Chapter 14

Modeling Failure

One

of the most important applications of solid mechanics is to design structures,

components or materials that are capable of withstanding cyclic or static

service loads. To do this, you need to

be able to predict the conditions necessary to cause failure. Materials and structures can fail in many

different ways, including by buckling, excessive plastic flow, fatigue and

fracture, wear, or corrosion. Calculating

the stresses in a structure or component can help to design against these

failures, but is usually not enough it is also necessary to understand and to be

able to predict the effects of

stress.

In

this section we will discuss

- Failure by elastic buckling

- A brief review of the mechanisms of failure and

fatigue;

- An overview of phenomenological stress or strain

based failure criteria, primarily used in design applications;

- A brief discussion of the mechanics of cracks in

solids.

14.1 Failure by geometric instability in

elastic solids buckling

Components and structures that

are subjected to compressive loading can fail by buckling. Buckling is a form of instability that

involves a form of feedback: the loads applied to a solid cause it to deform;

if you are unlucky, the solid deforms in a way that causes the internal

stresses to increase, leading to further deformation, and this process may

continue without limit and cause complete collapse.

Simple illustration of the physics of buckling instability

The general nature of buckling

instability can be illustrated with a very simple example. The figure shows a column subjected to axial

loads. We could try to estimate its deformed

shape using the Rayleigh-Ritz method: guess the shape, and then minimize the

potential energy. Following the standard recipe:

1.

We guess that the beam bends into a circle with radius R (it is actually preferable to do the

calculation by solving for the curvature )

2.

The potential energy is

where is the deflection of the end

3.

Simple geometry shows that

4.

We can combine 2 and 3 to get the following expression

for a dimensionless potential energy

5.

Now we can minimize the potential energy with respect

to . We can do this graphically: the plot below

shows the variation of normalized potential energy with for several different values of

The important

conclusion from this plot is that if is below about 10, then the energy is

minimized with zero curvature (the beam is straight); but if exceeds 10, the energy is minimized with

nonzero curvature. The decrease in

potential energy of the applied loads is greater than the increase in strain

energy of the beam. Note that the

straight beam is still an equilibrium configuration but (because the energy is a maximum not a

minimum) equilibrium is unstable, and a small perturbation will cause it to

buckle into a curved shape.

It’s not hard

to calculate the curvature that minimizes the energy: the result is plotted

below

The plot shows

a ‘pitchfork bifurcation’ at . This

is a Rayleigh-Ritz estimate, of course, which will over-estimate the buckling

load. The exact calculation shows that buckling

occurs at ,

but the Rayleigh-Ritz solution is pretty good.

Calculating Buckling Loads

Calculating Buckling Loads

We can show how to calculate

buckling loads using a simple example. The

figure shows a straight column with Youngs modulus E, area moment of inertia and length L

subjected to axial forces P. Our goal is to calculate the critical value

of P that will cause buckling.

We already know the equations

governing small transverse deflections of a beam under significant axial force:

The axial force in the rod is

constant and equal to P, and we are

looking for static equilibrium solutions with non-zero . The

equilibrium equation therefore simplifies to

This equation has general

solution

The solution must satisfy the

governing equation, which shows that

Nonzero solutions require that .

Finally, the solution must

satisfy zero deflection and zero bending moment at and . This

means that

This shows that B=C=D=0. For nonzero A we must choose - this

gives us the so-called family of ‘buckling modes’, with

Each mode has a corresponding

value of axial force that will just hold it in place. The one with the lowest forces is n=1, which gives the famous Euler

buckling load

To summarize the general

procedure:

(1) Find

the equilibrium equation for your structure with a small deflection, and

significant axial force;

(2) The

equilibrium equations will have nonzero solutions satisfying the boundary

conditions for special values of the axial force; these will give the buckling

load.

Calculating Buckling Loads with ABAQUS

1.

Set up geometry, properties, section, etc in usual way.

2.

Create part instance in assembly in usual way

3.

Create a new step after optional static step, then in the

Step menu, select a ‘Linear Perturbation’ procedure, and select ‘Buckle’. You can select the number of buckling modes

you would like to extract.

4.

Apply boundary conditions in usual way. Be sure to include a load that will cause

buckling. The load can have an

arbitrary magnitude ABAQUS will compute how much the load needs to

be multiplied by to cause buckling.

5.

Mesh the solid be careful with element choice (usually best

to avoid reduced integration/incompatible modes as they have artificial

deformation modes; also if elements will lock that will cause serious

problems). If you want to extract a large

number of buckling modes you will need a fine mesh.

6.

Run job in usual way

7.

Buckling mode shapes can be displayed in Visualization

Module. The ‘Eigenvalue’ reported in the viewport is the scale factor applied

to the loads to just reach the buckling condition.

14.2 Summary of mechanisms of fracture and

fatigue under static and cyclic loading

Before

discussing the various approaches to modeling fracture, fatigue and failure, it

is helpful to review briefly the features and mechanisms of failure in solids.

