Chapter 2

Review of Forces and Moments

2.1 Forces

In

this chapter we review the basic concepts of forces, and force laws. Most of this material is identical to

material covered in EN030, and is provided here as a review. There are a few

additional sections for example forces exerted by a damper or dashpot, an inerter, and interatomic forces are discussed in

Section 2.1.7.

2.1.1 Definition of a force

Engineering

design calculations nearly always use classical (Newtonian) mechanics. In

classical mechanics, the concept of a `force’ is based on experimental

observations that everything in the universe seems to have a preferred

configuration masses appear to attract each other; objects

with opposite charges attract one another; magnets can repel or attract one

another; you are probably repelled by your professor. But we don’t really know why this is

(except perhaps the last one).

The

idea of a force is introduced to quantify the tendency of objects to

move towards their preferred configuration.

If objects accelerate very quickly towards their preferred

configuration, then we say that there’s a big force acting on them. If they

don’t move (or move at constant velocity), then there is no force. We can’t see

a force; we can only deduce its existence by observing its effect.

Specifically, forces are

defined through Newton’s

laws of motion

0. A `particle’ is a small mass at some position in space.

0. A `particle’ is a small mass at some position in space.

1.

When the sum of the forces acting on a particle is zero, its velocity is

constant;

2.

The sum of forces acting on a particle of constant mass is equal to the product

of the mass of the particle and its acceleration;

3.

The forces exerted by two particles on each other are equal in magnitude and

opposite in direction.

Isaac Newton on a bad hair day

The second law provides the

definition of a force if a mass m has acceleration a,

the force F acting on it is

Of course, there is a big

problem with Newton’s

laws what do we take as a fixed point (and

orientation) in order to define acceleration?

The general theory of relativity addresses this issue rigorously. But for engineering calculations we can

usually take the earth to be fixed, and happily apply Newton’s laws. In rare cases where the earth’s motion is

important, we take the stars far from the solar system to be fixed.

2.1.2 Causes of force

Forces may arise from a

number of different effects, including

(i)

Gravity;

(ii)

Electromagnetism or electrostatics;

(iii)

Pressure exerted by fluid or gas on part of a structure

(v)

Wind or fluid induced drag or lift forces;

(vi)

Contact forces, which act wherever a structure or component touches anything;

(vii)

Friction forces, which also act at contacts.

Some

of these forces can be described by universal laws. For example, gravity forces can be calculated

using Newton’s

law of gravitation; electrostatic forces acting between charged particles are

governed by Coulomb’s law; electromagnetic forces acting between current

carrying wires are governed by Ampere’s law; buoyancy forces are governed by

laws describing hydrostatic forces in fluids. Some of these universal force laws are listed

in Section 2.6.

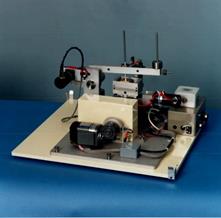

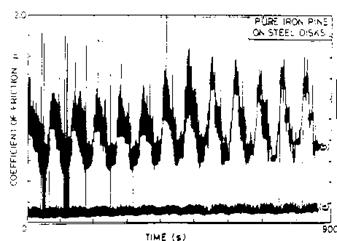

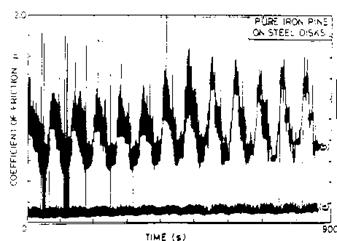

Some

forces have to be measured. For example, to determine friction forces acting in

a machine, you may need to measure the coefficient of friction for the

contacting surfaces. Similarly, to

determine aerodynamic lift or drag forces acting on a structure, you would

probably need to measure its lift and drag coefficient experimentally. Lift and drag forces are described in Section

2.6. Friction forces are discussed in

Section 12.

Contact

forces are pressures that act on the

small area of contact between two objects.

Contact forces can either be measured, or they can be calculated by

analyzing forces and deformation in the system of interest. Contact forces are very complicated, and are

discussed in more detail in Section 8.

2.1.3 Units of force and

typical magnitudes

In SI units, the

standard unit of force is the Newton,

given the symbol N.

The Newton is a derived unit, defined

through Newton’s

second law of motion a force of 1N causes a 1 kg mass to accelerate

at 1 .

The fundamental unit of

force in the SI convention is kg m/s2

In US units, the

standard unit of force is the pound, given the symbol lb or lbf (the latter is

an abbreviation for pound force, to distinguish it from pounds weight)

A force of 1 lbf causes a

mass of 1 slug to accelerate at 1 ft/s2

US

units have a frightfully confusing way of representing mass often the mass of an object is reported as weight,

in lb or lbm (the latter is an abbreviation for pound mass). The weight of an object in lb is not mass at

all it’s actually the gravitational force acting on the mass. Therefore, the mass of an object in slugs

must be computed from its weight in pounds using the formula

where g=32.1740 ft/s2

is the acceleration due to gravity.

A force of 1 lb(f) causes a

mass of 1 lb(m) to accelerate at 32.1740 ft/s2

The conversion factors from

lb to N are

|

1 lb

|

=

|

4.448 N

|

|

1 N

|

=

|

0.2248 lb

|

(www.onlineconversion.com is a handy

resource, as long as you can tolerate all the hideous advertisements…)

As

a rough guide, a force of 1N is about equal to the weight of a medium sized

apple. A few typical force magnitudes (from `The Sizesaurus’, by Stephen

Strauss, Avon Books, NY, 1997) are listed in the table below

|

Force

|

Newtons

|

Pounds Force

|

|

Gravitational Pull of the

Sun on Earth

|

|

|

|

Gravitational Pull of the

Earth on the Moon

|

|

|

|

Thrust of a Saturn V

rocket engine

|

|

|

|

Thrust of a large jet

engine

|

|

|

|

Pull of a large

locomotive

|

|

|

|

Force between two protons

in a nucleus

|

|

|

|

Gravitational pull of the

earth on a person

|

|

|

|

Maximum force exerted

upwards by a forearm

|

|

|

|

Gravitational pull of the

earth on a 5 cent coin

|

|

|

|

Force between an electron

and the nucleus of a Hydrogen atom

|

|

|

2.1.4 Classification of

forces: External forces, constraint forces and internal forces.

When analyzing forces in a

structure or machine, it is conventional to classify forces as external

forces; constraint forces or internal forces.

External forces arise from interaction between the system of interest

and its surroundings.

Examples

of external forces include gravitational forces; lift or drag forces arising

from wind loading; electrostatic and electromagnetic forces; and buoyancy

forces; among others. Force laws

governing these effects are listed later in this section.

Constraint forces are exerted by one part of a structure on another, through joints,

connections or contacts between components.

Constraint forces are very complex, and will be discussed in detail in

Section 8.

Internal

forces are forces that act inside a

solid part of a structure or component.

For example, a stretched rope has a tension

force acting inside it, holding the rope together. Most solid objects contain very complex

distributions of internal force. These

internal forces ultimately lead to structural failure, and also cause the

structure to deform. The purpose of

calculating forces in a structure or component is usually to deduce the

internal forces, so as to be able to design stiff, lightweight and strong

components. We will not, unfortunately,

be able to develop a full theory of internal forces in this course a proper discussion requires understanding of

partial differential equations, as well as vector and tensor calculus. However, a brief discussion of internal

forces in slender members will be

provided in Section 9.

2.1.5 Mathematical

representation of a force.

Force is a vector it has a magnitude (specified in Newtons, or lbf, or

whatever), and a direction.

A force is therefore always

expressed mathematically as a vector quantity.

To do so, we follow the usual rules, which are described in more detail

in the vector tutorial. The procedure is

1.

Choose basis

vectors or that establish three fixed (and usually

perpendicular) directions in space;

2.

Using geometry or

trigonometry, calculate the force component along each of the three reference

directions or ;

3.

