PROVIDENCE, R.I. [Brown University] — As medical experts warn that the COVID-19 pandemic could create a shortage of live-saving ventilators, a team of faculty and students from Brown University’s School of Engineering has been hard at work on a solution that may help in a crisis.

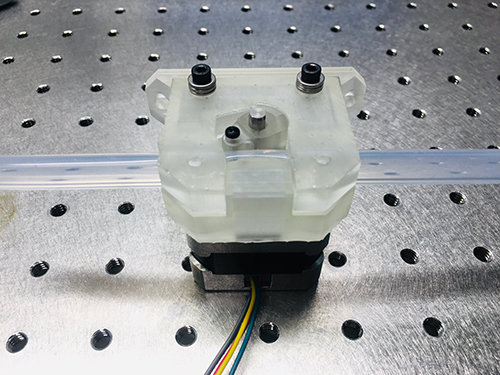

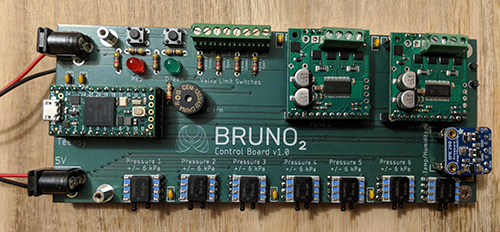

The team has designed a do-it-yourself ventilator, dubbed BrunO2, that can be quickly assembled using 3D-printed and readily available parts. The design targets specifications developed in consultation with medical experts yet can be easily deployed in resource-strapped situations. The idea is to make the design of the system and its custom components freely available online, so anyone can download the plans and make their own.

“The important thing is that one should be able to produce it locally,” said Roberto Zenit, a professor of engineering at Brown who co-led the effort with fellow faculty member Daniel Harris. “There is a package of information that can be downloaded — in Texas, or in South America, or in West Africa — where users should be able to purchase the materials, print the components and put it together.”

The project began as a submission to the Code Life Ventilator Challenge, an international design initiative based out of McGill University in Montreal and aimed at helping to alleviate potential ventilator shortages. Neither Zenit nor Harris had previous experience in making ventilators. But as experts in fluid dynamics, they did have some experience moving air around. And Harris’s lab specializes in rapid prototyping of custom-made tools and devices used in fluid dynamics experiments. He routinely makes those designs available to other researchers.

“This was naturally within that spirit,” Harris said. “I believe that to make things progress in science, whether it’s health or our own fluids research, that we should be collaborating globally.”