Failure under monotonic loading

If you test a sample of any

material under uniaxial tension it will eventually fail. The features of the failure depend on several

factors, including

The materials involved and their

microsctructure;

The materials involved and their

microsctructure;

The applied stress state (particularly the

hydrostatic stress)

The applied stress state (particularly the

hydrostatic stress)

Loading rate

Loading rate

Temperature

Temperature

Ambient environment (water vapor; or presence

of corrosive environments).

Ambient environment (water vapor; or presence

of corrosive environments).

Materials

are normally classified loosely as either `brittle’ or `ductile’ depending on the characteristic

features of the failure.

Examples

of `brittle’ materials include refractory oxides (ceramics) and intermetallics,

as well as BCC metals at low temperature (below about of the melting point). Features of a brittle material are

- Very little plastic

flow occurs in the specimen prior to failure;

- The two sides of the

fracture surface fit together very well after failure.

- The fracture surface

appears faceted you can make out individual grains and

atomic planes.

- In many materials, fracture occurs along

certain crystallographic planes. In

other materials, fracture occurs along grain boundaries

Examples

of `ductile’ materials include FCC metals at all temperatures; BCC metals at

high temperatures; polymers at high temperature. Features of a `ductile’ fracture are

- Extensive plastic flow occurs in the material

prior to fracture

- There is usually evidence of considerable necking

in the specimen

- Fracture surfaces don’t fit together.

- The fracture surface

has a dimpled appearance you can see little holes, often with

second phase particles inside them.

Of

course, some materials (especially composites) have such a complex

microstructure that it’s hard to classify them as entirely brittle or entirely

ductile.

Brittle

fracture often occurs as a result of a single crack propagating through the

specimen. Some materials contain

pre-existing cracks, in which case fracture is initiated when one of these

cracks in a region of high tensile stress starts to grow. In other materials, the origin of the

fracture is less clear various mechanisms for nucleating crack have

been suggested, including dislocation pile-up at grain boundaries; or

intersections of dislocations.

Ductile

fracture occurs as a result of the nucleation, growth and coalescence of voids

in the material. Failure is controlled

by the rate of nucleation of the voids; their rate of growth, and the mechanism

of coalescence. High tensile hydrostatic

stress promotes rapid void nucleation and growth, but void growth generally also

requires significant bulk plastic strain.

A

ductile material may also fail as a result of plastic instability such as necking, or the formation of a shear

band. This is analogous to buckling at a critical strain, the component no longer

deforms uniformly, and the deformation localizes to a small region of

the solid. This is normally accompanied

by a loss of load bearing capacity and a large increase in plastic strain rate

in the localized region, which eventually causes failure.

Finally,

some materials, especially brittle materials such as glasses, and oxide based

ceramics, suffer from a form of time-delayed failure under steady loading,

known as `static fatigue’. Automatic coffee-maker jugs are particularly

susceptible to static fatigue. You use

one for a couple of years, and then one day it shatters if you tap it against

the side of the sink. This is because

the jug’s strength has degraded with time.

Static fatigue in brittle materials is a consequence of corrosion crack

growth. The highly stressed material

near a crack tip is particularly susceptible to chemical attack (the stress

increases the rate of chemical reaction).

Material near the crack tip may be dissolved altogether, or it may form

a reaction product with very low strength.

In either event, the crack slowly propagates through the solid, until it

becomes long enough to trigger brittle fracture. Glasses and oxide based

ceramics are particularly susceptible to attack by water-vapor (and perhaps

coffee).

Failure under cyclic loading

Mechanical engineers

generally have to design components to withstand cyclic as opposed to

static loading. Under cyclic loading,

materials fail by fatigue. Fatigue

failure is a familiar phenomenon, but a detailed understanding of the

mechanisms involved and the ability to model them quantitatively have only

emerged in the past 50 years, driven largely by the demands of the aerospace

industry. There are some forms of

fatigue failure (contact fatigue is an example) where the mechanisms involved

are still a mystery.

Fatigue life is measured by subjecting the material to

cyclic loading. The loading is usually uniaxial tension, but other cycles such

as torsion or bending can be used as well. The cycle can be stress controlled

(subjecting the material to a prescribed stress), or strain controlled. A cyclic

uniaxial stress is usually characterized by

Fatigue life is measured by subjecting the material to

cyclic loading. The loading is usually uniaxial tension, but other cycles such

as torsion or bending can be used as well. The cycle can be stress controlled

(subjecting the material to a prescribed stress), or strain controlled. A cyclic

uniaxial stress is usually characterized by

The stress amplitude

The stress amplitude

The mean

stress

The mean

stress

The stress

ratio

The stress

ratio

A

rotating bending test is a particularly convenient way to subject a material to

a very large number of cycles in a short period of time. The shaft can easily be spun at 2000rpm,

allowing the material to be subjected to cycles in less than 100 hrs. Pulsating tension is more common in service

loading, but a servo-hydraulic tensile testing machine operating at 1Hz takes

nearly 4 months to complete cycles.

The

resistance of a material to cyclic loading is characterized by plotting an

`S-N’ curve showing the number of cycles to failure as a function of stress

amplitude. The characteristic features of an S-N curve are illustrated in the

sketch on the right.

