PROVIDENCE, R.I. [Brown University] — Traumatic brain injuries are a pervasive yet elusive health problem, affecting millions worldwide. According to recent data, an estimated 2 million people experience a traumatic brain injury each year in the U.S. From kids and adults on playing fields, to soldiers and sailors on battlefields, the risk of brain injury includes everything from mild concussion to chronic traumatic encephalopathy (CTE) — a progressive disease often associated with football players who suffer repeated blows to the head.

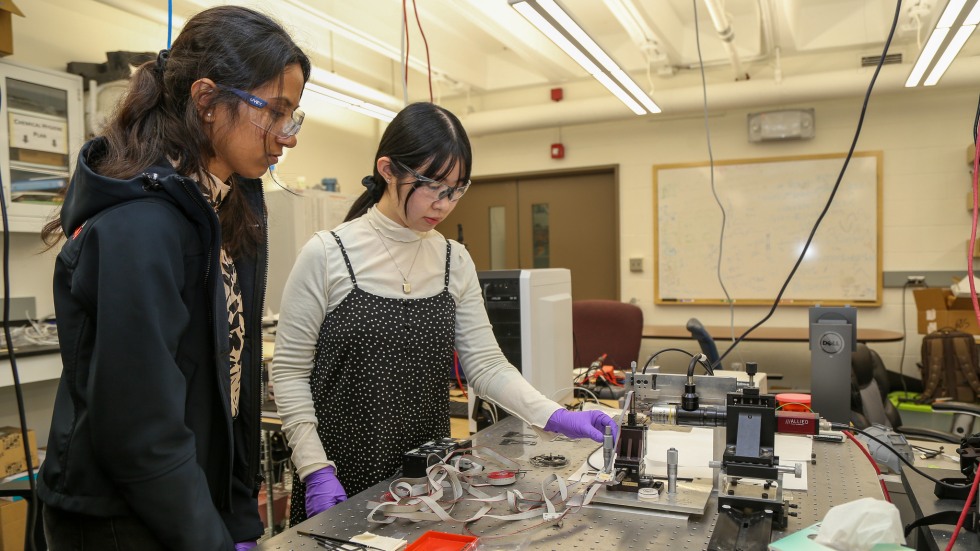

Despite alarming trends about these types of injuries, they remain frustratingly difficult to diagnose and even harder to prevent. The applied mechanics laboratory at Brown University’s School of Engineering is part of an effort to develop solutions. The 10-person team — which includes postdoctoral researchers, graduate and undergraduate students — is led by Haneesh Kesari, an associate professor of engineering. The lab’s focus is centered on traumatic brain injury and blunt trauma the body can endure.

“We usually first become aware of injury through us feeling pain,” Kesari said. “In fact, through most of our evolutionary history, injury to the brain came via the skull, such as during falls or blows to the head, and not directly to the brain itself by means of chronic violent shaking of the head. It’s reasonable to speculate that this is one of the reasons why the skin and the muscles around the skull have pain receptors, but the brain itself does not. The lack of pain receptors inside the brain’s tissues means it is not possible to ‘feel the pain’ of mild traumatic brain injury, at least not in the traditional sense that we do with other types of traumatic injuries — making it particularly insidious.”

To address that challenge, the Kesari lab has been developing wearable devices for use in experimental settings to measure the stresses and strains associated with blows to the head, blast trauma, or violent thrashing of the head and neck. Working with collaborators at Brown and beyond, the U.S. Office of Naval Research-funded effort is part of a long-term project called PANTHER that is studying brain and bodily injury. It’s led by researchers at the University of Wisconsin-Madison and includes Kesari’s lab as well as Brown researchers Diane Hoffman-Kim and David Henann.