PROVIDENCE, R.I. [Brown University] — Two years ago, Brown Class of 1979 alumnus Charlie Giancarlo presented students at the University’s School of Engineering with a grand design challenge.

Giancarlo wanted to fund the installation of a sculpture to be placed in front of Brown’s new Engineering Research Center. He envisioned something that would represent the rigor of engineering work, but have artistic beauty as well. He wanted something that people could touch and interact with, yet would last a long time, at least as long as the engineering building itself. Most importantly, he wanted it to be a means of telling time by tracking the sun — a sundial. He challenged students to come up with a striking design that met all those criteria and to then oversee its fabrication and installation.

A student group called Brown STEAM took up the challenge, and the result of more than two years of work — a stainless steel “noon mark” sundial measuring 15 feet long and 4 feet high — is being installed this week. The piece, titled “Infinite Possibility,” is the first permanent installation designed by students to be approved by Brown’s Public Art Committee.

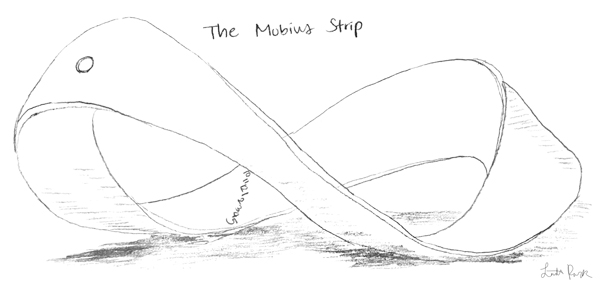

The sundial takes the shape of a Mobius strip, a loop with a half twist and age-old mathematical curiosity. Each day at 12 noon (11 a.m. during the winter months), the sun will shine through a small hole on one side of the structure, casting a bead of light on the inner surface of the loop. Over the course of a year, that bead of light will move across the surface with the position of the noontime sun over College Hill, tracing along a figure-eight-shaped diagram of the sun’s path called an analemma.

Elizabeth Austin, a junior engineering student and project co-leaders, says the piece reflects the nature of Brown’s educational ethos.

“I think ‘Infinite Possibility’ is very emblematic of the Brown experience because you have this opportunity to pull from different disciplines,” Austin said. “You can really engage with the campus and pursue something that really matters to you — a whole world of infinite possibilities that you can explore. I think that’s ultimately what this represents for me.”

Giancarlo says he’s thrilled that Brown students were able to answer his challenge.

"We wanted to make a statement about engineering at the University, which is a wonderful fusion of engineering, art and design,” Giancarlo said. “It worked out even better than I’d hoped.”

Finding a design

After Giancarlo presented his vision to the School of Engineering, Jennifer Casasanto, an associate dean in the school, started the processes of bringing students into the fold. Brown STEAM — an acronym meaning science, technology, engineering, mathematics and art — quickly stepped to the plate.

“STEAM found out about the project and said ‘we have the perfect team for this,’” Austin said. “We promote interdisciplinary learning through engineering and the arts.”

STEAM’s then-president tapped Austin and David Schurman, both first year students at the time, as project managers. The pair assembled a team of around 20 students to start brainstorming ideas and getting input from the broader Brown community. Eventually the team narrowed submissions to four final designs.

“All of them were quite interesting from a number of different perspectives and all very different,” Giancarlo said. But one stood out from the pack: the Mobius strip.

Unlike some other finalists, it didn’t have any moving parts, so people could interact with it with much less potential for damage. It was to be made from stainless steel, so it would be weather resistant and would last a long time. And the design itself made the statement that Giancarlo and the students were looking to convey.

Mobius strips have the fascinating property of having only a single continuous surface, something that Giancarlo and the students saw as evoking a sense of timelessness. It also looks a bit like the mathematical symbol for infinity, which combined with the infinity-shaped analemma that would be etched on the surface, served to unify the theme.

Linda Park, a senior computer science concentrator, came up with the Mobius strip idea.

“I started thinking about something that would have a flexible, organic shape and a seamless feel, and something that also spoke true to Brown’s Open Curriculum that is free and without constraints,” she said. “At that moment, the twisted Mobius strip and that figure-eight loop shape came to mind as the best mathematical and geometric form that would symbolize infinity. Putting them all together became the conception of the Mobius strip idea.”