1. The plot normally shows two different regimes of

behavior, depending on stress amplitude.

2. At high stress levels, the material deforms

plastically and fails rapidly. In this

regime the life of the specimen depends primarily on the plastic strain

amplitude, rather than the stress amplitude.

This is referred to as `low cycle fatigue’ behavior.

3. At lower stress levels life has a power law dependence

on stress this is referred to as `high cycle’ fatigue

behavior.

4. In some materials, there is a clear fatigue limit

if the stress amplitude lies below a certain

limit, the specimen remains intact forever.

In other materials there is no clear fatigue threshold. In this case, the stress amplitude at which

the material survives cycles is taken as the endurance limit

of the material. (The term `endurance’ appears to refer to the engineer doing

the testing, rather than the material)

Fatigue

life is sensitive to the mean stress, or R ratio, and tends to fall

rather rapidly as R increases. It

is also influenced by environment, and temperature, and can be very sensitive

to details such as the surface finish of the specimen.

A

tensile specimen that has failed by fatigue looks at first sight as though it might

have failed by brittle fracture. The

fracture surface is flat, and the two sides of the specimen fit together quite

well. In fact, for some time it was

thought that some bizarre metallurgical process was responsible for turning a

ductile material brittle under cyclic loading. (An engineer named Nevil Norway wrote a

successful novel based on this theory.

The novel is entitled No Highway, published under the pseudonym Nevil

Shute). A closer examination reveals

several differences, however. You

usually don’t see cleavage planes on a fatigue surface, and instead often

observe a set of nearly parallel ridges on the surface, spaced at distances

between a few 100 angstroms to a few tenths of microns apart. These ridges are known as `striations’ and

are marks left behind by the tip of a fatigue crack at each cycle of load. In many materials, there is evidence for

local areas of cleavage fracture or void coalescence interspersed with the

striations.

Fatigue failures are caused by slow crack growth

through the material. The failure

process involves four stages

Fatigue failures are caused by slow crack growth

through the material. The failure

process involves four stages

1.

Crack initiation;

2. Micro-crack growth (with crack length less than the materials

grain size) (Stage I);

3. Macro crack growth (crack length between 0.1mm and

10mm) (Stage II);

4.

Failure by fast

fracture.

Cracks

will generally only initiate in the presence of cyclic plasticity. However, bulk plastic flow in the

specimen is not necessary: plastic flow may be caused by local stress

concentrations at notches in the part, due to geometric defects such as dents

or scratches in the surface, or even due to microstructural features such as

large inclusions in the material. In a smooth, clean specimen, the cracks form

where `persistent slip bands’ reach the surface of the specimen. Plastic flow in a material is generally

highly inhomogeneous at the micron scale, with the deformation confined to

narrow localized bands of slip. Where these bands intersect the surface,

intrusions or extrusions form, which serve as nucleation sites for cracks.

Cracks

initially propagate along the slip bands at around 45 degrees to the principal

stress direction this is known as Stage I fatigue crack growth. When the cracks reach a length comparable to

the materials grain size, they change direction and propagate perpendicular to

the principal stress. This is known as

Stage II fatigue crack growth.

14.3 Stress based fracture criteria for

brittle materials

Many

of the most successful design procedures use simple, experimentally calibrated,

functions of stress and strain to assess the likelihood of failure in a

component. Some examples of commonly

used failure criteria are summarized in this section.

Stress based failure criteria for

brittle solids and composites.

Experiments

show that brittle solids (such as ceramics, glasses, and fiber-reinforced

composites) tend to fail when the stress in the solid reaches a critical

magnitude. Materials such as ceramics

and glasses can be idealized using an isotropic

failure criterion. Composite materials

are stronger when loaded in some directions than others, and must be modeled

using an anisotropic failure

criterion.

Failure

criteria for isotropic materials

Failure

criteria for isotropic materials

The

simplest brittle fracture criterion states that fracture is initiated when the

greatest tensile principal stress in the solid reaches a critical magnitude,

(The subscript TS stands for

tensile strength). To apply the

criterion, you must

1. Measure (or look up) for the material. can be measured by conducting tensile tests on

specimens it is important to test a large number of

specimens because the failure stress is likely to show a great deal of

statistical scatter. The tensile

strength can also be measured using beam bending tests. The failure stress measured in a bending test

is referred to as the `modulus of rupture’ for the material. It is nominally equivalent to but in practice usually turns out to be

somewhat higher.

2. Calculate the anticipated stress distribution in your

component or structure (e.g. using FEM).

Finally, you plot contours of principal stress, and find the maximum

value . If the design is safe (but be sure to use an

appropriate factor of safety!).

Failure

criteria for anisotropic materials

Failure

criteria for anisotropic materials

More

sophisticated criteria must be used to model anisotropic materials (especially

composites). The criteria must take

account for the fact that the material is stronger in some directions than

others. For example, a fiber reinforced

composite is usually much stronger when loaded parallel to the fiber direction

than when loaded transverse to the fibers.