The vector force

is then reported as

For calculations, you will

also need to specify the point where the force acts on your system or

structure. To do this, you need to

report the position vector of the point where the force acts on the

structure.

The procedure for

representing a position vector is also described in detail in the vector

tutorial. To do so, you need to:

1.

Choose an origin

2.

Choose basis

vectors or that establish three fixed directions in space

(usually we use the same basis for both force and position vectors)

3.

Specify the

distance you need to travel along each direction to get from the origin to the

point of application of the force or

4.

The position

vector is then reported as

2.1.6 Measuring forces

Engineers

often need to measure forces. According to the definition, if we want to

measure a force, we need to get hold of a 1 kg mass, have the force act on it

somehow, and then measure the acceleration of the mass. The magnitude of the

acceleration tells us the magnitude of the force; the direction of motion of

the mass tells us the direction of the force.

Fortunately, there are easier ways to measure forces.

In addition to causing acceleration, forces

cause objects to deform for example, a force will stretch or compress

a spring; or bend a beam. The

deformation can be measured, and the force can be deduced.

The

simplest application of this phenomenon is a spring scale. The change in length of a spring is proportional

to the magnitude of the force causing it to stretch (so long as the force is

not too large!) this

relationship is known as Hooke’s law and can be expressed as an equation

where the spring stiffness depends on the material the spring is made

from, and the shape of the spring. The

spring stiffness can be measured experimentally to calibrate the spring.

Spring

scales are not exactly precision instruments, of course. But the same principle is used in more

sophisticated instruments too. Forces

can be measured precisely using a `force transducer’ or `load cell’ (A search

for `force transducer’ on any search engine will bring up a huge variety of

these a few are shown in the picture). The simplest load cell works much like a

spring scale you can load it in one direction, and it will

provide an electrical signal proportional to the magnitude of the force. Sophisticated load cells can measure a force vector,

and will record all three force components.

Really fancy load cells measure both force vectors, and torque or moment

vectors.

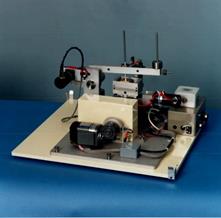

Simple force transducers capable of measuring a single

force component. The instrument on the

right is called a `proving ring’ there’s a short article describing how it

works at http://www.mel.nist.gov/div822/proving_ring.htm

A sophisticated force transducer produced by MTS

systems, which is capable of measuring forces and moments acting on a car’s

wheel in-situ. The spec for this

device can be downloaded at http://www.mts.com/cs/groups/public/documents/library/dev_002232.pdf

The basic design of all

these load cells is the same they measure (very precisely) the deformation

in a part of the cell that acts like a very stiff spring. One example (from Sandia National Lab

) is shown on the right. In this case

the `spring’ is actually a tubular piece of high-strength steel. When a force acts on the cylinder, its length

decreases slightly. The deformation is

detected using `strain gages’ attached to the cylinder. A strain gage is really

just a thin piece of wire, which deforms with the cylinder. When the wire gets shorter, its electrical

resistance decreases this resistance change can be measured, and

can be used to work out the force. It is

possible to derive a formula relating the force to the change in resistance,

the load cell geometry, and the material properties of steel, but the

calculations involved are well beyond the scope of this course.

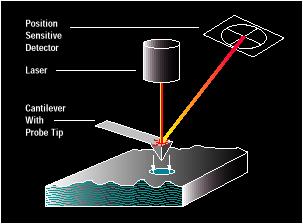

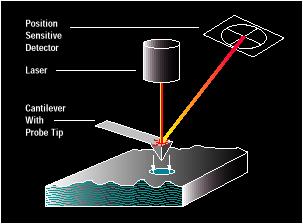

The most sensitive load cell currently available is

the atomic force microscope (AFM) which as the name suggests, is intended to

measure forces between small numbers of atoms.

This device consists of a very thin (about 1 ) cantilever beam, clamped at one end, with a

sharp tip mounted at the other. When the

tip is brought near a sample, atomic interactions exert a force on the tip and

cause the cantilever to bend. The

bending is detected by a laser-mirror system.

The device is capable of measuring forces of about 1 pN (that’s N!!), and is used to explore the properties of

surfaces, and biological materials such as DNA strands and cell membranes. A nice article on the AFM can be found at http://www.di.com

The most sensitive load cell currently available is

the atomic force microscope (AFM) which as the name suggests, is intended to

measure forces between small numbers of atoms.

This device consists of a very thin (about 1 ) cantilever beam, clamped at one end, with a

sharp tip mounted at the other. When the

tip is brought near a sample, atomic interactions exert a force on the tip and

cause the cantilever to bend. The

bending is detected by a laser-mirror system.

The device is capable of measuring forces of about 1 pN (that’s N!!), and is used to explore the properties of

surfaces, and biological materials such as DNA strands and cell membranes. A nice article on the AFM can be found at http://www.di.com

Selecting a load cell

As an engineer, you may

need to purchase a load cell to measure a force. Here are a few considerations that will guide

your purchase.

1.

How many force

(and maybe moment) components do you need to measure? Instruments that measure several force

components are more expensive…

2.

Load capacity what is the maximum force you need to measure?

3.

Load range what is the minimum force you need to measure?

4.

Accuracy

5.

Temperature

stability how much will the reading on the cell change

if the temperature changes?

6.

Creep stability if a load is applied to the cell for a long

time, does the reading drift?

7.

Frequency

response how rapidly will the cell respond to time

varying loads? What is the maximum

frequency of loading that can be measured?

8.

Reliability

9.

Cost

2.1.7 Force Laws

In this section, we list

equations that can be used to calculate forces associated with

(i)

Gravity

(ii)

Forces exerted by

linear springs

(iii)

Electrostatic

forces

(iv)

Electromagnetic

forces

(v)

Hydrostatic

forces and buoyancy

(vi)

Aero- and hydro-dynamic

lift and drag forces

Gravitation

Gravity forces acting on

masses that are a large distance apart

Consider

two masses and that are a distance d apart. Newton’s

law of gravitation states that mass will experience a force

where

is a unit vector pointing from mass to mass ,

and G is the Gravitation constant. Mass will experience a force of equal magnitude,

acting in the opposite direction.

In SI units,

The

law is strictly only valid if the masses are very small (infinitely small,

in fact) compared with d so the formula works best for calculating the

force exerted by one planet or another; or the force exerted by the earth on a

satellite.

Gravity forces acting on a small object close to the

earth’s surface

Gravity forces acting on a small object close to the

earth’s surface

For engineering purposes,

we can usually assume that

1.

The earth is spherical,

with a radius R

2.

The object of

interest is small compared with R

3.

The object’s

height h above the earths surface is

small compared to R

If the first two

assumptions are valid, then one can show that Newton’s law of gravitation implies that a mass

m at a height h above the earth’s surface experiences a force

where

M is the mass of the earth; m

is the mass of the object; R is the earth’s radius, G is the

gravitation constant and is a unit vector pointing from the center of

the earth to the mass m. (Why do

we have to show this? Well, the mass m actually experiences a force of

attraction towards every point inside the earth. One might guess that points close to the

earth’s surface under the mass would attract the mass more than those far away,

so the earth would exert a larger gravitational force than a very small object

with the same mass located at the earth’s center. But this turns out not to be the case, as

long as the earth is perfectly uniform and spherical).

If the third assumption (h<<R) is valid, then we can

simplify the force law by setting

where g is a constant, and j is a `vertical’ unit vector (i.e.

perpendicular to the earth’s surface).

In SI units .

The

force of gravity acts at the center of gravity of an object. For most engineering calculations the center

of gravity of an object can be assumed to be the same as its center of

mass. For example, gravity would exert a

force at the center of the sphere that Mickey is holding. The location of the center of mass for

several other common shapes is shown below.

