PROVIDENCE, R.I. [Brown University] — For the past seven years, a rotating group of Brown University undergraduates has been toiling away quietly in the Barus and Holley building — designing, building and testing a small satellite with the hope of ultimately sending into orbit.

Last week that satellite, a 4-inch cube dubbed EQUiSat, passed its final preflight checks and is “go” for a scheduled May 20 launch.

“When we completed all the systems checks and everything worked perfectly, I think we were honestly in disbelief,” said Hunter M. Ray, a senior engineering concentrator and the team’s project manager. “Despite having gained significantly more confidence in the satellite over the past few months, so much has gone wrong during the course of the program. It’s a relief for it to have all gone well.”

For Hannah Varner, who graduated in 2014 as a team leader when the group first applied for a launch under NASA’s CubeSat Launch Initiative, the feeling was something more like elation.

“The shortest version of how I feel is: AHHHHHHHH!!!!!!!!!!!!!!!!,” she wrote in an email. “Sure we dreamt about the mythical time of ‘launch,’ but it was miles from reality when we wrote the application to NASA in 2014. [But now] it’s finally real.”

Very real.

EQUiSat is now cleared to be included on a NASA resupply mission to the International Space Station (ISS), scheduled to launch aboard an Antares rocket on May 1 from Wallops Island, Virginia. Sometime in late May or early June, ISS astronauts will deploy EQUiSat, along with several other CubeSats, into orbit some 250 miles above the Earth.

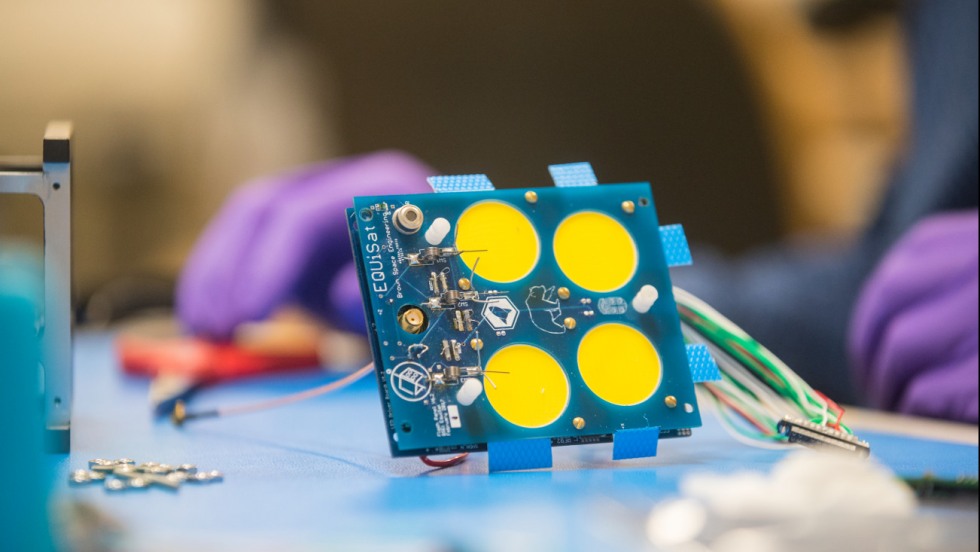

The satellite’s mission is an educational one. The aim is for the satellite to be an orbiting ambassador to space, showing people that the final frontier is within their grasp. Four high-powered LEDs will flash brightly enough to be seen from Earth as the EQUiSat passes across the night sky. The satellite will broadcast a signal over amateur radio with its position in orbit and data from its sensors. Brown undergraduates will develop K-12 curricula around the satellite, arrange watch parties and other events during the satellite’s mission. EQUiSat should be in orbit anywhere from one to two years before its orbit decays and it burns up in the atmosphere.

The Brown community will have a chance to see EQUiSat, and bid it farewell before its journey to space on Friday, March 16, when it will be on display in the Hazeltine Commons in the Engineering Research Center.