There are many different ways to account for this anisotropy a few approaches are summarized below.

Orientation

dependent fracture strength. One approach is to make the tensile strength

of the solid orientation dependent. For

example, the tensile strength of a brittle, orthotropic solid (with three

distinct, mutually perpendicular characteristic material directions) could be

characterized by its tensile strengths parallel to the three characteristic

directions in the solid.

The tensile strength when loaded

parallel to a general direction could be interpolated between these values as

Orientation

dependent fracture strength. One approach is to make the tensile strength

of the solid orientation dependent. For

example, the tensile strength of a brittle, orthotropic solid (with three

distinct, mutually perpendicular characteristic material directions) could be

characterized by its tensile strengths parallel to the three characteristic

directions in the solid.

The tensile strength when loaded

parallel to a general direction could be interpolated between these values as

where

are illustrated in the figure. The material fails if the stress acting

normal to any plane in the solid exceeds the fracture stress for that plane,

i.e.

where

are the stress components in the basis . To use this criterion to check for failure at

any point in the solid, you must

(i) Find the components of stress in the basis;

(ii) Maximize the function with respect to ;

and

(iii) Check whether the maximum value of exceeds 1.

If so, the material will fail; if not, it is safe.

Goldenblat-Kopnov failure criterion. A very general phenomenological failure criterion can

be constructed by simply combining the stress components in a basis oriented

with respect to material axes as polynomial function. The Goldenblat-Kopnov

criterion is one example, which states that the critical stresses required to

cause failure satisfy the equation

Here

A and B are material constants: A

is diagonal ( ) and has the same symmetries as the elasticity

tensor, i.e. . The most general anisotropic material would

therefore be characterized by 24 independent material constants, but in

practice simplified versions have far fewer parameters. Most failure criteria for composites are in

fact special cases of the Goldenblat-Kopnov criterion, including the Tsai-Hill

criterion outlined below.

Tsai-Hill

criterion: The Tsai-Hill criterion is used to model

damage in brittle laminated fiber-reinforced composites and wood. A specimen of

laminated composite subjected to in-plane loading is sketched in the

figure. The Tsai-Hill criterion assumes

that a plane stress state exists in the solid.

Let denote the nonzero components of stress, with

basis vectors and oriented parallel and perpendicular to the

fibers in the sheet, as shown. The

Tsai-Hill failure criterion is

Tsai-Hill

criterion: The Tsai-Hill criterion is used to model

damage in brittle laminated fiber-reinforced composites and wood. A specimen of

laminated composite subjected to in-plane loading is sketched in the

figure. The Tsai-Hill criterion assumes

that a plane stress state exists in the solid.

Let denote the nonzero components of stress, with

basis vectors and oriented parallel and perpendicular to the

fibers in the sheet, as shown. The

Tsai-Hill failure criterion is

at

failure, where ,

and are material properties. They are measured as follows:

1.

The laminate is

loaded in uniaxial tension parallel to the fibers. The material fails when

2. The laminate is loaded in uniaxial tension perpendicular

to the fibers. The material fails

when

3. In principle, the laminate could be loaded in shear it would then fail when .

In practice it is preferable to pull on the laminate in uniaxial tension with

stress at 45 degrees to the fibers, which induces

stress components . A simple calculation then shows that .

Probabilistic Design

Methods for Brittle Fracture (Weibull

Statistics)

The

fracture criterion is too crude for many applications. The tensile strength of a brittle solid

usually shows considerable statistical scatter, because the likelihood of

failure is determined by the probability of finding a large flaw in a highly

stressed region of the material. This

makes it difficult to determine an unambiguous value for tensile strength should you use the median value of your

experimental data? Pick the stress level

where 95% of specimens survive? It’s better to deal with this problem using a

more rigorous statistical approach.

Weibull

statistics refers to a technique used to predict the probability of failure in

a brittle material. The following

approach is used

1. Test a large number of samples with identical size and

shape under uniform tensile stress, and determine their survival probability as

a function of stress (survival probability is approximated by the fraction of

specimens that survive a given stress level).

2. Fit the survival probability of these specimens is fit by a Weibull distribution

where and m are material constants. The index m is typically of the order

5-10 for ceramics, and is independent of specimen volume. The parameter is the stress at which the probability of

survival is exp(-1), (about 37%). This critical stress depends on the specimen volume ,

and is smaller for larger specimens.

3. Given m, and the corresponding specimen volume ,

the survival probability of a volume of material subjected to uniform uniaxial

stress follows as

To see this, note that the volume V can be

thought of as containing specimens.

The probability that they all survive is .

4. More generally, the survival probability of a solid

subjected to an arbitrary stress distribution with principal values can be computed as

where

This

approach is quite successful in some applications: for example, it explains why

brittle materials appear to be stronger in bending than in uniaxial

tension. Like many statistical

approaches it has some limitations as a design tool. The method can predict accurately the stress

that gives 30% probability of failure.

But who wants to buy a product that has a 30% probability of

failure? For design applications we need

to predict the probability of 1 failure in a million or so. It is very difficult to measure the tail

of a statistical distribution accurately, and a distribution that was fit to

predict 63% failure probability may be wildly inaccurate in the region of

interest.