The procedure for calculating center of mass of a complex shaped object

is discussed in more detail in section 6.3.

|

TABLE OF

POSITIONS OF CENTER OF MASS FOR COMMON OBJECTS

|

|

|

|

|

|

Rectangular prism

|

Circular cylinder

|

Half-cylinder

|

|

|

|

|

|

|

|

|

|

Solid hemisphere

|

Thin hemispherical shell

|

Cone

|

|

|

|

|

|

|

|

Triangular Prism

Thin triangular laminate

|

Some subtleties about

gravitational interactions

There

are some situations where the simple equations in the preceding section don’t

work. Surveyors know perfectly well that

the earth is no-where near spherical; its density is also not uniform. The earth’s gravitational field can be quite

severely distorted near large mountains, for example. So using the simple gravitational formulas in

surveying applications (e.g. to find the `vertical’ direction) can lead to

large errors.

Also,

the center of gravity of an object is not

the same as its center of mass. Gravity

is actually a distributed force. When

two nearby objects exert a gravitational force on each other, every point in

one body is attracted towards every point inside its neighbor. The distributed force can be replaced by a

single, statically equivalent force, but the point where the equivalent force

acts depends on the relative positions of the two objects, and is not generally

a fixed point in either solid. One

consequence of this behavior is that gravity can cause rotational

accelerations, as well as linear accelerations.

For example, the resultant force of gravity exerted on the earth by the

sun and moon does not act at the center of mass of the earth. As a result, the earth precesses that is to say, its axis of rotation changes

with time.

Forces exerted by springs

A

solid object (e.g. a rubber band) can be made to exert forces by stretching

it. The forces exerted by a solid that

is subjected to a given deformation depend on the shape of the component, the

materials it is made from, and how it is connected to its surroundings. Solid

objects can also exert moments, or torques we will define these shortly. Forces

exerted by solid components in a machine or structure are complicated, and will

be discussed in detail separately.

Here, we restrict attention to the simplest case: forces exerted by

linear springs.

A spring scale is a good

example of a linear spring. You can

attach it to something at both ends. If you

stretch or compress the spring, it will exert forces on whatever you connected

to.

The forces exerted by the

ends of the spring always act along the line of the spring. The magnitude of the force is (so long as you

don’t stretch the spring too much) given by the formula

where a is the un-stretched spring length; L is the stretched length, and k

is the spring stiffness.

In the SI system, k has units of N/m.

Note that when you draw a

picture showing the forces exerted by a spring, you must always assume that the

spring is stretched, so that the forces exerted by the spring are attractive. If you don’t do this, your sign convention

will be inconsistent with the formula ,

which assumes that a compressed spring (L<a)

exerts a negative force.

Forces exerted by dashpots

A

‘Dashpot’ is somewhat like a spring except that it exerts forces that are

proportional to the relative velocity of its two ends, instead of the relative

displacement. The device is extremely

useful for damping vibrations. The

device usually consists of a plunger that forces air or fluid through a small

orifice the force required to expel the fluid is

roughly proportional to the velocity of the plunger. For an example of a precision dashpot see http://www.airpot.com/beta/html/dashpot_defined.html

The forces exerted by the

ends of the dashpot always act along the line of the dashpot. The magnitude of the force exerted by a fluid

filled dashpot is given by the formula

where L is the length, and is the rate constant of the dashpot. Air filled dashpots are somewhat more

complicated, because the compressibility of the air makes them behave like a

combination of a dashpot and spring connected end-to-end.

In the SI system, has units of Ns/m.

Note that when you draw a

picture showing the forces exerted by a dashpot, you must always assume that

the length of the dashpot is increasing, so that the forces exerted by the ends

of the dashpot are attractive.

Forces exerted by an ‘Inerter’

The ‘Inerter’ is a device that exerts forces

proportional to the relative acceleration

of its two ends. It was invented in

1997 and used in secret by the McLaren Formula 1 racing team to improve the

performance of their cars, but in 2008 was made broadly available (http://www.admin.cam.ac.uk/news/dp/2008081906)

The ‘Inerter’ is a device that exerts forces

proportional to the relative acceleration

of its two ends. It was invented in

1997 and used in secret by the McLaren Formula 1 racing team to improve the

performance of their cars, but in 2008 was made broadly available (http://www.admin.cam.ac.uk/news/dp/2008081906)

The device is so simple

that it is difficult to believe that it has taken over 100 years of vehicle

design to think of it but the secret is really in how to use the

device to design suspensions than in the device itself. The device works by spinning a flywheel

between two moving rods, as sketched in the figure.

The forces exerted by the

ends of the inerter always act along the line of the inerter. The magnitude of the force exerted by an

inerter is given by the formula

where

L is the length, and is the inertia constant of the dashpot.

In the SI system, has units of Ns2/m.

Electrostatic forces

As

an engineer, you will need to be able to design structures and machines that

manage forces. Controlling gravity is,

alas, beyond the capabilities of today’s engineers. It’s also difficult (but

not impossible) to design a spring with a variable stiffness or unstretched

length. But there are forces that you can easily control. Electrostatic and electromagnetic forces are

among the most important ones.

Electrostatic forces are exerted on, and by, charged objects. The concepts of electrical potential, current

and charge are based on experiments. A

detailed discussion of these topics is beyond the scope of this course (it will

be covered in detail in EN51), but electromagnetic and electrostatic forces are

so important in the design of engines and machines that the main rules

governing forces in these systems will be summarized here.

Electrostatic forces acting on two small charged

objects that are a large distance apart

Coulomb’s Law states that if like charges and are induced on two particles that are a

distance d apart, then particle 1

will experience a force

Coulomb’s Law states that if like charges and are induced on two particles that are a

distance d apart, then particle 1

will experience a force

(acting

away from particle 2), where is a fundamental physical constant known as

the Permittivity of the medium

surrounding the particles (like the Gravitational constant, its value must be

determined by experiment).

In

SI units, are specified in Coulombs, d is in meters, and is the permittivity of free space, with fundamental

units . Permittivity is more usually specified using

derived units, in Farads per meter. The Farad is the unit of capacitance.

The

value of for air is very close to that of a

vacuum. The permittivity of a vacuum is

denoted by .

In SI units its value is approximately

Like gravitational forces,

the electrostatic forces acting on 3D objects with a general distribution of

charge must be determined using complicated calculations. It’s worth giving results for two cases that

arise frequently in engineering designs:

Forces acting between charged flat parallel plates

Two parallel plates, which

have equal and opposite charges and are separated by a distance ,

experience an attractive force with magnitude

The force can be thought of

as acting at the center of gravity of the plates.

Two parallel plates, which have area A, are separated by a distance d,

and are connected to a power-supply that imposes an electrical potential

difference V across the plates,

experience an attractive force with magnitude

Two parallel plates, which have area A, are separated by a distance d,

and are connected to a power-supply that imposes an electrical potential

difference V across the plates,

experience an attractive force with magnitude

The force can be thought of

as acting at the center of gravity of the plates.

Applications of electrostatic forces:

Electrostatic

forces are small, and don’t have many applications in conventional mechanical

systems. However, they are often used to

construct tiny motors for micro-electro-mechanical

systems (MEMS). The basic idea is to

construct a parallel-plate capacitor, and then to apply force to the machine by

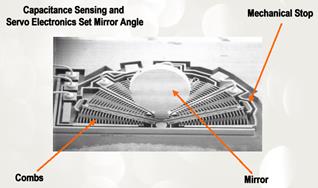

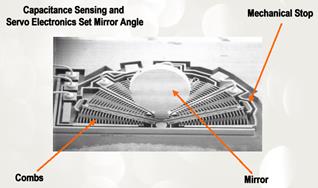

connecting the plates to a power-supply. The pictures below show examples of comb drive motors.

|

|

|

|

An experimental comb drive MEMS actuator developed

at Sandia National Labs, http://mems.sandia.gov/scripts/index.asp

|

A rotary comb drive actuator developed at iolon inc.

Its purpose is to rotate the mirror at the center, which acts as an

optical switch.

|

The

configurations used in practice are basically large numbers of parallel plate

capacitors. A detailed discussion of forces in these systems will be deferred

to future courses.

