand

calculations) is often assumed to be infinite (which means the material is

incompressible). In uniaxial tension,

an incompressible neo-Hookean material has a uniaxial stress-v-stretch relation

of the form

where is the nominal stress (force per unit undeformed

area) in the specimen, and is the ratio of deformed length to original

length of the specimen. The curve is

shown in the figure.

A typical value for the shear modulus of a rubber

might be 0.5MPa.

Linear

Viscoelasticity is used to model polymers or biological tissues that are

subjected to modest strains (less than 0.5%).

A typical application might be to model the energy dissipation during

cyclic loading of a polymeric vibration damper, or to model human tissue

responding to an electric shaver.

Linear

Viscoelasticity is used to model polymers or biological tissues that are

subjected to modest strains (less than 0.5%).

A typical application might be to model the energy dissipation during

cyclic loading of a polymeric vibration damper, or to model human tissue

responding to an electric shaver.

Viscoelastic

materials have a time-dependent response, which can be measured in two

different ways:

1. Take a specimen that is free of stress at time ,

apply a constant shear stress for and measuring the resulting shear strain as a function of time. The results are generally presented by

plotting the `creep compliance’ as a function of time.

2.

Take a specimen that is

free of stress at time ,

apply a constant shear strain for and measuring the resulting shear stress as a function of time. In this case the

results are presented by plotting the Relaxation Modulus:

Similar

experiments can be done to measure the response of the material to pressure (or

volume changes) but in many practical applications the time-dependence of the

pressure or volume is negligible, and the material can be assumed to have a

constant bulk modulus.

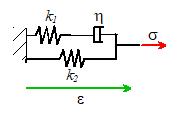

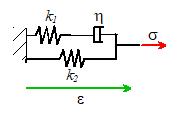

In

finite element simulations the time dependence of shear (and if necessary bulk)

modulus is usually specified by entering values for the so-called ‘Prony

series’ for the material

where is the steady-state stiffness (represented by the

parallel spring), and are a set of time constants and stiffnesses. The Prony series can be interpreted as a

complicated spring-damper model for the material behavior. For example, the spring-damper system shown

in the figure is a useful simple viscoelastic mode. It has a Prony series

2.4 Boundary

conditions, Constraints, Interfaces and Contact

Boundary conditions are used to specify the loading

applied to a solid. There are several

ways to apply loads to a finite element mesh:

Displacement

boundary conditions. The

displacements at any node on the boundary or within the solid can be

specified. One may prescribe ,

,

,

or all three. For a two dimensional

analysis, it is only necessary to prescribe and/or .

Displacement

boundary conditions. The

displacements at any node on the boundary or within the solid can be

specified. One may prescribe ,

,

,

or all three. For a two dimensional

analysis, it is only necessary to prescribe and/or .

Various symbols are used to denote displacement

boundary conditions applied to a finite element mesh: a few of these are illustrated

in the figure on the right. Some

user-interfaces use small conical arrowheads to indicate constrained displacement

components.

For example, to stretch a 2D block of material

vertically, while allowing it to expand or contract freely horizontally, we

would apply boundary constraints to the top and bottom surface as shown in the

figure.

Observe that one of the nodes on the bottom of the

block has been prevented from moving horizontally, as well as vertically. It is important to do this: the finite

element program will be unable to find a unique solution for the displacement

fields if the solid is free to slide horizontally.

During the analysis, the finite element program will

apply forces to the nodes with prescribed displacements, so as to cause them to

move to their required positions. If

only the component of displacement is prescribed, then

the force will act in the direction.

If is prescribed, the force acts in direction ,

and so on. Notice that you cannot directly apply a rotation to a node attached to a 2D or 3D solid. Rotations can, however, be applied to the

nodes attached to certain special types of element, such as beams, plates and

shells, as well as rigid surfaces.

Symmetry

conditions: Most finite element codes can automatically enforce symmetry

and anti-symmetry boundary conditions.

Symmetry

conditions: Most finite element codes can automatically enforce symmetry

and anti-symmetry boundary conditions.

Prescribed

forces. Any node in a finite element mesh may be subjected to a prescribed

force. The nodal force is a vector, and

is specified by its three (or two for 2D) components, . Notice there is no direct way to apply a moment to a 3D solid you would need to do this by applying two

point forces a small distance apart, or by applying contact loading, as

outlined below. Moments can be applied

to some special types of element, such as shells, plates or beams.