14.4 Strain Based Ductile Failure

Criteria

Strain

to failure approach: Ductile

fracture in tension occurs by the nucleation, growth and coalescence of voids

in the material. A crude criterion for

ductile failure could be based on the accumulated plastic strain, for example

at failure, where is the plastic strain to failure in a uniaxial

tensile test.

Porous metal plasticity: Experiments show that the strain to cause ductile

failure in a material depends on the hydrostatic component of tensile stress

acting on the specimen, as shown in the figure.

For example, the strain to failure under torsional loading (which

subjects the material to shear with no hydrostatic stress) is much greater than

under uniaxial tension. The critical strain is influenced by hydrostatic stress

because ductile failure occurs as a result of the nucleation and growth of

cavities in the solid. A hydrostatic

stress greatly increases the rate of growth of the cavities. The simple

strain-to-failure approach cannot account for this behavior.

Porous metal plasticity: Experiments show that the strain to cause ductile

failure in a material depends on the hydrostatic component of tensile stress

acting on the specimen, as shown in the figure.

For example, the strain to failure under torsional loading (which

subjects the material to shear with no hydrostatic stress) is much greater than

under uniaxial tension. The critical strain is influenced by hydrostatic stress

because ductile failure occurs as a result of the nucleation and growth of

cavities in the solid. A hydrostatic

stress greatly increases the rate of growth of the cavities. The simple

strain-to-failure approach cannot account for this behavior.

Porous metal

plasticity was developed to address this issue.

The basic idea is simple: the solid is idealized as a plastic matrix

which contains a volume fraction of cavities.

To model the solid, the plastic stress-strain laws outlined in Sections 3.6

and 3.7 are extended to calculate the volume fraction of voids in the material

as part of the solution, and also to account for the weakening effect of the

voids. Failure is modeled by

constructing the plastic stress-strain law so that the material loses all its

strength at a critical void volume fraction.

Both

rate independent and viscoplastic versions of porous plasticity exist. The viscoplastic models have some advantages

for finite element computations, because the rate dependence can stabilize the

effects of strain softening. A simple

small-strain viscoplastic constitutive law with power-law hardening and

power-law rate dependence will be outlined here to illustrate the main features

of these models. The constitutive law is

known as the `Gurson model.’

The

material is characterized by the following properties:

The

Young’s modulus E and Poisson ratio ;

The

Young’s modulus E and Poisson ratio ;

A

characteristic stress Y, a

characteristic strain and

strain hardening exponent n, which

govern the strain hardening behavior of the matrix material;

A

characteristic stress Y, a

characteristic strain and

strain hardening exponent n, which

govern the strain hardening behavior of the matrix material;

A

characteristic strain rate and strain rate exponent m, which govern the strain rate sensitivity of the solid;

A

characteristic strain rate and strain rate exponent m, which govern the strain rate sensitivity of the solid;

A

constant ,

which controls the rate of void nucleation with plastic straining;

A

constant ,

which controls the rate of void nucleation with plastic straining;

The flow

strength of the matrix ,

the void volume fraction, ,

and the total accumulated effective plastic strain in the matrix material which all evolve with plastic straining.

The flow

strength of the matrix ,

the void volume fraction, ,

and the total accumulated effective plastic strain in the matrix material which all evolve with plastic straining.

The

constitutive equations specify a relationship between the stress applied to the material and the resulting

strain rate ,

as follows

1.

The strain rate

is decomposed into elastic and plastic parts as ;

2.

The elastic part

of the strain rate is related to the stress rate by the linear elastic

constitutive equations

3. The magnitude of the plastic strain rate is determined

by the following plastic flow potential

where ,

and . Note that for the plastic strain rate increases with

hydrostatic stress p.

4.

The components of the

plastic strain rate tensor are computed from an associated flow law

5. Strain hardening in the matrix is modeled by relating

its flow stress to the accumulated strain in the matrix .

The following power-law hardening model is often used

6. The effective plastic strain in the matrix is

calculated from the condition that the plastic dissipation in the matrix must

equal the rate of work done by stresses, which requires that

7. Finally, the model is completed by specifying the void

volume fraction as a function of strain.

The void volume fraction can increase due to growth of existing voids,

or nucleation of new ones. To account for both effects, one can set

where the first term accounts for void growth, and the

second accounts for strain controlled void nucleation.

Ductile failure by strain

localization

If you test a cylindrical specimen of a very ductile

material in uniaxial tension, it will initially deform uniformly, and remain

cylindrical. At a critical load (or strain) the specimen will start to neck, as

shown in the picture. Necking, once it

starts, is usually unstable there is a concentration in stress near the

necked region, increasing the rate of plastic flow near the neck compared with

the rest of the specimen, and so increasing the rate of neck formation. The strains in the necked region rapidly

become very large, and quickly lead to failure.