Electrostatic

forces are also exploited in the design of oscilloscopes, television monitors,

and electron microscopes. These systems

generate charged particles (electrons), for example by heating a tungsten

wire. The electrons are emitted into a

strong electrostatic field, and so are subjected to a large force. The force then causes the particles to

accelerate but we can’t talk about accelerations in this

course so you’ll have to take EN4 to find out what happens next…

Electromagnetic forces

Electromagnetic forces are exploited more widely than

electrostatic forces, in the design of electric motors, generators, and

electromagnets.

Electromagnetic forces are exploited more widely than

electrostatic forces, in the design of electric motors, generators, and

electromagnets.

Ampere’s Law

states that two long parallel wires which have length L, carry electric currents and ,

and are a small distance d apart,

will experience an attractive force with magnitude

where is a constant known as the permeability of free space.

In

SI units, has fundamental units of ,

but is usually specified in derived units of Henry per meter. The Henry is the unit of inductance.

The value of is exactly

H/m

Electromagnetic forces

between more generally shaped current carrying wires and magnets are governed

by a complex set of equations. A full

discussion of these physical laws is beyond the scope of this course, and will

be covered in EN51.

Applications of electromagnetic forces

Electromagnetic forces are

widely exploited in the design of electric motors; force actuators; solenoids;

and electromagnets. All these

applications are based upon the principle that a current-carrying wire in a

magnetic field is subject to a force.

The magnetic field can either be induced by a permanent magnet (as in a

DC motor); or can be induced by passing a current through a second wire (used

in some DC motors, and all AC motors).

The general trends of forces in electric motors follow Ampere’s law: the

force exerted by the motor increases linearly with electric current in the

armature; increases roughly in proportion to the length of wire used to wind

the armature, and depends on the geometry of the motor.

Two examples of DC motors the picture on the right is cut open to show

the windings. You can find more

information on motors at http://my.execpc.com/~rhoadley/magmotor.htm

Hydrostatic and buoyancy forces

When an object is immersed in a stationary fluid, its

surface is subjected to a pressure. The pressure is actually induced in the fluid

by gravity: the pressure at any depth is effectively supporting the weight of

fluid above that depth.

When an object is immersed in a stationary fluid, its

surface is subjected to a pressure. The pressure is actually induced in the fluid

by gravity: the pressure at any depth is effectively supporting the weight of

fluid above that depth.

A pressure is a distributed force. If a pressure p acts on a surface, a small piece of the surface with area is subjected to a force

where

n is a unit vector perpendicular to

the surface. The total force on a surface must be calculated by

integration. We will show how this is

done shortly.

The pressure in a

stationary fluid varies linearly with depth below the fluid surface

where

is atmospheric pressure (often neglected as

it’s generally small compared with the second term); is the fluid density; g is the acceleration due to gravity; and d is depth below the fluid surface.

Archimedes’ principle gives

a simple way to calculate the resultant force exerted by fluid pressure on an

immersed object.

The

magnitude of the resultant force is equal to the weight of water displaced by

the object. The direction is

perpendicular to the fluid surface.

Thus, if the fluid has mass density ,

and a volume of the object lies below the surface of the

fluid, the resultant force due to fluid pressure is

The

force acts at the center of buoyancy

of the immersed object. The center of

buoyancy can be calculated by finding the center of mass of the displaced fluid

(i.e. the center of mass of the portion of the immersed object that lies below

the fluid surface).

The

buoyancy force acts in addition to gravity loading. If the object floats, the gravitational force

is equal and opposite to the buoyancy force.

The force of gravity acts (as usual) at the center of mass of the entire object.

Aerodynamic lift and drag forces

Engineers who design large bridges, buildings, or

fast-moving terrestrial vehicles, spend much time and effort in managing aero-

or hydro-dynamic forces. Hydrodynamic

forces are also of great interest to engineers who design bearings and car

tires, since hydrodynamic forces can cause one surface to float above another,

so reducing friction to very low levels.

Engineers who design large bridges, buildings, or

fast-moving terrestrial vehicles, spend much time and effort in managing aero-

or hydro-dynamic forces. Hydrodynamic

forces are also of great interest to engineers who design bearings and car

tires, since hydrodynamic forces can cause one surface to float above another,

so reducing friction to very low levels.

In general, when air or

fluid flow past an object (or equivalently, if the object moves through

stationary fluid or gas), the object is subjected to two forces:

1.

A Drag force, which acts parallel to the

direction of air or fluid flow

2.

A Lift force, which acts perpendicular to

the direction of air or fluid flow.

The forces act at a point

known as the center of lift of the object but there’s no simple way to predict where

this point is.

The lift force is present

only if airflow past the object is unsymmetrical (i.e. faster above or below

the object). This asymmetry can result

from the shape of the object itself (this effect is exploited in the design of

airplane wings); or because the object is spinning (this effect is exploited by

people who throw, kick, or hit balls for a living).

Two effects contribute to

drag:

(1) Friction between the object’s surface and the fluid or

air. The friction force depends on the

object’s shape and size; on the speed of the flow; and on the viscosity of the fluid, which is a measure

of the shear resistance of the fluid.

Air has a low viscosity; ketchup has a high viscosity. Viscosity is often given the symbol ,

and has the rather strange units in the SI system of .

In `American’ units viscosity has units

of `Poise’ (or sometimes centipoises that’s Poise).

The conversion factor is . (Just

to be confusing, there’s another measure of viscosity, called kinematic viscosity, or specific viscosity, which is ,

where is the mass density of the material. In this course we’ll avoid using kinematic

viscosity, but you should be aware that it exists!) Typical numbers are: Air: for a standard atmosphere (see http://users.wpi.edu/~ierardi/PDF/air_nu_plot.PDF

for a more accurate number) ; Water, ;

SAE40 motor oil ,

ketchup (It’s hard to give a value for the viscosity

of ketchup, because it’s thixotropic.

See if you can find out what this cool word means it’s a handy thing to bring up if you work in

a fast food restaurant.)

(2) Pressure acting on the objects surface. The pressure arises because the air

accelerates as it flows around the object.

The pressure acting on the front of the object is usually bigger than

the pressure behind it, so there’s a resultant drag force. The pressure drag force depends on the

objects shape and size, the speed of the flow, and the fluid’s mass density .

Lift

forces defy a simple explanation, despite the efforts of various authors to

provide one. If you want to watch a

fight, ask two airplane pilots to discuss the origin of lift in your presence. (Of

course, you may not actually know two airplane pilots. If this is the case, and you still want to

watch a fight, you could try http://www.wwe.com/,

or go to a British soccer match). Lift

is caused by a difference in pressure acting at the top and bottom of the object,

but there’s no simple way to explain the origin of this pressure difference. A correct explanation of the origin of lift

forces can be found at http://www.grc.nasa.gov/WWW/K-12/airplane/right2.html

(this site has some neat Java applets that calculate pressure and flow past

airfoils). Unfortunately there are

thousands more books and websites with incorrect explanations of lift, but you

can find those for yourself (check out the explanation from the FAA!)

Lift

and drag forces are usually quantified by defining a coefficient of lift and a coefficient

of drag for the object, and then using the formulas

Here,

is the air or fluid density, V

is the speed of the fluid, and and are measures of the area of the object. Various measures of area are used in practice

when you look up values for drag coefficients

you have to check what’s been used. The object’s

total surface area could be used. Vehicle manufacturers usually use the projected frontal area (equal to car height

x car width for practical purposes) when reporting drag coefficient. and are dimensionless, so they have no units.

The drag and lift

coefficients are not constant, but depend on a number of factors, including:

1. The shape of the object

2. The object’s orientation relative to the flow

(aerodynamicists refer to this as the `angle of attack’)

3. The fluid’s viscosity ,

mass density ,

flow speed V and the object’s size.

Size can be quantified by or ;

other numbers are often used too. For

example, to quantify the drag force acting on a sphere we use its diameter D.