Prescribed

forces. Any node in a finite element mesh may be subjected to a prescribed

force. The nodal force is a vector, and

is specified by its three (or two for 2D) components, . Notice there is no direct way to apply a moment to a 3D solid you would need to do this by applying two

point forces a small distance apart, or by applying contact loading, as

outlined below. Moments can be applied

to some special types of element, such as shells, plates or beams.

Distributed

loads. A solid may be subjected to

distributed pressure or traction acting on ints boundary. Examples include aerodynamic loading, or

hydrostatic fluid pressure. Distributed traction is a vector quantity, with physical dimensions of

force per unit area in 3D, and force per unit length in 2D. To model this type of loading in a finite

element program, distributed loads may be applied to the the face of any

element.

Distributed

loads. A solid may be subjected to

distributed pressure or traction acting on ints boundary. Examples include aerodynamic loading, or

hydrostatic fluid pressure. Distributed traction is a vector quantity, with physical dimensions of

force per unit area in 3D, and force per unit length in 2D. To model this type of loading in a finite

element program, distributed loads may be applied to the the face of any

element.

Default

boundary condition at boundary nodes.

If no displacements or forces are prescribed at a boundary node, and no

distributed loads act on any element faces connected to that node, then the

node is assumed to be free of external force.

Default

boundary condition at boundary nodes.

If no displacements or forces are prescribed at a boundary node, and no

distributed loads act on any element faces connected to that node, then the

node is assumed to be free of external force.

Body

forces. External body forces may act

on the interior of a solid. Examples of

body forces include gravitational loading, or electromagnetic forces. Body force is a vector quantity, with

physical dimensions of force per unit volume.

To model this type of loading in a finite element program, body forces

may be applied to the interior of any element.

Body

forces. External body forces may act

on the interior of a solid. Examples of

body forces include gravitational loading, or electromagnetic forces. Body force is a vector quantity, with

physical dimensions of force per unit volume.

To model this type of loading in a finite element program, body forces

may be applied to the interior of any element.

Contact. Probably the most common way to load a solid

is through contact with another solid.

Special procedures are available for modeling contact between solids these will be discussed in a separate section

below.

Contact. Probably the most common way to load a solid

is through contact with another solid.

Special procedures are available for modeling contact between solids these will be discussed in a separate section

below.

Load

history. In some cases, one may wish

to apply a cycle of load to a solid. In

this case, the prescribed loads and displacements must be specified as a

function of time.

Load

history. In some cases, one may wish

to apply a cycle of load to a solid. In

this case, the prescribed loads and displacements must be specified as a

function of time.

General

guidelines concerning boundary conditions.

When performing a static analysis, it is very important to make sure

that boundary conditions are applied properly.

A finite element program can only solve a problem if a unique static

equilibrium solution to the problem exists.

General

guidelines concerning boundary conditions.

When performing a static analysis, it is very important to make sure

that boundary conditions are applied properly.

A finite element program can only solve a problem if a unique static

equilibrium solution to the problem exists.

Difficulties arise if the user does not specify sufficient

boundary constraints to prevent rigid body motion of a solid. This is best illustrated by example. Suppose we wish to model stretching a 2D

solid, as described earlier. The

examples to the right show two correct ways to do this.

The examples below show various incorrect ways to

apply boundary conditions. In each case,

one or more rigid body mode is unconstrained.

2.4.1 Constraints

You may sometimes need to use more complicated

boundary conditions than simply constraining the motion or loads applied to a

solid. Some examples might be

1.

Connecting

different element types, e.g. beam elements to solid elements;

2.

Enforcing

periodic boundary conditions

3.

Constraining a

boundary to remain flat

4.

Approximating the

behavior of mechanical components such as welds, bushings, bolted joints, etc.

You can do this by defining constraints in an analysis.

At the most basic level, constraints can simply be used to enforce

prescribed relationships between the displacements or velocities of individual

nodes in the mesh. You can also specify

relationships between motion of groups

of nodes.

2.4.2 Contacting Surfaces and Interfaces

In addition to being subject to forces or prescribed

displacements, solid objects are often loaded by coming into contact with

another solid.

Modern finite element codes contain sophisticated

capabilities for modeling contact.

Unfortunately, contact can make a computation much more difficult,

because the region where the two solids come into contact is generally not

known a priori, and must be

determined as part of the solution. This

almost always makes the problem nonlinear

even if both contacting solids are linear

elastic materials. In addition, if there

is friction between the contacting solids, the solution is history dependent.

For

this reason, many options are available in finite element packages to control

the way contacting surfaces behave.