If you test a cylindrical specimen of a very ductile

material in uniaxial tension, it will initially deform uniformly, and remain

cylindrical. At a critical load (or strain) the specimen will start to neck, as

shown in the picture. Necking, once it

starts, is usually unstable there is a concentration in stress near the

necked region, increasing the rate of plastic flow near the neck compared with

the rest of the specimen, and so increasing the rate of neck formation. The strains in the necked region rapidly

become very large, and quickly lead to failure.

Neck

formation is a consequence of geometric softening. A very simple model explains the concept of

geometric softening.

1. Consider a cylindrical specimen with initial cross

sectional area and

length .

The specimen is subjected to a load P, which deforms the material

plastically. After straining, the length of the specimen increases to L,

and its cross-sectional area decreases to A.

2. Assume that the material is perfectly plastic and has

a true stress-strain curve (Cauchy stress v- logarithmic

strain) that can be approximated by a power-law with n<1.

3. The true strain in the specimen is related to its

length by

4. The force on the specimen is related to the Cauchy

stress by

5. At the point of maximum load

6. We can calculate by noting that the volume of the specimen is

constant during plastic straining, which shows that

Notice

that is negative this means that the specimen tends to soften

as a result of the change in its cross sectional area. This is what is meant by geometric softening.

7.

We can calculate from (2) and (3) as follows

Notice

that is positive strain hardening in the material tends to

compensate for the effects of geometric softening.

8.

Finally,

substituting the results of (6) and (7) back into (5) and recalling that shows that at the point of maximum load, the

strain and length of the specimen are

9.

Finally, note

that by volume conservation the cross sectional area is ,

so the maximum load the specimen can withstand follows as

It

turns out that the point of maximum load coincides with the condition for

unstable neck formation in the bar. This

is plausible a falling load displacement curve is always a

sign that there might be a possibility of non-unique solutions but a rather sophisticated calculation is

required to show this rigorously.

There are two important

points to take away from this discussion.

Plastic localization, as opposed to material

failure, may limit load bearing capacity;

Plastic localization, as opposed to material

failure, may limit load bearing capacity;

If you measure the strain to failure of a

material in uniaxial tension, it is possible that you have not measured the

inherent strength of the material your specimen may have failed due to a

geometric effect. Material behavior does

influence the strain to failure, of course: the simple analysis of geometric

softening shows that the strain hardening behavior of the material is

critical.

If you measure the strain to failure of a

material in uniaxial tension, it is possible that you have not measured the

inherent strength of the material your specimen may have failed due to a

geometric effect. Material behavior does

influence the strain to failure, of course: the simple analysis of geometric

softening shows that the strain hardening behavior of the material is

critical.

Plastic localization can occur for many reasons. There are two general classes of localization

it may occur as a consequence of changes in

specimen geometry (i.e. geometric softening); or it may occur due to a natural

tendency of the material itself to soften at large strains.

Examples

of geometry induced localization are

1.

Neck formation in

a bar under uniaxial tension;

2. Shear band formation in torsional or shear loading at

high strain rate due to thermal softening as a result of plastic heat

generation

Examples of material

induced localization are

1. Localization in a Gurson solid due to the softening

effect of voids at large strains;

2. Localization in a single crystal due to the softening

effect of lattice rotations;

3. Localization in a brittle microcracking material due

to the increase in elastic compliance caused by the cracks.

Geometric

localization can be modeled quite easily, because it does not rely on any

empirical failure criteria. A

straightforward FEM computation, with an appropriate constitutive law and

proper consideration of finite strains, will predict localization if it is going

to occur the only thing you need to worry about is to

be sure you understand what triggered the localization. Localization can start at a geometric

imperfection in the model, in which case your prediction is meaningful (but may

be sensitive to the nature of the imperfection). It may also be triggered by numerical errors,

in which case the predicted failure load is meaningless. It is usually exceedingly difficult to

compute what happens after localization.

Fortunately it’s rather rare to need to do this for design purposes.

14.5 Criteria for Failure Under

Cyclic Loading

High cycle fatigue under constant amplitude cyclic loading

High cycle fatigue under constant amplitude cyclic loading

Empirical stress or strain

based life prediction methods are extensively used in design applications. The approach is straightforward subject a sample of the material to a cycle of

stress (or strain) that resembles service loading, in an environment

representative of service conditions, and measure its life as a function of

stress (or strain) amplitude, then fit the data with a curve.

Here

we will review criteria that are used to predict fatigue life under

proportional cyclic loading. A typical stress cycle is parameterized by its

amplitude and the mean stress

For

tests run in the high cycle fatigue regime with any fixed value of mean stress,

the relationship between stress amplitude and the number of cycles to failure N

is fit well by Basquin’s Law

where the exponent b

is typically between 0.05 and 0.15. The

constant C is a function of mean stress.

There

are two ways to account for the effects of mean stress. Both are based on the same idea: we know that

if the mean stress is equal to the tensile strength of the material ,

it will fail in 0 cycles of loading. We

also know that for zero mean stress, the fatigue life obeys Basquin’s law. We can interpolate between these two points. There are two ways to do this:

Goodman’s rule

uses a linear interpolation, giving

Goodman’s rule

uses a linear interpolation, giving

where

is the constant in Basquin’s law determined by

testing at zero mean stress.