Dimensional analysis shows that and can only depend on these factors through a

dimensionless constant known as `Reynold’s number’, defined as

|

|

|

The

variation of drag coefficient with Reynolds number Re for a smooth sphere.

|

For example, the graph on the right shows the variation

of drag coefficient with Reynolds number for a smooth sphere, with diameter D.

The projected area was used to define the drag coefficient

Many

engineering structures and vehicles operate with Reynolds numbers in the range ,

where drag coefficients are fairly constant (of order 0.01 - 0.5 or so). Lift coefficients for most airfoils are of

order 1 or 2, but can be raised as high as 10 by special techniques such as

blowing air over the wing)

Lift

and drag coefficients can be calculated approximately (you can buy software to

do this for you, e.g. at http://www.hanleyinnovations.com/walite.html

. Another useful resource is www.desktopaero.com/appliedaero ). They usually have to be measured to get really

accurate numbers.

Tables of approximate

values for lift and drag coefficients can be found at http://aerodyn.org/Resources/database.html

Lift and drag forces are of

great interest to aircraft designers.

Lift and drag forces on an airfoil are computed using the usual formula

The

wing area where c

is the chord of the wing (see the picture) and L is its length, is used in defining both the lift and drag

coefficient.

The

variation of and with angle

of attack are crucial in the design of aircraft. For reasonable values of (below stall - say less than 10 degrees) the

behavior can be approximated by

where

,

and are more or less constant for any given

airfoil shape, for practical ranges of Reynolds number. The first term in the drag coefficient, ,

represents parasite drag due to viscous drag and some pressure

drag. The second term is called induced

drag, and is an undesirable by-product of lift.

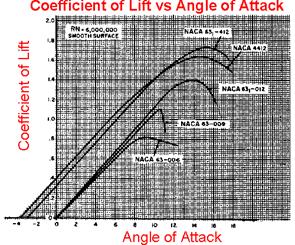

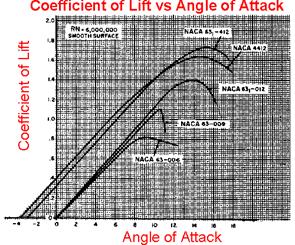

The

graphs on the right, (taken from `Aerodynamics for Naval Aviators, H.H. Hurt,

U.S. Naval Air Systems Command reprint’) shows some experimental data for lift

coefficient as a function of AOA (that’s angle of attack,

but you’re engineers now so you have to talk in code to maximize your nerd

factor. That’s NF). The data suggest that ,

and in fact a simple model known as `thin airfoil theory’ predicts that lift

coefficient should vary by per radian (that works out as 0.1096/degree)

The induced drag

coefficient can be estimated from the formula

where

, L is the length of the wing and c is its width; while e is a constant known as the `Oswald efficiency

factor.’ The constant e is always less than 1 and is of order

0.9 for a high performance wing (eg a jet aircraft or glider) and of order 0.7

for el cheapo wings.

The parasite drag

coefficient is of order 0.05 for the wing of a small

general aviation aircraft, and of order 0.005 or lower for a commercial

airliner.

Interatomic forces

Engineers

working in the fields of nanotechnology, materials design, and bio/chemical

engineering are often interested in calculating the motion of molecules or

atoms in a system.

They

do this using `Molecular Dynamics,’ which is a computer method for integrating

the equations of motion for every atom in the solid. The equations of motion are just Newton’s law F=ma for each atom but for the method to work, it is necessary to

calculate the forces acting on the atoms.

Specifying these forces is usually the most difficult part of the

calculation.

The forces are computed

using empirical force laws, which are either determined experimentally, or

(more often) by means of quantum-mechanical calculations. In the simplest models, the atoms are assumed

to interact through pair forces. In this

case

·

The forces

exerted by two interacting atoms depends only on their relative positions, and

is independent on the position of other atoms in the solid

·

The forces act

along the line connecting the atoms.

·

The magnitude of

the force is a function of the distance between them. The function is chosen so that (i) the force

is repulsive when the atoms are close together; (ii) the force is zero at the

equilibrium interatomic spacing; (iii) there is some critical distance where

the attractive force has its maximum value (see the figure) and (iv) the force

drops to zero when the atoms are far apart.

Various

functions are used to specify the detailed shape of the force-separation

law. A common one is the so-called

‘Lennard Jones’ function, which gives the force acting on atom (1) as

Here a is the equilibrium separation between the atoms, and E is the total bond energy the amount of work required to separate the

bond by stretching it from initial length a

to infinity.

This

function was originally intended to model the atoms in a Noble gas like He or Ar, etc. It is sometimes used in simple models of

liquids and glasses. It would not be a

good model of a metal, or covalently bonded solids. In fact, for these materials pair potentials

don’t work well, because the force exerted between two atoms depends not just

on the relative positions of the two atoms themselves, but also on the

positions of other nearby atoms. More

complicated functions exist that can account for this kind of behavior, but

there is still a great deal of uncertainty in the choice of function for a particular

material.

2.2 Moments

The

moment of a force is a measure of its tendency to rotate an object about

some point. The physical significance of

a moment will be discussed later. We

begin by stating the mathematical definition of the moment of a force about a

point.

2.2.1

Definition of the moment of a force.

To calculate the moment of a force about some point,

we need to know three things:

To calculate the moment of a force about some point,

we need to know three things:

1. The force vector, expressed as components in a basis ,

or better as

2. The position vector (relative to some convenient

origin) of the point where the force is acting or better

3. The position vector of the point (say point A)

we wish to take moments about (you must use the same origin as for 2) or

The moment of F

about point A is then defined as

We

can write out the formula for the components of in longhand by using the definition of a cross

product

The moment of F about

the origin is a bit simpler

or, in terms of components

2.2.2 Resultant moment exerted by a force system.

Suppose

that N forces act at positions . The resultant

moment of the force system is simply

the sum of the moments exerted by the forces.

You can calculate the resultant moment by first calculating the moment

of each force, and then adding all the moments together (using vector sums).

Just one word of caution is

in order here when you

compute the resultant moment, you must take moments about the same point for

every force.

Taking moments about a

different point for each force and adding the result is meaningless!

2.2.3

Examples of moment calculations using the vector formulas

We work through a few

examples of moment calculations

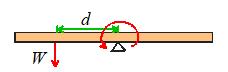

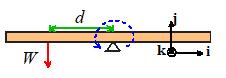

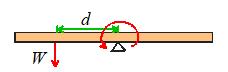

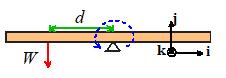

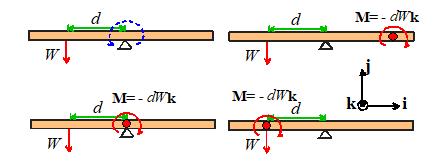

Example 1: The beam shown

below is uniform and has weight W.

Calculate the moment exerted by the gravitational force about points A and B.

We

know (from the table provided earlier) that the center of gravity is half-way

along the beam.

The force (as a vector) is

To

calculate the moment about A, we take the origin at A. The position vector of

the force relative to A is

The moment about A

therefore

To calculate the moment

about B, we take B as the origin. The

position vector of the force relative to B is

Therefore

Example 2. Member

AB of a roof-truss is subjected

to a vertical gravitational force W

and a horizontal wind load P. Calculate the moment of the resultant force

about B.

Example 2. Member

AB of a roof-truss is subjected

to a vertical gravitational force W

and a horizontal wind load P. Calculate the moment of the resultant force

about B.

Both the wind load and

weight act at the center of gravity.

Geometry shows that the position vector of the CG with respect to B is

The resultant force is

Therefore the moment about

B is

Example 3. The structure

shown is subjected to a force T

acting at E along the line EF.

Calculate the moment of T

about points A and D.

Example 3. The structure

shown is subjected to a force T

acting at E along the line EF.

Calculate the moment of T

about points A and D.

This example requires a lot more work. First we need to write down the force as a

vector. We know the magnitude of the

force is T, so we only need to work

out its direction. Since the force acts

along EF, the direction must be a unit vector pointing along EF.