There

are three general cases of contact that you may need to deal with:

1. A deformable solid contacts a stiff, hard solid whose

deformation may be neglected. In this

case the hard solid is modeled as a rigid

surface, as outlined below.

2.

You may need to

model contact between two deformable solids

3. The solid comes into contact with itself during the

course of deformation (this is common in components made from rubber, for

example, and also occurs during some metal forming operations).

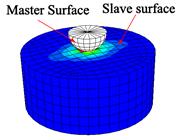

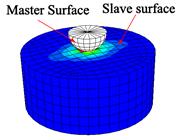

Whenever

you model contact, you will need to

1. Specify pairs of surfaces that might come into

contact. One of these must be designated

as the master surface and the other

must be designated as the slave surface. (If

a surface contacts itself, it is both a master and a slave. Kinky!)

2. Define the way the two surfaces interact, e.g. by

specifying the coefficient of friction between them.

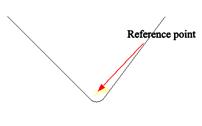

Modeling

a stiff solid as a rigid surface: In

many cases of practical interest one of the two contacting solids is much more

compliant than the other. Examples

include a rubber in contact with metal, or a metal with low yield stress in

contact with a hard material like a ceramic.

As long as the stresses in the stiff or hard solid are not important,

its deformation can be neglected.

Modeling

a stiff solid as a rigid surface: In

many cases of practical interest one of the two contacting solids is much more

compliant than the other. Examples

include a rubber in contact with metal, or a metal with low yield stress in

contact with a hard material like a ceramic.

As long as the stresses in the stiff or hard solid are not important,

its deformation can be neglected.

In

this case the stiffer of the two solids may be idealized as a rigid surface. Both 2D and 3D rigid surfaces can be created,

as shown in the figure.

A rigid surface (obviously) can’t change its shape,

but it can move about and rotate. Its

motion is defined using a reference point

on the solid, which behaves like a node.

To move the solid around during an analyisis, you can define

displacement and rotational degrees of freedom at this node. Alternatively, you could apply forces and

moments to the reference point.

Finally, in a dynamic analysis, you can give the rigid solid appropriate

inertial properties (so as to create a rigid projectile, for example).

Defining

a contact pair master/slave surfaces: Whenever you set up

a finite element calculation that involves contact, you need to specify pairs

of surfaces that may come into contact during the analysis. One of each pair must be designated the master surface, the other must be

designated the slave surface.

Defining

a contact pair master/slave surfaces: Whenever you set up

a finite element calculation that involves contact, you need to specify pairs

of surfaces that may come into contact during the analysis. One of each pair must be designated the master surface, the other must be

designated the slave surface.

This rather obscure finite element terminology refers

to the way that contact constraints are actually applied during a

computation. The geometry of the master

surface will be interpolated as a smooth curve in some way (usually by

interpolating between nodes). The slave

surface is not interpolated. Instead,

each individual node on the slave surface is constrained so as not to penetrate

into the master surface. For example,

the red nodes on the slave surface shown in the figure would be forced to

remain outside the red boundary of the master surface.

For a sufficiently fine mesh, the results should not

be affected by your choice of master and slave surface. However, it improves convergence (see below to learn what this means) if you choose the

more rigid of the two surfaces to be the master surface. If you don’t know which surface is more

rigid, just make a random choice. If you

run into convergence problems later, try switching them over.

Contact

parameters You can define several parameters that control the behavior of

two contacting surfaces:

Contact

parameters You can define several parameters that control the behavior of

two contacting surfaces:

1. The contact formulation - `finite sliding’ or `small

sliding’ specifies the expected relative tangential

displacement of the two surfaces.

`Finite sliding’ is the most general, but is computationally more

demanding. `Small sliding’ should be

used if the relative tangential displacement is likely to be less than the

distance between two adjacent nodes.

2. You can specify the relationship between the contact

pressure and separation between the contacting surfaces. Alternatively, you can

assume the contact is `hard’ this means the interface can’t withstand any

tension, and the two contacting surfaces cannot inter-penetrate.

3.

You can specify

the tangential behavior of the interface for example by giving the friction

coefficient.

2.5 Initial

Conditions and external fields

For a dynamic analysis, it is necessary to specify the

initial velocity and displacement of each node in the solid. The default value is zero velocity and

displacement.