A long road

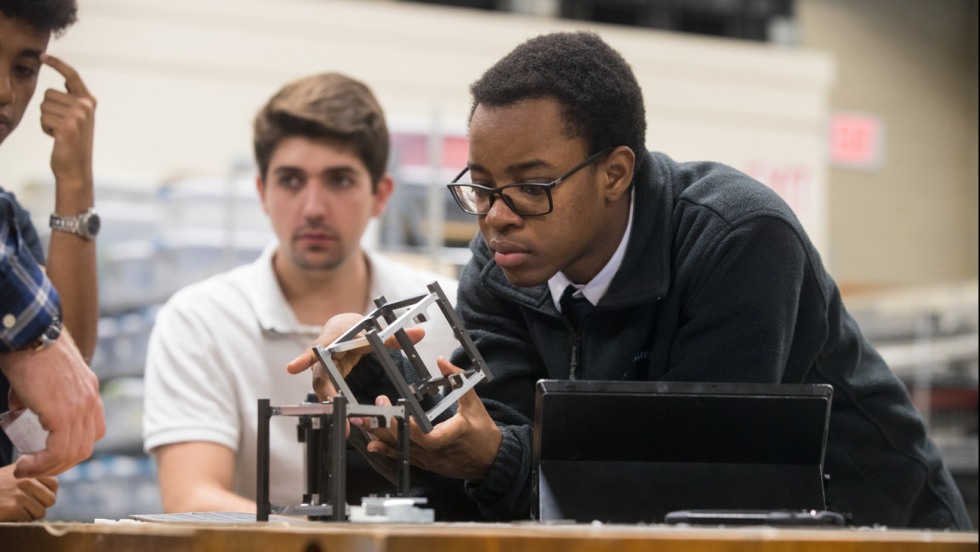

The satellite team, now dubbed Brown Space Engineering (BSE), started in 2012. Max Monn, then an undergraduate and now a Ph.D. student at Brown, first got the idea along with a few classmates to try to build and launch a satellite. The group, then just a handful of students (its ranks have since swelled to more than 80 students), started working up some designs, and eventually the group applied to NASA for space on a rocket.

They were a bit stunned when they were selected for a launch. Ever since, the group has been wrestling with the myriad challenges involved in building a satellite from scratch.

It’s possible to piece together a CubeSat using commercially available satellite parts. But that would cost tens of thousands of dollars. As part of their mission to demonstrate the accessibility of space, the Brown team wanted to build a satellite that could be reproduced for less than $5,000. That meant building many of the spacecraft’s parts and critical systems themselves.

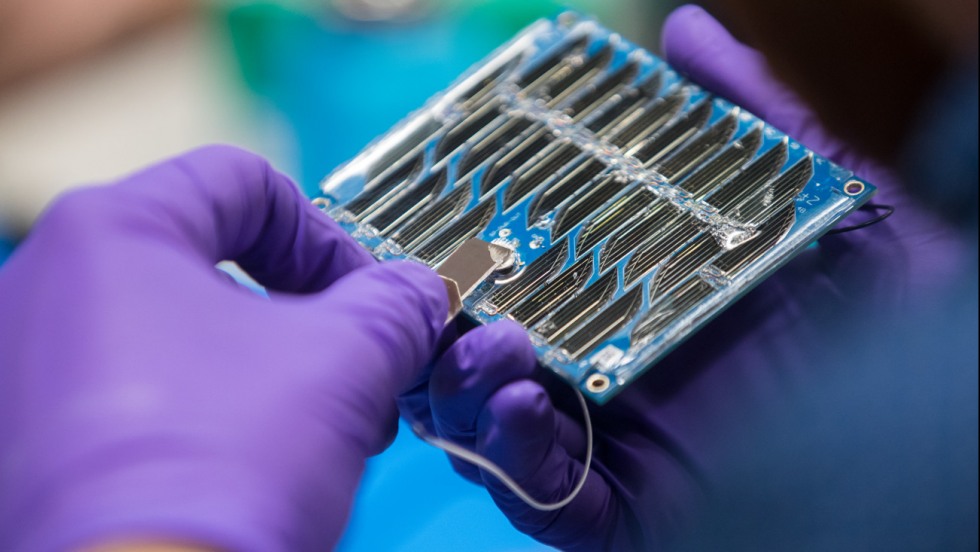

They milled the satellite’s chassis from a single block of aluminum. They built their own solar panels, developed their own electronics and wrote the computer code that makes it all work.

The solar panels were a major challenge, says Anand Lalwani, a BSE member who currently leads the satellite’s power team. They’re made from scrap gallium arsenide solar cells. The manufacturer trims large solar cells to size, and these cutoffs are sold to the team for only $4 a cell.