It’s not hard to see that the vector EF

is

We can divide by the length

of EF ( ) to find a unit vector pointing in the

correct direction

The force vector is

Next, we need to write down

the necessary position vectors

Force:

Point

A:

Point

D:

Finally, we can work

through the necessary cross products

Clearly,

vector notation is very helpful when solving 3D problems!

Example 4. Finally, we work through a

simple problem involving distributed

loading. Calculate expressions for the

moments exerted by the pressure acting on the beam about points A and B.

Example 4. Finally, we work through a

simple problem involving distributed

loading. Calculate expressions for the

moments exerted by the pressure acting on the beam about points A and B.

An

arbitrary strip of the beam with length dx

is subjected to a force

The

position vector of the strip relative to A is

The

force acting on the strip therefore exerts a moment

The

total moment follows by summing (integrating) the forces over the entire length

of the beam

The

position vector of the strip relative to B is

The

force acting on the strip exerts a moment

The

total moment follows by summing (integrating) the forces over the entire length

of the beam

2.2.4

The Physical Significance of a Moment

A force acting on a solid

object has two effects: (i) it tends to accelerate the object (making the

object’s center of mass move); and (ii) it tends to cause the object to rotate.

1.

The moment of

a force about some point quantifies its tendency to rotate an object about that

point.

2.

The

magnitude of the moment specifies the magnitude of the rotational force.

3.

The direction

of a moment specifies the axis of rotation associated with the rotational

force, following the right hand screw convention.

Let’s explore these

statements in more detail.

The

best way to understand the physical significance of a moment is to think about

the simple experiments you did with levers & weights back in

kindergarten. Consider a beam that’s

pivoted about some point (e.g. a see-saw).

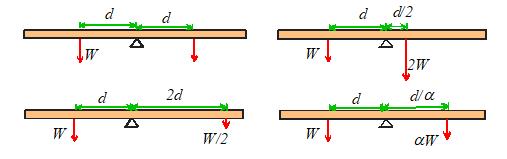

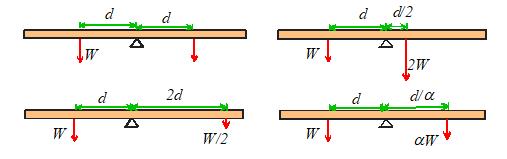

Hang a weight W at

some distance d to the left of the pivot, and the beam will rotate

(counter-clockwise)

To stop the beam rotating,

we need to hang a weight on the right side of the pivot. We could

(a)

Hang a weight W

a distance d to the right of the pivot

(b)

Hang a weight 2W

a distance d/2 to the right of the pivot

(c)

Hang a weight W/2

a distance 2d to the right of the pivot

(d)

Hang a weight a distance to the right of the pivot.

Four ways to balance the beam

These

simple experiments suggest that the turning tendency of a force about some

point is equal to the distance from the point multiplied by the force. This is certainly consistent with

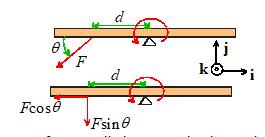

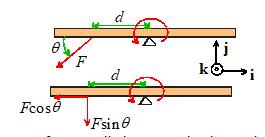

To see where the cross product in the definition comes

from, we need to do a rather more sophisticated experiment. Let’s now apply a force F at a

distance d from the pivot, but now instead of making the force act

perpendicular to the pivot, let’s make it act at some angle. Does this have a

turning tendency Fd?

To see where the cross product in the definition comes

from, we need to do a rather more sophisticated experiment. Let’s now apply a force F at a

distance d from the pivot, but now instead of making the force act

perpendicular to the pivot, let’s make it act at some angle. Does this have a

turning tendency Fd?

A

little reflection shows that this cannot be the case. The force F can be split into two

components perpendicular to the beam, and parallel to it. But the component parallel to the beam will

not tend to turn the beam. The turning

tendency is only .

Let’s compare this with . Take the origin at the pivot, then

so the magnitude of the

moment correctly gives the magnitude of the turning tendency of the force. That’s why the definition of a moment needs a

cross product.

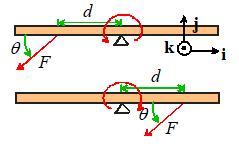

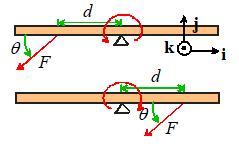

Finally we need to think

about the significance of the direction of the moment. We can get some insight by calculating for forces acting on our beam to the right and

left of the pivot

For the

force acting on the left of the pivot, we just found

For the force acting on the

right of the pivot

Thus, the force on the left

exerts a moment along the +k direction, while the force on the right

exerts a moment in the k

direction.

Notice

also that the force on the left causes counterclockwise rotation; the force on

the right causes clockwise rotation.

Clearly, the direction of the moment has something to do with the

direction of the turning tendency.

Specifically,

the direction of a moment specifies the axis associated with the rotational

force, following the right hand screw convention.

It’s

best to use the screw rule to visualize the effect of a moment hold your right hand as shown, with the thumb

pointing along the direction of the moment.

Your curling fingers (moving from your palm to the finger tips) then

indicate the rotational tendency associated with the moment. Try this for the beam problem. With your thumb pointing along +k (out

of the picture), your fingers curl counterclockwise. With your thumb pointing along k, your

fingers curl clockwise.

2.2.5 A few tips on

calculating moments

The safest way to calculate the moment of a force is

to slog through the formula, as described at the start of this

section. As long as you can write down

position vectors and force vectors correctly, and can do a cross product, it is

totally fool-proof.

The safest way to calculate the moment of a force is

to slog through the formula, as described at the start of this

section. As long as you can write down

position vectors and force vectors correctly, and can do a cross product, it is

totally fool-proof.

But if you have a good

physical feel for forces and their effects you might like to make use of the

following short cuts.

1. The direction of a

moment is always perpendicular to both and F. For 2D problems, and F lie in the same plane,

so the direction of the moment must be perpendicular to this plane.

Thus, a set of 2D forces in

the {i,j} plane can only exert moments in the direction this makes calculating moments in 2D problems

rather simple; we just have to figure out whether the sign of a moment is

positive or negative.

You can do a quick

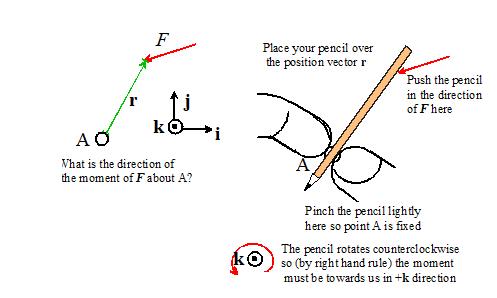

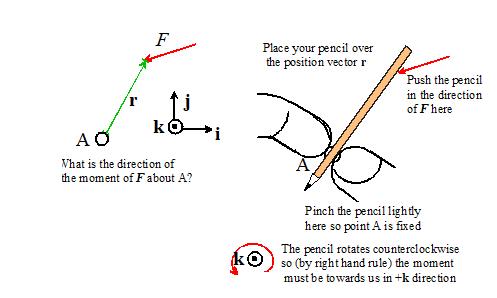

experiment to see whether the direction is +k or k. Suppose you want to find the direction of

the moment caused by F in the picture above about the point A. To do so,

(i)

Place your pencil

on the page so that it lies on the line connecting A to the force.

(ii)

Pinch the pencil

lightly at A so it can rotate about A, but A remains fixed.

(iii)

Push on the

pencil in the direction of the force at B.

If the pencil rotates counterclockwise, the direction of the moment of F

about A is out of the picture (usually +k). If it rotates clockwise, the direction of the

moment is into the picture (k). If it doesn’t rotate, you’re either

holding the pencil in a death grip at A (then the experiment won’t work) or

else the force must be acting along the pencil

in this case the moment is zero.

In

practice you will soon find that you can very quickly tell the direction of a

moment (in 2D, anyway) just by looking at the picture, but the experiment might

help until you develop this intuition.