The team then worked with a sundial expert named Bill Gottesman, who advised them on how their design might work as a sundial. The noon mark ended up as a natural choice. One wing in the Engineering Research Center blocks the sun from falling on the green space — Giancarlo Plaza — outside the building during the afternoon, so a sundial that tracked the sun over the course of a day wouldn’t work. But the plaza does get direct sun at noon, so a noon mark could be used to track the position of the sun through the year.

Design and fabrication challenges

Finalizing the design was far from the end of the project.

“Back when we started, we thought it would be a semester designing the thing and then we’d hand it off to the engineering administration and they’d handle the rest,” said Schurman, now a junior computer science and philosophy concentrator and the lead project manager.

Instead, Giancarlo and the School of Engineering’s leaders encouraged the students to see the project through fabrication and installation, learning valuable large-scale project management skills along the way.

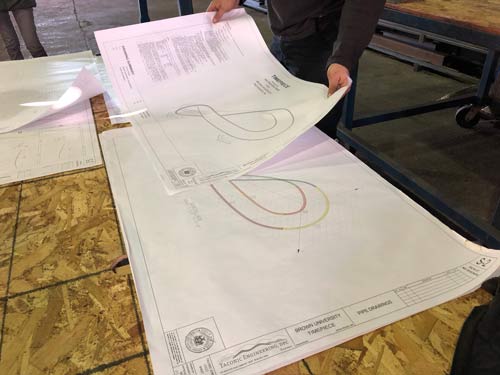

Realizing Park’s design as a stainless-steel structure was no easy task. The first problem cropped up quickly: It’s very hard to render a Mobius strip in the CAD (computer-aided design) drawings that a fabricator would need to build it.

“I approached my CAD professor asking how you create technical drawings,” Austin said. “He joked that a Mobius strip was always the example he gave to his students of what not to put in a technical drawing because of challenging aspects of the shape.”

But eventually, in consultation with a few outside advisors, they managed to produce their renderings. From there, Sultz Fabrication in New York was chosen to put the piece together. The structure consists of a skeleton made of steel tubes, covered by stainless steel plates to make a smooth, reflective surface. Combined with the two thick glass pedestals on which the structure will stand, the entire piece weighs around 1,200 pounds.

“Even just making a structure that weighs 1,200 pounds and can support its own weight was a challenge in and of itself,” said Ethan Mok, a senior engineering concentrator and project team member. “There are a lot of cross beams and braces in between the pipes and the skin to make sure it doesn’t collapse inward on itself as well.”

Another issue was the analemma — the track of the sun throughout the year — that was to be etched onto the inner part of the loop. There were no existing examples that the students could find of an analemma being projected on a curved surface.

“The shape is entirely different when it’s on a curved surface,” Giancarlo said. “So all of that had to be carefully worked out.”

A learning experience that lasts

All of those challenges, as well as the experience of working with Brown’s Public Art Committee to consider the aesthetic, material and audience presentation of the piece to ensure that the piece was ready for installation, turned a “semester project” into a two-and-a-half-year odyssey. The students say, however, that it could hardly have been more rewarding.

Park says she’s grateful for the experience of thinking through her design, because it led her to so many intellectual corners of College Hill.

“We had to consult the visual art department to get suggestions on which material works better between stainless steel and aluminum,” she said. “We had to consult the applied math department to talk about the feasibility of projecting an analemma on a curved surface, and finally the computer science department to create a rendering of my animation that would show the movement of the sun around the sculpture. This project was the chance to really show what could be possible through the Open Curriculum and an interdisciplinary approach.”

For Schurman, the most rewarding part was learning to balance the artistic and scientific considerations to get the project completed.

“I think there was a bit of tension in the beginning between the engineering side and the arts side,” Schurman said. “Both sides had equally valid and helpful considerations — it was just a matter of helping the other people see why. I hope to work eventually in areas that are involved in projects like this and these sorts of collaborations. So I hope this will come in handy.”

Casasanto, who advised the students throughout the project, agreed that working with the Public Art Committee was important and illuminating.

“That was one of the most unexpected and wonderful aspects of this project,” she said. “We learned so much from them, they were great advisors and champions of this project, and I think our students impressed them with what they were able to do.”

All of the students agreed that having a chance to work on something that will leave a lasting legacy at Brown is a truly special experience.

“Something like this was explicitly designed from day one to last for 50 to 100 years,” Mok said. “Let’s be optimistic and say it lasts 100 years; it will most likely outlast me. That’s really cool to see that something that you put [so much] into — your thoughts, your ideas — will then outlast you. That’s definitely something that I would like to strive for in the rest of my engineering life.

“I’ve got a legacy forever now.”