In addition, if you are solving a coupled problem one involving coupled deformation and heat

flow, for example - you may need to specify initial values for the additional

field variables (e.g. the temperature distribution)

2.6 Solution

procedures and time increments

The finite element method calculates the displacement at each node in the finite element mesh by

solving the equations of static equilibrium or the equations of motion. In this section, we briefly outline some of

the solution procedures, and the options available to control them.

Linear

or Nonlinear Geometry As you know, you can simplify the calculation of

internal forces in a structures by neglecting shape changes when solving the

equations of equilibrium. For example,

when you solve a truss problem, you usually calculate forces in each member

based on the undeformed shape of the

structure.

Linear

or Nonlinear Geometry As you know, you can simplify the calculation of

internal forces in a structures by neglecting shape changes when solving the

equations of equilibrium. For example,

when you solve a truss problem, you usually calculate forces in each member

based on the undeformed shape of the

structure.

You can use the same idea to simplify calculations

involving deformable solids. In general,

you should do so whenever possible.

However, if either

1. You anticipate that material might stretch by more

than 10% or so or

2. You expect that some part of the solid might rotate by

more than about 10 degrees

3. You wish to calculate buckling loads for your

structure

you should account for finite geometry changes in the

computation. This will automatically

make your calculation nonlinear (and so more difficult), even if all the

materials have linear stress-strain relations.

Time

stepping for dynamic problems: For a dynamic problem, the nodal

displacements must be calculated as a function of

time. The displacements are calculated

by solving the equations of motion for the system, which look something like

Time

stepping for dynamic problems: For a dynamic problem, the nodal

displacements must be calculated as a function of

time. The displacements are calculated

by solving the equations of motion for the system, which look something like

where M and

K are called mass and stiffness

matrices. Both M and K can be functions

of u. There are 2.5 ways to integrate this

equation.

1. The most direct method is called explicit time integration, or explicit

dynamics and works something like this.

Remember that for a dynamic calculation, the values of u and are known at t=0. We can therefore

compute M and K at time t=0, and then

use them to calculate the acceleration at t=0,

as

The acceleration can

then be used to find the velocity and displacement at time as

This procedure can

then be applied repeatedly to march the solution through time.

2. The second procedure is called implicit time integration or implicit

dynamics. The procedure is very

similar to explicit time integration, except that instead of calculating the

mass and stiffness matrices at time t=0,

and using them to calculate acceleration at t=0,

these quantities are calculated at time instead.

This is a bit more time consuming to do, however, because it involves

more equation solving.

3. The 2.5th method is called Modal Dynamics and only works if M and K are constant. In this

case one can take the Fourier transform of the governing equation and integrate

it exactly. This method is used to solve

linear vibration problems.

The

following guidelines will help you to choose the most appropriate method for

your application:

1. For explicit

dynamics each time step can be calculated very fast. However, the method is stable only if is very small specifically, the time interval must be

smaller than the time taken for an elastic wave to propagate from one side of

an element to the other. This gives ,

where is the mass density of the solid, is its shear modulus and its Poisson’s ratio. Explicit dynamics works best for rapid,

transient problems like crash dynamics or impact. It is not good for modeling processes that

take place over a long time. If elastic

wave propagation is not the main focus of your computation, you can sometime

speed up the calculations by increasing the density (but you have to be careful to make sure this

does not affect the results). This is

called mass scaling.

2. For implicit

dynamics the cost of computing each time step is much greater. The algorithm is unconditionally stable,

however, and will always converge even for very large . This is the method of choice for problems

where inertial loading is important, but rapid transients are not the focus of

the analysis.

3. Modal

Dynamics only works for linear

elastic problems. It is used for

vibration analysis.

Nonlinear

Solution Procedures for Static Problems: If a problem involves contact,

plastically deforming materials, or large geometry changes it is nonlinear. This means that the equations of static

equilibrium for the finite element mesh have the general form

Nonlinear

Solution Procedures for Static Problems: If a problem involves contact,

plastically deforming materials, or large geometry changes it is nonlinear. This means that the equations of static

equilibrium for the finite element mesh have the general form

where F() denotes

a set of b=1,2…N vector functions of

the nodal displacements ,

a=1,2…N, and N is the number of nodes in the mesh.

The nonlinear equations are solved using the

Newton-Raphson method, which works like this.

You first guess the solution to the equations say . Of course (unless you are a genius) w won’t satisfy the equations, so you

try to improve the solution by adding a small correction . Ideally, the correction should be chosen so

that

but

of course it’s not possible to do this.