Gerber’s rule

uses a parabolic fit

Gerber’s rule

uses a parabolic fit

In

practice, experimental data seem to lie between these two limits. Goodman’s rule gives a safe estimate.

These

criteria are intended to be used for components that are subjected to uniaxial

tensile stress. The criteria can still

be used if the loading is proportional

(i.e. with fixed directions of principal

stress). In this case, the maximum

principal stress should be used to calculate and . They do not work under non-proportional

loading. A very large number of fatigue

models have been developed for more general loading conditions a review can be found in Liu

and Mahadevan, Int J. Fatigue, 27

790-800 (2005).

Criteria for failure by low

cycle fatigue

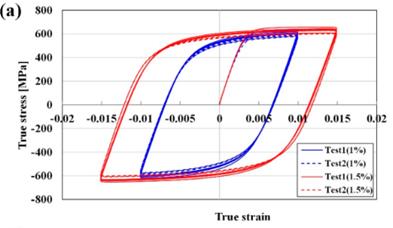

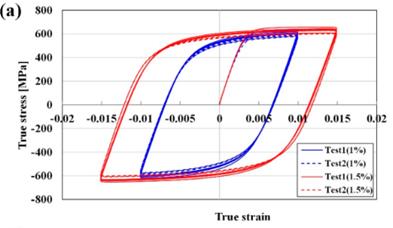

If a fatigue test is run with a high stress level

(sufficient to cause plastic flow in a large section of the solid) the specimen

fails very quickly (less than 10 000 cycles).

This regime of behavior is known as `low cycle fatigue’. The fatigue life correlates best with the

plastic strain amplitude rather than stress amplitude, and it is found that the

Coffin Manson Law

If a fatigue test is run with a high stress level

(sufficient to cause plastic flow in a large section of the solid) the specimen

fails very quickly (less than 10 000 cycles).

This regime of behavior is known as `low cycle fatigue’. The fatigue life correlates best with the

plastic strain amplitude rather than stress amplitude, and it is found that the

Coffin Manson Law

gives

a good fit to empirical data (the constants C and b do not have

the same values as for Basquin’s law, of course)

Calculating Buckling Loads

Calculating Buckling Loads

![]() The materials involved and their

microsctructure;

The materials involved and their

microsctructure;![]() The applied stress state (particularly the

hydrostatic stress)

The applied stress state (particularly the

hydrostatic stress)![]() Loading rate

Loading rate![]() Temperature

Temperature![]() Ambient environment (water vapor; or presence

of corrosive environments).

Ambient environment (water vapor; or presence

of corrosive environments). Fatigue life is measured by subjecting the material to

cyclic loading. The loading is usually uniaxial tension, but other cycles such

as torsion or bending can be used as well. The cycle can be stress controlled

(subjecting the material to a prescribed stress), or strain controlled. A cyclic

uniaxial stress is usually characterized by

Fatigue life is measured by subjecting the material to

cyclic loading. The loading is usually uniaxial tension, but other cycles such

as torsion or bending can be used as well. The cycle can be stress controlled

(subjecting the material to a prescribed stress), or strain controlled. A cyclic

uniaxial stress is usually characterized by![]() The stress amplitude

The stress amplitude ![]() The mean

stress

The mean

stress ![]() The stress

ratio

The stress

ratio

Fatigue failures are caused by slow crack growth

through the material. The failure

process involves four stages

Fatigue failures are caused by slow crack growth

through the material. The failure

process involves four stages![]() Failure

criteria for isotropic materials

Failure

criteria for isotropic materials ![]() Failure

criteria for anisotropic materials

Failure

criteria for anisotropic materials Orientation

dependent fracture strength. One approach is to make the tensile strength

of the solid orientation dependent. For

example, the tensile strength of a brittle, orthotropic solid (with three

distinct, mutually perpendicular characteristic material directions) could be

characterized by its tensile strengths parallel to the three characteristic

directions in the solid.

The tensile strength when loaded

parallel to a general direction could be interpolated between these values as

Orientation

dependent fracture strength. One approach is to make the tensile strength

of the solid orientation dependent. For

example, the tensile strength of a brittle, orthotropic solid (with three

distinct, mutually perpendicular characteristic material directions) could be

characterized by its tensile strengths parallel to the three characteristic

directions in the solid.

The tensile strength when loaded

parallel to a general direction could be interpolated between these values as Tsai-Hill

criterion: The Tsai-Hill criterion is used to model

damage in brittle laminated fiber-reinforced composites and wood. A specimen of

laminated composite subjected to in-plane loading is sketched in the

figure. The Tsai-Hill criterion assumes

that a plane stress state exists in the solid.

Let denote the nonzero components of stress, with

basis vectors and oriented parallel and perpendicular to the

fibers in the sheet, as shown. The

Tsai-Hill failure criterion is

Tsai-Hill

criterion: The Tsai-Hill criterion is used to model

damage in brittle laminated fiber-reinforced composites and wood. A specimen of

laminated composite subjected to in-plane loading is sketched in the

figure. The Tsai-Hill criterion assumes

that a plane stress state exists in the solid.