2.

The magnitude of a moment about some point is equal to the perpendicular

distance from that point to the line of action of the force, multiplied by the

magnitude of the force.

Again,

this trick is most helpful in 2D. Its

use is best illustrated by example.

Let’s work through the simple 2D example problems again, but now use the

short-cut.

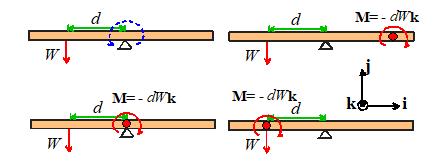

Example 1: The beam shown below is uniform and has

weight W. Calculate the moment exerted

by the gravitational force about points A and B.

Example 1: The beam shown below is uniform and has

weight W. Calculate the moment exerted

by the gravitational force about points A and B.

The perpendicular distance

from a vertical line through the CG to A is L/2. The pencil trick shows that W exerts a clockwise moment about

A. Therefore

Similarly, the perpendicular

distance to B is L/2, and W exerts a counterclockwise moment about

B. Therefore

Example 2.

Member AB

of a roof-truss is subjected to a vertical gravitational force W and a horizontal wind load P.

Calculate the moment of the resultant force about B.

Example 2.

Member AB

of a roof-truss is subjected to a vertical gravitational force W and a horizontal wind load P.

Calculate the moment of the resultant force about B.

The perpendicular distance

from the line of action of W to B is L/2.

W exerts a counterclockwise

moment about B. Therefore W exerts a moment

The perpendicular distance

from the line of action of P to B is . P

also exerts a counterclockwise moment about B.

Therefore

The total moment is

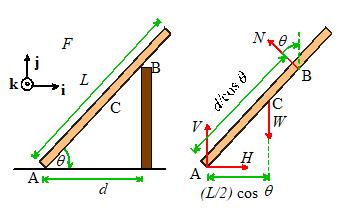

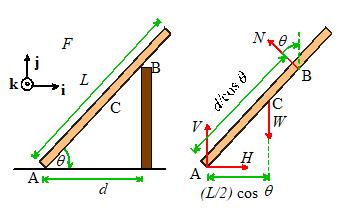

Example

3: It is traditional in

elementary statics courses to solve lots of problems involving ladders (oh boy!

Aren’t you glad you signed up for engineering?) . The picture below shows a ladder of length L

and weight W resting on the top of a frictionless wall. Forces acting on

the ladder are shown as well. Calculate the moments about point A of the

reaction force at B (which acts perpendicular to the ladder) and the weight

force at C (which acts at the center of gravity, half-way up the ladder).

Example

3: It is traditional in

elementary statics courses to solve lots of problems involving ladders (oh boy!

Aren’t you glad you signed up for engineering?) . The picture below shows a ladder of length L

and weight W resting on the top of a frictionless wall. Forces acting on

the ladder are shown as well. Calculate the moments about point A of the

reaction force at B (which acts perpendicular to the ladder) and the weight

force at C (which acts at the center of gravity, half-way up the ladder).

The perpendicular distance

from point A to the line along which N acts is . The pencil experiment (or inspection) shows

that the direction of the moment of N about A is in the +k

direction. Therefore the trick

(perpendicular distance times force) gives

The perpendicular distance

from point A to the line along which W is acting is . The direction of the moment is k. Therefore

Let’s compare these with

the answer we get using . We can take the origin to be at A to make things simple. Then, for the force at B

giving the same answer as

before, but with a whole lot more effort!

Similarly, for the weight

force

3.

The moment exerted by a force is unchanged if the force is moved in a

direction parallel to the direction of the force.

This

is rather obvious in light of trick (2), but it’s worth stating anyway.

4.

The component of moment exerted by a force about an axis through a point can

be calculated by (i) finding the two force components perpendicular to the

axis; then (ii) multiplying each force component by its perpendicular distance

from the axis; and (iii) adding the contributions of each force component

following the right-hand screw convention.

The wording of this one

probably loses you, so let’s start by trying to explain what this means.

First, let’s review what we

mean by the component of a moment about some axis. The formula for the moment of a force about

the origin is

This has three components -

about the i axis, about the j axis, and about the k axis.

The

trick gives you a quick way to calculate one of the components. For example, let’s try to find the i

component of the moment about the origin exerted by the force shown in the

picture.

The rule says

(i)

Identify the

force components perpendicular to the i axis that’s and in this case;

(ii)

Multiply each

force component by its perpendicular distance from the axis. Drawing a view down the i axis is

helpful. From the picture, we can see

that is a distance y from the axis, and is a distance z from the axis. The two contributions we need are thus and .

(iii)

Add the two contributions according to the right hand

screw rule. We know that each force

component exerts a moment - we have to figure out which one is +i and

which is i. We can do the pencil experiment to figure

this out the answer is that exerts a moment along +i, while causes a moment along i. So finally .

Add the two contributions according to the right hand

screw rule. We know that each force

component exerts a moment - we have to figure out which one is +i and

which is i. We can do the pencil experiment to figure

this out the answer is that exerts a moment along +i, while causes a moment along i. So finally .

Example: The structure shown is subjected to a vertical force V and horizontal force H acting at E. Calculate the k component of moment exerted about

point A by the resultant force.

Our

trick gives the answer immediately.

First, draw a picture looking down the k axis

Clearly, the force H

exerts a k component of moment ,

while the force V exerts a k component of moment . The total k component of moment is

This trick clearly can save a great deal of time. But to make use of it, you need excellent 3D

visualization skills.

2.3 Force Couples, Pure Moments, Couples and Torques

We

have seen that a force acting on a rigid body has two effects: (i) it tends to

move the body; and (ii) it tends to rotate the body.

A natural question arises is there a way to rotate a body without moving

it? And is there a kind of force that

causes only rotation without translation?

The answer to both questions

is yes.

2.3.1 Force

couples

A system of forces that exerts a resultant moment, but

no resultant force, is called a force couple.

A system of forces that exerts a resultant moment, but

no resultant force, is called a force couple.

The

simplest example of a force couple consists of two equal and opposite forces and acting some distance apart. Suppose that the force acts at position while the force acts at position The resultant moment is

Of course, the vector is just the vector from the point where acts to the point where acts.

This gives a quick way to calculate the moment induced by a force

couple:

The

moment induced by two equal and opposite forces is equal to the moment of one

force about the point of action of the other. It doesn’t matter which force

you use to do this calculation.

Note that a force couple

(i)

Has zero

resultant force

(ii)

Exerts the same

resultant moment about all points.

Its effect is to induce

rotation without translation.

The

effect of a force couple can therefore be characterized by a single vector

moment M. The physical

significance of M is equivalent to the physical significance of the

moment of a force about some point. The

direction of M specifies the axis associated with the rotational

force. The magnitude of M

specifies the intensity of the rotational force.

There are many practical examples of force

systems that are best thought of as force-couple systems. They include

- The forces exerted by your hand on a screw-driver

- The forces exerted by the tip of a screw-driver

on the head of a screw

- The forces exerted by one part of a constant

velocity joint on another

- Drag forces acting on a spinning propeller

2.3.2 Pure moments,

couples and torques.- Definition,

Physical Interpretation, and Examples

A pure

moment is a rotational force. Its

effect is to induce rotation, without translation just like a force couple.

Couples and torques are other

names for a pure moment.

A

pure moment is a vector quantity it has magnitude and direction. The physical significance of the magnitude

and direction of a pure moment are completely equivalent to the moment

associated with a force couple system. The direction of a moment indicates the

axis associated with its rotational force (following the right hand screw

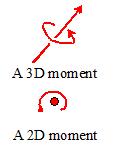

convention); the magnitude represents the intensity of the force. A moment is often denoted by the symbols

shown in the figure.

The concept of a pure moment takes some getting used

to. Its physical effect can be

visualized by thinking about our beam-balancing problem again.

The concept of a pure moment takes some getting used

to. Its physical effect can be

visualized by thinking about our beam-balancing problem again.