So instead, take a Taylor

expansion to get

The result is a system of linear equations of the form

,

where is a constant matrix called the stiffness matrix. The equations can now be solved for ;

the guess for w can be corrected,

and the procedure applied over again.

The iteration is repeated until ,

where is a small tolerance.

In problems involving hard contact, an additional iterative method is used to decide

which nodes on the slave surface contact the master surface. This is just a brute-force method it starts with some guess for contacting

nodes; gets a solution, and checks it.

If any nodes are found to penetrate the master surface, these are added

to the list of nodes in contact. If any

nodes are experiencing forces attracting them to the master surface, they are

removed from the list of nodes in contact.

The problem with any iterative procedure is that it

may not converge that is, repeated corrections either take the solution further and further

away from the solution, or else just spiral around the solution without every

reaching it.

The solution is (naturally) more likely to converge if

the guess is close to the correct solution. Consequently, it is best to apply the loads

to a nonlinear solid gradually, so that at each load step the displacements are

small. The solution to one load

increment can then be used as the initial guess for the next.

Convergence problems are the curse of FEM

analysts. They are very common and can

be exceedingly difficult to resolve.

Here are some suggestions for things to try if you run into convergence

problems:

1. Try applying the load in smaller increments. most commercial codes will do this this

automatically but will stop the computation if the increment

size falls below a minimum value. You

can try reducing the minimum step size..

2. Convergence problems are sometimes caused by ill conditioning in the stiffness

matrix. This means that the equations cannot be solved accurately. Ill conditioning can arise because of (i)

severely distorted elements in the mesh; (ii) material behavior is

incompressible, or nearly incompressible; and (iii) The boundary conditions in

the analysis do not properly constrain the solid. You can fix (i) by modifying

the mesh some FEM codes contain capabilities to

automatically remove element distorsion during large deformation. You can avoid

problems with incompressibility (ii) by using reduced integration elements or

hybrid elements. Problems with boundary

conditions (iii) can usually be corrected by adding more constraints. There is one common problem where this is

hard to do if the motion of a body in your analysis is

constrained only by contacts with other solids (e.g. a roller between two surfaces)

the stiffness matrix is always singular at the start of the analysis. Some finite element codes contain special

procedures to deal with this problem.

3. Try to isolate the source of the problem. Convergence issues can often be traced to one

or more of the following: (i) Severe material nonlinearity; (ii) Contact and

(iii) Geometric nonlinearity. Try to

change your model to remove as many of these as possible e.g. if you are doing a plasticity computation

with contact and geometric nonlinearity, try doing an elastic calculation and

see if it works. If so, the problems are

caused by material nonlinearity.

Similarly, try analyzing the two contacting solids separately, without

the contact; or try the computation without nonlinear geometry. Once you’ve traced the source of the problem,

you might be able to fix it by changing the material properties, contact

properties or loading conditions.

4. Convergence problems are often caused by some kind of

mechanical or material failure in the solid, which involve a sudden release of

energy. In this case, the shape of the

solid may suddenly jump from one static equilibrium configuration to another,

quite different, equilibrium configuration.

There is a special type of loading procedure (called the Riks method) that

can be used to stabilize this kind of problem.

5. Some boundary value problems have badly behaved

governing equations. For example, the

equations governing plane strain deformation of a perfectly plastic solid

become hyperbolic for sufficiently large strains. Static FEM simply won’t work for these

problems. Your best bet is to try an

explicit dynamic calculation instead, perhaps using mass scaling to speed up

the calculation.

Load steps and increments: When you set

up a finite element model, you usually apply the load in a series of

steps. You can define different boundary

conditions in each step. Unless you

specify otherwise, the loads (or displacements) will vary linearly from their

values at the start of the step to their values at the end of the step, as

illustrated in the picture.

Load steps and increments: When you set

up a finite element model, you usually apply the load in a series of

steps. You can define different boundary

conditions in each step. Unless you

specify otherwise, the loads (or displacements) will vary linearly from their

values at the start of the step to their values at the end of the step, as

illustrated in the picture.

In a nonlinear analysis, the solution may not converge

if the load is applied in a single increment.

If this is the case, the load must be applied gradually, in a series of

smaller increments. Many finite element

codes will automatically reduce the time step if the solution fails to

converge.

2.7 Output

The finite element method always calculates the displacement of each node in the mesh these are the unknown variables in the

computation. However, these may not be

the quantities you are really interested in.