“The problem is these are very, very delicate,” Lalwani said. “If you just touch one with your fingernail, it breaks.”

That’s not great for something that needs to survive a rocket ride into space. So the team had to make a coating that would protect the cells that was durable, lightweight and didn’t block light from getting to the cells. It took a year, Lalwani said, to find the right mix of chemicals for a coating that could be applied uniformly, with no bubbles. In the vacuum of space, any bubbles would quickly expand and the coating would fail.

Lalwani said finally perfecting the right procedure for making the coating was a rewarding experience he and the rest of the team will carry with them after Brown.

“Every Sunday we’d come and try a new batch of coating and it would fail miserably,” he said. “But to be able to keep coming back and trying something new until we got it, that’s something that’s characteristic of the real world — BSE has prepared us to be able to do that.”

The software side of the project posed unique challenges as well, said Tyler Fox, who led the software team. Fox worked with the team as an undergrad, and this year as a master’s student in computer science. The code he and his team developed will deploy the satellite’s antenna, enable the satellite to communicate with ground stations and tell the LEDs when to flash.

The main challenge, Fox says, was coming up with code that would be flawless in its initial iteration.

“We’re so used to [software] updates,” Fox said. “Our apps update constantly. You can download an update for your toaster nowadays. If there’s a bug, you just update and fix it. But for this, version 1.0 has to be perfect or it’s a big problem. There’s no practice run in space.”

In the end, the team succeeded in designing a spacecraft that could be replicated for under $5,000.

“The materials cost for EQUiSat is $3776.61, to be exact,” Ray said.

Final exams

The team’s work hit a fever pitch as deadlines for NASA’s final flight-readiness testing drew near.

“The past few months have been really challenging,” said Ray, the project manager. “I’ve definitely had my share of EQUiSat nightmares.”

A number of last-minute problems, including a major issue with the satellite’s battery-charging system, made for lots of long hours for team members at the close of last semester. But in the end, Ray says, the team pulled together and delivered.

“It was hard to say, ‘Hey, I know you have three finals coming up and a paper due tomorrow, but we need you to come in and work on this,’” Ray said. “But it really pushed us. I think as a team we came out stronger.”

The first of the spacecraft’s final tests, which were done the first week of March, made sure it was made to the proper dimensional specs and would be compatible with the deployment apparatus aboard the ISS. A team from Nanoracks, a Houston-based company that deploys CubeSats, came to Providence to perform the test.

There were some nervous moments in Barus and Holley 195, where the test took place, but EQUiSat fit like a glove in the deployer. It was a huge moment for Lauren Haller, who milled the satellite’s chassis.

“It was great,” Haller said. “I’ve measured it so many times, but there’s always that little bit of worry that it’s not actually going to fit.”

All those worries evaporated in an instant when the chassis proved to be well within Nanoracks’ strictest tolerances.

In tribute to the team members who had come before, Ray asked if the Nanoracks team would fit test the prototype chassis that Hannah Varner had milled four years prior. It too was a perfect fit. Ray sent a picture of the test to Varner.

“I spent over a hundred hours making that first chassis my senior year, and Hunter knew it,” Varner said. “Every generation of new leadership brings their own energy to the project but also recognizes the amount of blood, sweat and tears the previous team member put in as well.”

The second of the final checks was a vibration test, to make sure EQUiSat’s systems would survive the rocket ride to space. The team traveled in a snowstorm to Connecticut, where a company had donated time on its shake table. After the big shake, the team ran a series of diagnostics to see if EQUiSat had survived.

Everything worked. After seven years of toil involving more than 100 Brown undergraduates, all systems are go for launch.

Many current and former team members are planning to be at Wallops Island in May for the launch, including Emily Gilbert, a former team member and now a Ph.D. student in astronomy at the University of Chicago.

"I wouldn't miss the launch for the world,” she said. “A number of alums of the project are planning on renting a house, and we will be watching the launch live. I know how much effort has gone into this project over the years, and I'm really proud of the work the group has done.”

But the launch isn’t an ending. It’s just the beginning for EQUiSat. And it’s a new beginning for Brown Space Engineering. The current team leaders, like the leaders who came before them, will pass team leadership to the next group of students, who are already making plans to build Brown’s second trip into Earth orbit.

[Editor's Note: This story has been updated to reflect changes in the launch date, which is currently set for May 20.]