The picture above shows the

un-balanced beam. We saw earlier that we

can balance the beam again by adding a second force, which induces a moment

equal and opposite to that of the force W.

We can also balance the beam

by applying a pure moment to it.

Since the moment of W is ,

a moment applied anywhere on the beam would balance it.

You

could even apply the moment to the left of the beam even right on top of the force W if you

like!

2.3.3 Units and typical

magnitudes of moments

In the SI system, moments

have units of Nm (Newton-meters).

In the US system,

moments have units of ft-lb (foot pounds)

The conversion factor is 1 Nm

= 0.738 ft lb; or 1 ft-lb = 1.356 Nm.

Typical magnitudes are:

- Max torque exerted by a small Lego motor: 0.1 Nm

- Typical torque output of a typical car engine

300-600 Nm

- Breaking torque of a human femur: 140Nm

2.3.4

Measuring Moments

Just as you can buy a force transducer to measure

forces, you can buy a force transducer that measures moments. We showed an example of a force-transducer

attached to the wheel of a car during our earlier discussion of force

transducers.

Another common moment-measuring system is a torque-wrench. (So then is Oprah a talk wench?) When you

tighten the bolts on a precision machine, it’s important to torque them

correctly. If you apply too much torque,

you will strip the thread. If you don’t

apply enough, the bolt will work itself loose during service.

You can buy a tool that measures the moment that you

apply to a bolt while tightening it. The

device may be mechanical, or electronic.

An example (see www.mac.ie/whatwedo/ torquestory.asp ) is shown below.

2.3.5 Engineering systems that exert

torques

There

are many practical examples of moments, or torques, in engineering systems. For

example,

(i)

The driving axle

on your car turns the wheels by exerting a moment on them.

(i)

The drive shaft

of any motor exerts a torque on whatever it’s connected to. In fact, motors are usually rated by their

torque capacity.

(ii)

The purpose of a

gearbox is to amplify or attenuate torque.

You apply a torque to the input shaft, and get a bigger or smaller

torque from the output shaft. To do

this, the input and output shafts have to rotate at different speeds. There are also some clever gearboxes that

allow you to add torques together they are used in split-power variable speed

transmissions, for example.

(iii)

A torque converter serves a similar

purpose to a gearbox. Unlike a gearbox,

however, the input and output shafts don’t rotate at the same speed. The output shaft can be stationary, exerting a

large torque, while the input shaft rotates quickly under a modest torque. It is used as part of an automatic

transmission system in a car.

(iv)

Moments also

appear as reaction forces. For

example, the resistance you feel to turning the steering wheel of your car is

caused by moments acting on the wheels where they touch the ground. The rolling resistance you feel when you ride

your bike over soft ground or grass is also due to a moment acting where the

wheel touches the ground.

(v)

Moments appear as

internal forces in structural members or components. For example, a beam will bend because of an

internal moment whose direction is transverse to the direction of the

beam. A shaft will twist because of an

internal moment whose direction is parallel to the shaft. Just as an internal force causes points in a

solid to move relative to each other, an internal moment causes points to rotate

relative to each other.

2.4 Constraint and reaction forces and moments

Machines

and structures are made up of large numbers of separate components. For example, a building consists of a steel

frame that is responsible for carrying most of the weight of the building and

its contents. The frame is made up of

many separate beams and girders, connected to one another in some way. Similarly, an automobile’s engine and

transmission system contain hundreds of parts, all designed to transmit forces

exerted on the engine’s cylinder heads to the ground.

To

analyze systems like this, we need to know how to think about the forces exerted

by one part of a machine or structure on another.

We

do this by developing a set of rules that specify the forces associated

with various types of joints and connections.

Forces

associated with joints and connections are unlike the forces described in the

preceding section. For all our preceding

examples, (e.g. gravity, lift and drag forces, and so on) we always knew everything

about the forces magnitude, direction, and where the force

acts.

In

contrast, the rules for forces and moments acting at joints and contacts don’t

specify the forces completely. Usually

(but not always), they will specify where the forces act; and they will

specify that the forces and moments can only act along certain directions. The magnitude of the force is always

unknown.

2.4.1 Constraint forces:

overview of general nature of constraint forces

The general nature of a contact force is nicely

illustrated by a familiar example a person, standing on a floor (a Sumo wrestler

was selected as a model, since they are particularly interested in making sure

they remain in contact with a floor!).

You know the floor exerts a force on you (and you must exert an equal

force on the floor). If the floor is

slippery, you know that the force on you acts perpendicular to the floor, but

you can’t make any measurements on the properties of the floor or your feet to

determine what the force will be.

The general nature of a contact force is nicely

illustrated by a familiar example a person, standing on a floor (a Sumo wrestler

was selected as a model, since they are particularly interested in making sure

they remain in contact with a floor!).

You know the floor exerts a force on you (and you must exert an equal

force on the floor). If the floor is

slippery, you know that the force on you acts perpendicular to the floor, but

you can’t make any measurements on the properties of the floor or your feet to

determine what the force will be.

In

fact, the floor will always exert on your feet whatever force is necessary

to stop them sinking through the floor.

(This is generally considered to be a good thing, although there are

occasions when it would be helpful to be able to break this law).

We

can of course deduce the magnitude of the force, by noting that since you don’t

sink through the floor, you are in equilibrium (according to Newton’s definition anyway you may be far from equilibrium

mentally). Let’s say you weight 300lb

(if you don’t, a visit to Dunkin Donuts will help you reach this weight). Since the only forces acting on you are

gravity and the contact force, the resultant of the contact force must be equal

and opposite to the force of gravity to ensure that the forces on you sum to

zero. The magnitude of the total contact force is therefore 300lb. In addition,

the resultant of the contact force must act along a line passing through your

center of gravity, to ensure that the moments on you sum to zero.

From

this specific example, we can draw the following general rules regarding

contact and joint forces

(1) All contacts and joints impose constraints on

the relative motion of the touching or connected components that is to say, they allow only certain types

of relative motion at the joint. (e.g. the floor imposes the constraint that

your feet don’t sink into it)

(2) Equal and opposite forces and moments act on the two

connected or contacting objects. This

means that for all intents and purposes, a

constraint force acts in more than one direction at the same time. This is perhaps the most confusing feature of

constraint forces.

(3) The direction of the forces and moments acting on the

connected objects must be consistent with the allowable relative motion at the

joint (detailed explanation below)

(4) The magnitude of the forces acting at a joint or

contact is always unknown. It can sometimes

be calculated by considering equilibrium (or for dynamic problems, the

motion) of the two contacting parts (detailed explanation later).

Because forces acting at

joints impose constraints on motion, they are often called constraint

forces.

They are also called reaction

forces, because the joints react to impose restrictions on the

relative motion of the two contacting parts.

2.4.2 How to determine

directions of reaction forces and moments at a joint

Let’s

explore the meaning of statement (3) above in more detail, with some specific

examples.

In

our discussion of your interaction with a slippery floor, we stated that the

force exerted on you by the floor had to be perpendicular to the floor. How do we know this?

Because,

according to (3) above, forces at the contact have to be consistent with the

nature of relative motion at the contact or joint. If you stand on a slippery floor, we know

(1) You can slide freely in any direction parallel to the

floor. That means there can’t be a force

acting parallel to the floor.

(2) If someone were to grab hold of your head and try to

spin you around, you’d rotate freely; if someone were to try to tip you over,

you’d topple. Consequently, there can’t be any moment acting on you.

(3) You are prevented from sinking vertically into the

floor. A force must act to prevent this.

(4) You can remove your feet from the floor without any

resistance. Consequently, the floor can

only exert a repulsive force on you, it can’t attract you.

You

can use similar arguments to deduce the forces associated with any kind of

joint. Each time you meet a new kind of

joint, you should ask

(1) Does the connection allow the two connected solids

move relative to each other? If so, what

is the direction of motion? There can be no component of reaction force along

the direction of relative motion.

(2) Does the connection allow the two connected solids

rotate relative to each other? If so,