A number of quantities can be computed from the displacement fields,

including:

1. Velocity and acceleration fields

2. Strain components, principal strains, and strain

invariants,or their rates

3. Elastic and plastic strains or strain rates

4. Stress components; principal stresses; stress

invariants

5. Forces applied to nodes or boundaries

6. Contact pressures

7. Values of material state variables (e.g. yield

stresses)

8. Material failure criteria

All these quantities can be computed as functions of

time at selected points in the mesh (either at nodes, or at element integration

points); as functions of position along paths connecting nodes; or as contour

plots.

2.8 Units in finite element computations, using dimensional analysis

A finite element code merely solves the equations of

motion (or equilibrium), together with any equations governing material

behavior. Naturally, equations like F=ma

and do not contain any units a priori. Consequently, when

entering geometric dimensions, material data and loads into an FEA code, you can use any system of units you like,

but the units of all quantities must be consistent. You have to be very careful with this. When you sketch the part you are modeling, it

is often convenient to enter dimensions in cm, inches, or mm. This is fine but then cm,

inches or mm must be used for any other material or load data that contain

length dimensions. For example, if

you use cm to dimension your part, then you must enter data for Young’s modulus

and yield stress in ,

and you must also specify pressures acting on the system in . In this case, the FEA code will report

stresses in units of .

Using

Dimensional Analysis to simplify FEA analysis.

Using

Dimensional Analysis to simplify FEA analysis.

You may have used dimensional analysis to find

relationships between data measured in an experiment (especially in fluid

mechanics). The same idea can be used to

relate variables you might compute in an FEA analysis (e.g. stress), to the

material properties of your part (e.g. Young’s modulus) and the applied

loading.

You may have used dimensional analysis to find

relationships between data measured in an experiment (especially in fluid

mechanics). The same idea can be used to

relate variables you might compute in an FEA analysis (e.g. stress), to the

material properties of your part (e.g. Young’s modulus) and the applied

loading.

The basic idea is simple, and is best illustrated by

example. Suppose we wish to use FEA to

calculate the deflection of the tip of a cantilever with length L, Young’s modulus E and area moment of inertia I,

which is subjected to a force P. We would set this up as an FEA problem,

entering data for L, E, I,

and P in the code, and computing . We could express the functional relationship

as

If we were asked to calculate the function f numerically, we would have to run

simulations where we vary E, I, L and P independently. This would be very painful. Fortunately, since the

relationship must be independent of the system of units, we know we can

re-write this expression so that both left and right hand side are dimensionless i.e. as combinations of variables that have no units. Noting that and L

have dimensions of length, I has

dimensions of ,

P has dimensions and E has

dimensions of ,

we could put

If we were asked to calculate the function f numerically, we would have to run

simulations where we vary E, I, L and P independently. This would be very painful. Fortunately, since the

relationship must be independent of the system of units, we know we can

re-write this expression so that both left and right hand side are dimensionless i.e. as combinations of variables that have no units. Noting that and L

have dimensions of length, I has

dimensions of ,

P has dimensions and E has

dimensions of ,

we could put

Now, we only need to calculate the function g.

We could do this by keeping L

and I fixed, and varying P to see the results of varying the

first group; we could then keep P and

L fixed and vary I to see the effect of varying the second group. The results could be displayed graphically as

shown in the figure.

If we had done a linear

analysis (no nonlinear geometric effects) the curves would be straight lines.

There is often more than one choice of dimensionless

group, and some are better than others.

For example, for the beam problem we could create a new dimensionless

group by multiplying together the two groups in the function g this gives

This turns out to be a much better choice. In fact, if

we conducted a linear analysis we would find that the function h is independent

of . In this case the data would collapse onto a

single master-curve as shown in the figure.

Unfortunately, dimensional analysis alone will not

tell you the best dimensionless groups.

You have to use your physical intuition to identify them. For the beam example, you might remember that

E and I always appear as the product EI

in the governing equations so it makes sense to try to find dimensionless

groups that combine them in this way.

In other examples, you may see some physical significance of

combinations of variables (they might look like a kinetic energy, or a

pressure, for example) which might help you to choose the best set.

The beauty of using dimensional analysis to simplify

numerical simulations is that, unlike in experiments, you don’t need to guess

what variables influence the results.

You know exactly what they are, because you typed them into the program!