Let denote the nonzero components of stress, with

basis vectors and oriented parallel and perpendicular to the

fibers in the sheet, as shown. The

Tsai-Hill failure criterion is

Porous metal plasticity: Experiments show that the strain to cause ductile

failure in a material depends on the hydrostatic component of tensile stress

acting on the specimen, as shown in the figure.

For example, the strain to failure under torsional loading (which

subjects the material to shear with no hydrostatic stress) is much greater than

under uniaxial tension. The critical strain is influenced by hydrostatic stress

because ductile failure occurs as a result of the nucleation and growth of

cavities in the solid. A hydrostatic

stress greatly increases the rate of growth of the cavities. The simple

strain-to-failure approach cannot account for this behavior.

Porous metal plasticity: Experiments show that the strain to cause ductile

failure in a material depends on the hydrostatic component of tensile stress

acting on the specimen, as shown in the figure.

For example, the strain to failure under torsional loading (which

subjects the material to shear with no hydrostatic stress) is much greater than

under uniaxial tension. The critical strain is influenced by hydrostatic stress

because ductile failure occurs as a result of the nucleation and growth of

cavities in the solid. A hydrostatic

stress greatly increases the rate of growth of the cavities. The simple

strain-to-failure approach cannot account for this behavior.![]() The

Young’s modulus E and Poisson ratio ;

The

Young’s modulus E and Poisson ratio ;![]() A

characteristic stress Y, a

characteristic strain and

strain hardening exponent n, which

govern the strain hardening behavior of the matrix material;

A

characteristic stress Y, a

characteristic strain and

strain hardening exponent n, which

govern the strain hardening behavior of the matrix material;![]() A

characteristic strain rate and strain rate exponent m, which govern the strain rate sensitivity of the solid;

A

characteristic strain rate and strain rate exponent m, which govern the strain rate sensitivity of the solid;![]() A

constant ,

which controls the rate of void nucleation with plastic straining;

A

constant ,

which controls the rate of void nucleation with plastic straining;![]() The flow

strength of the matrix ,

the void volume fraction, ,

and the total accumulated effective plastic strain in the matrix material which all evolve with plastic straining.

The flow

strength of the matrix ,

the void volume fraction, ,

and the total accumulated effective plastic strain in the matrix material which all evolve with plastic straining. If you test a cylindrical specimen of a very ductile

material in uniaxial tension, it will initially deform uniformly, and remain

cylindrical. At a critical load (or strain) the specimen will start to neck, as

shown in the picture. Necking, once it

starts, is usually unstable there is a concentration in stress near the

necked region, increasing the rate of plastic flow near the neck compared with

the rest of the specimen, and so increasing the rate of neck formation. The strains in the necked region rapidly

become very large, and quickly lead to failure.

If you test a cylindrical specimen of a very ductile

material in uniaxial tension, it will initially deform uniformly, and remain

cylindrical. At a critical load (or strain) the specimen will start to neck, as

shown in the picture. Necking, once it

starts, is usually unstable there is a concentration in stress near the

necked region, increasing the rate of plastic flow near the neck compared with

the rest of the specimen, and so increasing the rate of neck formation. The strains in the necked region rapidly

become very large, and quickly lead to failure.![]() Plastic localization, as opposed to material

failure, may limit load bearing capacity;

Plastic localization, as opposed to material

failure, may limit load bearing capacity;![]() If you measure the strain to failure of a

material in uniaxial tension, it is possible that you have not measured the

inherent strength of the material your specimen may have failed due to a

geometric effect. Material behavior does

influence the strain to failure, of course: the simple analysis of geometric

softening shows that the strain hardening behavior of the material is

critical.

If you measure the strain to failure of a

material in uniaxial tension, it is possible that you have not measured the

inherent strength of the material your specimen may have failed due to a

geometric effect. Material behavior does

influence the strain to failure, of course: the simple analysis of geometric

softening shows that the strain hardening behavior of the material is

critical.  High cycle fatigue under constant amplitude cyclic loading

High cycle fatigue under constant amplitude cyclic loading![]() Goodman’s rule

uses a linear interpolation, giving

Goodman’s rule

uses a linear interpolation, giving![]() Gerber’s rule

uses a parabolic fit

Gerber’s rule

uses a parabolic fit If a fatigue test is run with a high stress level

(sufficient to cause plastic flow in a large section of the solid) the specimen

fails very quickly (less than 10 000 cycles).

This regime of behavior is known as `low cycle fatigue’. The fatigue life correlates best with the

plastic strain amplitude rather than stress amplitude, and it is found that the

Coffin Manson Law

If a fatigue test is run with a high stress level

(sufficient to cause plastic flow in a large section of the solid) the specimen

fails very quickly (less than 10 000 cycles).

This regime of behavior is known as `low cycle fatigue’. The fatigue life correlates best with the

plastic strain amplitude rather than stress amplitude, and it is found that the

Coffin Manson Law