The following steps (known as the Buckingham Pi

theorem) will tell you how many dimensionless groups to look for:

1. List the variable you are computing, and also the

variables you entered into the code to define the problem. Count the total number of variables and call

it n

2. List the dimensions, in terms of fundamental units

(i.e. mass, length, time, electric current, and luminous intensity) of all the

variables

3. Count the number of independent fundamental units that appear in the problem (e.g. if

mass, length and time appear independently, then there are 3 different units)

and call the number k. Units are independent if they don’t always

appear in the same combination. For

example, in our beam problem mass and time are not independent, because they appear together as in both P

and E. The beam problem has length, and as two independent combinations of fundamental

units.

4. A total of n-k

independent dimensionless groups must appear in the dimensionless relationship.

For the beam problem, we had 5 variables ,

and two independent combinations of fundamental units, so we expect to see

three dimensionless groups which is precisely what we got.

Simplifying

FEA analysis by scaling the

governing equations

Simplifying

FEA analysis by scaling the

governing equations

An alternative approach to identifying the

dimensionless parameters that control the solution to a problem is to express

the governing equations themselves in dimensionless form. This is a much more powerful technique, but

is also somewhat more difficult to use.

An alternative approach to identifying the

dimensionless parameters that control the solution to a problem is to express

the governing equations themselves in dimensionless form. This is a much more powerful technique, but

is also somewhat more difficult to use.

We can illustrate the procedure using our beam problem

again. Let x measure distance along the beam, and let w denote its vertical deflection.

You may remember that linear Euler-Bernoulli beam theory gives the

following governing equation for w

(the

right hand side vanishes because no forces act on 0<x<L)

while the boundary conditions are

(If you don’t remember these it doesn’t matter it’s the scaling discussed below that’s

important).

We now re-write the equations so that they are

dimensionless. We aways start by

replacing all field variables (in this case w

and x) with dimensionless

quantities. In this case we could use .

Substituting gives

We now look and see if we can make further

simplifications. Our objective is to

remove as many material and geometric parameters from the equations as

possible, by defining new dimensionless field variables or introducing

dimensionless combinations of material or geometric variables. In this case, we see that if we define a new

dimensionless displacement W so that

substitute, and cancel as many terms as possible, the

governing equations become

In this form, the governing equations contain

absolutely no material or geometric parameters.

The solution for W must

therefore be independent of L,E,I or P.

We can solve the equation just once, and then work out the tip

deflection from the value of W at . Specifically,

This scaling procedure is the best way to simplify

numerical computations. It is more

difficult to apply than dimensional analysis, however, and it is possible

(although perhaps not a good idea) to run an FEA simulation of a problem where

you don’t actually know the governing equations! In this case you should just

use standard dimensional analysis to try to simplify the problem.

The principle objective of the displacement based

finite element method is to compute the displacement

field within a solid subjected to external forces.

The principle objective of the displacement based

finite element method is to compute the displacement

field within a solid subjected to external forces.

In addition, special types of finite element can be

used to model the overall behavior of a 3D solid, without needing to solve for

the full 3D fields inside the solid.

Examples are shell elements; plate elements; beam elements and truss

elements. These will be discussed in a

separate section below.

In addition, special types of finite element can be

used to model the overall behavior of a 3D solid, without needing to solve for

the full 3D fields inside the solid.

Examples are shell elements; plate elements; beam elements and truss

elements. These will be discussed in a

separate section below.![]() Plane

Stress Finite Element Mesh : A plane stress finite element mesh is used to

model a plate - like solid which is loaded in its own plane. The solid must have uniform thickness, and

the thickness must be much less than any representative cross sectional

dimension. A plane stress finite element

mesh for a thin plate containing a hole is shown in the figure to the right. Only on quadrant of the specimen is modeled,

since symmetry boundary conditions will be enforced during the analysis.

Plane

Stress Finite Element Mesh : A plane stress finite element mesh is used to

model a plate - like solid which is loaded in its own plane. The solid must have uniform thickness, and

the thickness must be much less than any representative cross sectional

dimension. A plane stress finite element

mesh for a thin plate containing a hole is shown in the figure to the right. Only on quadrant of the specimen is modeled,

since symmetry boundary conditions will be enforced during the analysis.![]()

Plane Strain finite element mesh : A

plane strain finite element mesh is used to model a long cylindrical solid that

is prevented from stretching parallel to its axis. For example, a plane strain finite element

mesh for a cylinder which is in contact with a rigid floor is shown in the

figure. Away from the ends of the

cylinder, we expect it to deform so that the out of plane component of

displacement . There is no need to solve for ,

therefore, so a two dimensional mesh is sufficient to calculate and .

Plane Strain finite element mesh : A

plane strain finite element mesh is used to model a long cylindrical solid that

is prevented from stretching parallel to its axis. For example, a plane strain finite element

mesh for a cylinder which is in contact with a rigid floor is shown in the

figure. Away from the ends of the

cylinder, we expect it to deform so that the out of plane component of

displacement . There is no need to solve for ,

therefore, so a two dimensional mesh is sufficient to calculate and .![]()

Axisymmetric finite element mesh: An

axisymmetric mesh is used to model a solids that has rotational symmetry, which

is subjected to axisymmetric loading. An

example is shown on the right.

Axisymmetric finite element mesh: An

axisymmetric mesh is used to model a solids that has rotational symmetry, which

is subjected to axisymmetric loading. An

example is shown on the right. A finite element mesh is defined by a set of nodes together with a set of finite elements, as shown in the sketch on

the right.

A finite element mesh is defined by a set of nodes together with a set of finite elements, as shown in the sketch on

the right.![]() Nodes: The

nodes are a set of discrete points within the solid body. Nodes have the following properties:

Nodes: The

nodes are a set of discrete points within the solid body. Nodes have the following properties:![]() Elements

are used to partition the solid into discrete regions. Elements have the following properties.

Elements

are used to partition the solid into discrete regions. Elements have the following properties.

2.2.2 Special

Elements Beams, Plates, Shells and Truss elements

2.2.2 Special

Elements Beams, Plates, Shells and Truss elements For a plate, or shell, we again calculate the displacement and rotation of the plate

section. A three dimensional plate or shell has 3 displacement and two rotational degrees of freedom at

each node (these rotations characterize the rotation of a unit vector normal to

the plate). In some finite element

codes, nodes on plates and shells have a fictitious third rotational degree of

freedom which is added for convenience but you will find that attempting to impose

boundary conditions on this fictitious degree of freedom has no effect on the

deformation of the structure.

For a plate, or shell, we again calculate the displacement and rotation of the plate

section. A three dimensional plate or shell has 3 displacement and two rotational degrees of freedom at

each node (these rotations characterize the rotation of a unit vector normal to

the plate). In some finite element

codes, nodes on plates and shells have a fictitious third rotational degree of

freedom which is added for convenience but you will find that attempting to impose

boundary conditions on this fictitious degree of freedom has no effect on the

deformation of the structure. A good finite element code contains a huge library of

different types of material behavior that may be assigned to elements. A few examples are described below.

A good finite element code contains a huge library of

different types of material behavior that may be assigned to elements. A few examples are described below.![]() Linear

Elasticity. You should alreadly be

familiar with the idea of a linear elastic material. It has a uniaxial stressstrain response

(valid only for small strains) as shown in the picture

Linear

Elasticity. You should alreadly be

familiar with the idea of a linear elastic material. It has a uniaxial stressstrain response

(valid only for small strains) as shown in the picture ![]() , v=0.33, .

, v=0.33, .

![]() Elasticplastic material

behavior is usually used to model metals that are subjected to large

stresses, but there are also versions of plastic stress-strain laws that model

soils and concrete.

Elasticplastic material

behavior is usually used to model metals that are subjected to large

stresses, but there are also versions of plastic stress-strain laws that model

soils and concrete.![]() Hyperelasticity

is intended to model rubbery materials (or elastomeric foams, like a sponge)

which have (i) a reversible stress-v-strain relation and (ii) the stress is

independent of strain rate or loading history.

They are intended to model large changes in shape of the material

(that’s what the ‘hyper’ refers to).

This means that the stress-v-strain relation has to be defined rather

carefully, because there are several choices of stress and strain measure (e.g.

we could use ‘true’ stress or ‘nominal’ stress; similarly we could use

‘engineering’ strain or ‘true’ strain).

Hyperelasticity

is intended to model rubbery materials (or elastomeric foams, like a sponge)

which have (i) a reversible stress-v-strain relation and (ii) the stress is

independent of strain rate or loading history.

They are intended to model large changes in shape of the material

(that’s what the ‘hyper’ refers to).

This means that the stress-v-strain relation has to be defined rather

carefully, because there are several choices of stress and strain measure (e.g.

we could use ‘true’ stress or ‘nominal’ stress; similarly we could use

‘engineering’ strain or ‘true’ strain).

The simplest hyperelastic material model is the

so-called ‘neo-Hookean’ material. This model

is intended to predict the behavior of rubbers, which resist volume changes,

but deform very easily when subjected to shear stress. It has two material properties: (i) a shear